Limestone pelletizing: A technical overview

Preliminary Note on Terminology

In the international fertilizer industry, the terms “granulation” and “pelletizing” are used synonymously to describe the agglomeration of fine-grained materials. Accordingly, the resulting products are referred to as either “granules” or “pellets.” The choice of terminology in this publication follows the established and well-known SCARABAEUS pelletizing disc, and for consistency, the term “pelletizing” is used throughout the remainder of the article.

Introduction to limestone and its uses in agriculture

Limestone (calcium carbonate, CaCO₃) is a vital agricultural additive that helps regulate soil pH, improve soil structure, and increase nutrient availability. When applied to acidic soils, limestone raises pH, allowing essential nutrients to become more accessible to plants.

Limestone used in agriculture is often pelletized, which involves binding the finely ground limestone into small, uniform pellets. Pelletized limestone offers several advantages over powdered forms, including easier handling, reduced dust, and improved spreadability.

The pelletizing process

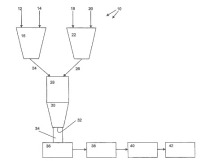

Limestone pelletizing is a critical process for transforming finely ground calcium carbonate (CaCO₃) into durable pellets that are easier to handle and apply, especially in agricultural settings. The process leverages advanced technologies in mixing, agglomeration, and drying to produce consistent, high-quality pellets that enhance soil health by regulating pH levels, improving soil structure, and increasing nutrient bioavailability. Haver Engineering GmbH, an associated institute of the TU BERGAKADEMIE Freiberg and the dedicated R&D center for Haver & Boecker Niagara, utilizes innovative laboratory tools to conduct feasibility studies on raw materials and refine process flows for limestone pelletizing. These efforts optimize both technical performance and economic efficiency, assisting customers in selecting the most suitable processing equipment for their needs. Through these optimizations, limestone pelletizing becomes not only more efficient but also highly adaptable to various application requirements, ensuring consistent pellet quality and enhanced functionality in diverse settings.

The pelletizing of limestone involves multiple steps, each tailored to achieve high mechanical strength, optimal pellet size distribution, and resistance to breakage and dust formation. These steps include mixing, agglomeration, drying, and screening, all of which are carefully controlled to ensure uniformity and quality.

1. Mixing and binder addition: The process begins with finely ground limestone, which is mixed with a binding agent, typically calcium lignosulfonate, molasses, or other organic binders. These binders help the limestone particles adhere to each other, forming a cohesive pellet. The choice of binder is significant, as it impacts both the structural integrity and the environmental compatibility of the pellets. The binder also impacts the durability of the pellets, influencing their resistance to mechanical stress during handling and application.

Binder effect on pellet properties: Calcium, sodium, ammonium, magnesium, or potassium lignosulfonate, for example, enhance pellet strength and provide a cohesive bond, reducing the amount of dust produced during handling and transportation. The binder also plays a role in the drying process, as it influences moisture retention and evaporation rates

Mixing equipment: There are high-performance mixers on the market that evenly distribute the binder throughout the limestone powder, ensuring homogenous pellet formation. The mixers are designed to handle a wide range of binder types and allow for precise adjustment to achieve targeted pellet characteristics

2. Agglomeration: Agglomeration is the process of forming the limestone mixture into small, uniform pellets. The method chosen for agglomeration affects the shape, size, and density of the final product, which are crucial parameters for specific agricultural applications.

Disc pelletizers: One of the most common methods is disc pelletization, where the limestone and binder mixture is added to a rotating disc. The rotating motion helps the fine limestone particles to nucleate and grow into pellets as they roll along the disc’s surface. Disc pelletizers allow for excellent control over pellet size and produce highly spherical pellets with a narrow size distribution. The Niagara’s disc pelletizers are designed to facilitate precise adjustments in angle, speed, and moisture content, enabling the production of pellets tailored to specific agronomic needs

Drum pelletizers: Another method involves drum granulation, commonly used by higher throughput requirements. Here, the limestone mixture is fed into a rotating drum, where it tumbles and forms pellets. This method typically requires additional equipment, such as a mixer or a pre-moisturizing unit, to ensure the mixture has the right consistency. These operate by tumbling the limestone mixture within a rotating drum, promoting pellet formation through a combination of rolling and layering. But drum granulation may produce a wider size range

Roller compaction: Another method involves compressing the limestone mixture between two rollers to form dense, uniformly sized pellets. This technique is ideal when strength and compactness are priorities. This method is particularly suitable for applications requiring high mechanical strength in pellets, such as in industrial lime products. But the specific energy consumption is very high

The agglomeration method chosen affects the shape and size distribution of the pellets. Disc pelletizers tend to produce more uniform, round pellets, while drum pelletizers may produce a wider range of shapes and sizes. This uniformity is important for certain applications, such as broadcast spreading, where consistent size aids in even distribution.

3. Drying and cooling: Once the pellets are formed, they are dried to remove excess moisture. Drying is essential to enhance pellet hardness and reduce susceptibility to degradation during storage and transport.

Thermal drying: Once formed, the pellets are typically dried to remove excess moisture and increase their strength. Drying reduces the likelihood of pellet degradation during handling and application. Depending on the process, thermal drying or air drying may be used. Thermal drying often involves heating the pellets to a specific temperature, which hardens the binder and enhances the structural integrity of the pellets: Thermal dryers, including rotary kilns and fluidized bed dryers, are typically used. These systems heat the pellets to an optimal temperature, evaporating moisture while hardening the binder. Common drying systems feature precise temperature controls, ensuring that the drying process does not compromise the binder’s integrity or cause thermal shock to the pellets, which can result in cracks or breakage

Cooling: After drying, the pellets are cooled to ensure they maintain structural integrity. Rapid cooling is sometimes necessary to prevent further moisture loss, which could cause shrinkage and cracking. Cooling units integrated into pelletizing systems gently reduce pellet temperature, helping to preserve the desired physical characteristics of the final product.

Advantages of pelletized limestone

Pelletized limestone offers several technical and economic advantages, particularly in terms of ease of handling and application:

Reduced dust: Pelletized limestone is far less dusty than powdered forms, which minimizes material loss and improves air quality for workers

Enhanced flowability: Pellets have better flow characteristics, allowing for smoother handling in automated equipment and storage systems

Improved spreadability: The uniform size and shape of pellets facilitate precise application, whether by hand or machinery. This even distribution ensures that all areas receive adequate coverage

Increased nutrient efficiency: Due to its gradual breakdown, pelletized limestone provides a sustained release of calcium and magnesium, maintaining soil pH over longer periods compared to faster-dissolving forms

The experience of Haver Engineering in the Limestone Pelletizing

Haver Engineering has successfully implemented limestone pelletizing solutions across various industries, demonstrating the versatility and reliability of their approach. By customizing their equipment and processes to meet specific customer needs, Haver Engineering has enabled companies to improve operational efficiency, reduce costs, and minimize environmental impacts. Below are some notable case studies that highlight the effectiveness of Haver Engineering’s limestone pelletizing knowhow in both agricultural and industrial contexts.

Agricultural lime for soil remediation

A large agricultural producer approached Haver Engineering for a solution to improve the handling and application efficiency of agricultural lime. The challenge was to convert finely ground lime into dust-free pellets suitable for mechanical spreading over extensive farmland. Haver Engineering implemented their disc pelletizing technology, which produced 2–4 mm pellets with excellent strength and resistance to disintegration. This product not only reduced dust and improved handling but also offered a slow-release effect, which provided long-term pH adjustment benefits for the soil.

The customer reported a 30% reduction in application time and a significant decrease in material loss due to the dust-free nature of the pellets, translating into cost savings and improved operational efficiency.

Pelletizing of limestone for industrial use

An industrial operator required a highly durable limestone pellet for use in chemical processes. Haver Engineering utilized their advanced technology, combined with a specialized binder, to produce pellets with enhanced mechanical strength. This process yielded pellets capable of withstanding the rigors of high-temperature applications without breaking down, which was crucial for maintaining process efficiency.

The implementation of Haver’s technology resulted in a product that reduced maintenance requirements and provided more consistent performance in the client’s processes, leading to a 20% increase in operational uptime.

Technical considerations

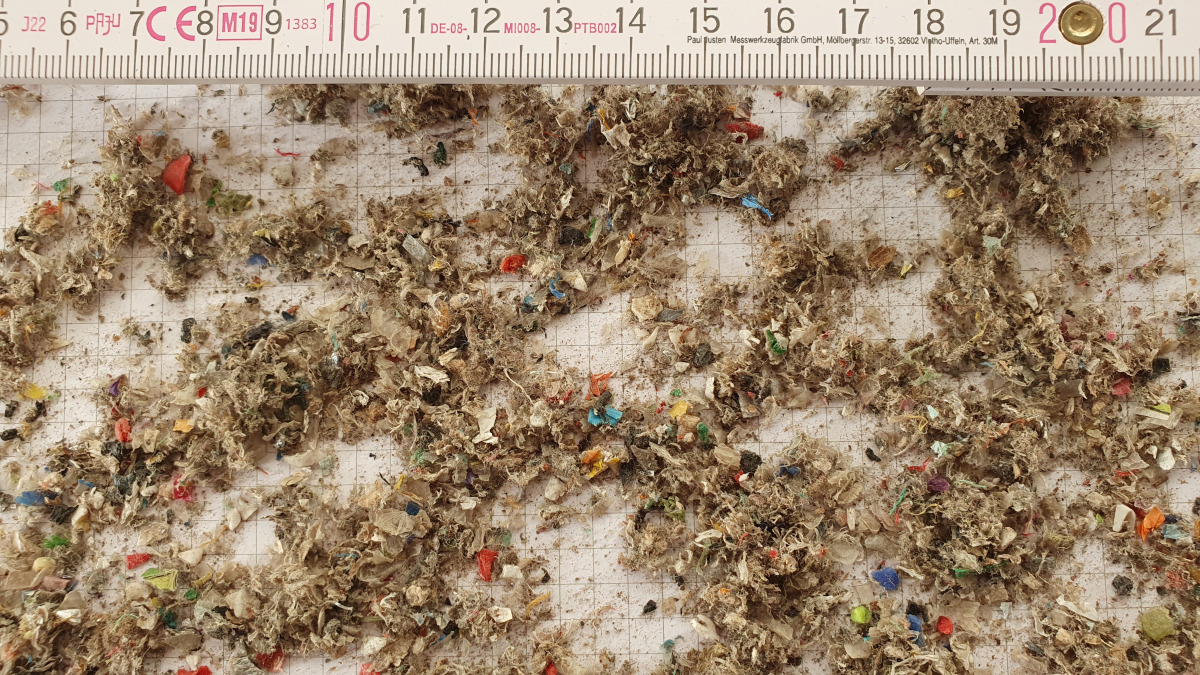

Producing high-quality limestone pellets requires careful attention to several technical aspects that affect the product’s performance during handling, storage, and application. These considerations ensure that the pellets not only meet industry standards but also maintain their integrity and effectiveness in the field. Key factors include the physical properties of the pellets, such as strength and abrasion resistance, as well as their granulometric and chemical characteristics, all of which contribute to the pellets’ durability and functionality in diverse agricultural and industrial settings.

Pellet strength and abrasion resistance

The physical properties of limestone pellets, such as strength and abrasion resistance, are crucial for handling and transportation. High-quality pellets withstand stress during transport and application without breaking down, which prevents dust formation and loss of material. Agglomeration methods and binder selection directly impact these properties. For instance, binders like molasses or lignosulfonate not only enhance pellet durability but also improve their structural resilience during the drying phase.

Granulometric and chemical properties

Pelletized limestone is commonly produced in diameters ranging from 2 to 20 mm, with most applications favoring pellets between 1 mm and 4 mm. The uniform size is especially important for agricultural use, where even particle size aids in consistent application and absorption into the soil. Additionally, the chemical composition of the limestone, including calcium and magnesium content, can be optimized during the pelletizing process to meet specific soil amendment needs.

Economic and environmental impact

Reducing dust and particulate emissions during limestone application is a significant environmental benefit of pelletized products. Haver Engineering’s dust-free pellets decrease airborne particulate matter, improving air quality around application sites. Furthermore, their systems are designed to minimize CO₂ emissions associated with energy use in the pelletizing process, aligning with global sustainability goals. For example, by using their disc granulation method, Haver Engineering has helped customers achieve an average reduction of 1500 t of CO₂ emissions annually.

Energy consumption

The pelletizing process consumes both electrical and thermal energy, with disc pelletizers generally being more energy-efficient than other methods. A typical setup for disc pelletization might consume around 7.2 kWh/t for electrical energy and 100 kWh/t for thermal energy. In contrast, other processes, like roller compaction, could demand higher electrical energy, reflecting different levels of energy efficiency and operational costs.

Carbon emissions and cost efficiency

The carbon footprint of limestone pelletizing operations varies depending on the specific agglomeration technique used. Disc pelletizers, for instance, generally have lower CO₂ emissions compared to other methods, making them a more environmentally friendly option. Additionally, lower energy costs and emissions can translate to more competitive pricing for pelletized limestone products, which is a crucial consideration for large-scale agricultural applications.

Conclusion

The pelletizing of limestone is a sophisticated process that transforms fine limestone particles into durable, easy-to-handle pellets suitable for agricultural applications. By improving spreadability, reducing dust, and providing a consistent release of nutrients, pelletized limestone offers considerable agronomic benefits. Technical choices around the agglomeration method, binder type, and drying approach impact both the quality of the final product and the overall cost-efficiency of the process. As such, limestone pelletizing not only meets current agricultural needs but also contributes to more sustainable and efficient soil amendment practices.

These agronomic and environmental benefits underscore the importance of technical precision in the limestone pelletizing process. Selecting the right agglomeration method, binder type, and drying technology ensures that pelletized limestone achieves the desired quality and cost-efficiency, while also addressing the growing demand for sustainable soil amendments. Recognizing this need for both performance and sustainability, Haver Engineering has emerged as a leader in limestone pelletizing technology. Through a combination of advanced equipment, binder technologies, and optimized drying processes, Haver Engineering provides tailored pelletizing solutions for various applications, from agricultural lime to industrial-grade pellets. Their proven track record in delivering high-quality products, as evidenced by successful case studies, underscores their commitment to innovation and sustainability in pelletizing technology. By integrating advanced equipment and optimized processes, Haver Engineering tailors its solutions to meet specific agricultural and industrial applications, demonstrating a strong commitment to innovation and environmental stewardship in pelletizing practices.