Two coal/petcoke grinding plants for Mexico

Loesche has now sold two of its biggest coal/petcoke grinding mills for the cement industry in Mexico. These are to be used in the cement plants of the group Cooperativa La Cruz Azul, S.C.L. – on the one hand in the plant in the province of Hidalgo, 80 km north of Mexico City, and on the other in the Lagunas plant in the province of Oaxaca in southern Mexico. In each of these cases, the Cruz Azul group is establishing a new production line here. At the Hidalgo plant with a production capacity of 2.8 million t/a, not only the new line, but also all existing kiln lines are to be supplied with ground pet coke from the Loesche mill.

In addition to the mill with a capacity of 65 t/h, Loesche will also be supplying the complete plant equipment including process gas filters, mill fans, inertisation units, explosion protection valves, kiln gas cyclone separators, feed screw and drag chain conveyors as well as the complete electrotechnical equipment. In addition, the scope of supply here also includes the complete detail engineering for the steel construction and for the concrete construction.

Vertical roller mills that grind petcoke have been Loesche’s field of specialisation for decades. This is one of the reasons why La Cruz Azul, S.C.L. has opted for Loesche over other longstanding mill suppliers. To add to this, at the end of 2016 Loesche delivered one complete cement grinding plant with a Loesche mill type LM 46.2+2 CS that is currently being put into operation for the Tepezalá cement plant of the customer CYCNA, who also belongs to Cruz Azul Group. In doing so, Cruz Azul Group now places its trust in innovative Loesche technology at a total of three of its plants (Hidalgo, Lagunas and Tepezalá).

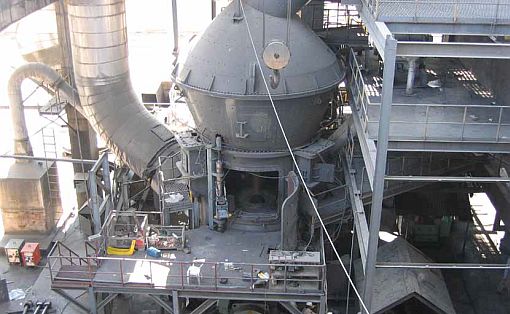

The two new coal/petcoke mills in the cement plants of La Curz Azul S.C.L. are based on the proven mill design with four rollers and are characterised by their modular construction as proven in the cement industry. These mills are perfectly suited for processing petcoke fuel for heat generation in kiln furnaces and precalciners. The principle of these Loesche grinding mills is based on a horizontal grinding table with segmented grinding plate and conical rollers which are arranged at a 15° angle to the grinding table ensuring efficient and low energy consumption grinding. The hydraulic swinging-out device for the rollers ensures a simple and fast change of grinding parts.

Petroleum coals, as they are used at La Cruz Azul, S.C.L., must be finely ground like anthracite coals due to the low level of volatile matters (between 1-15 %) in order to obtain the necessary surface for the optimal combustion of the product. To do this, Loesche coal/petcoke mills are equipped with an efficient hydraulic system for grinding pressure control and mechanical stop buffers which prevent the tires from touching the grinding plate upon reaching the necessary low level of the grinding bed. Furthermore, the control of the grinding table speed by means of a frequency converter allows the bandwidth of the hydropneumatic spring system to be expanded. This ensures that product quality is consistent. Commissioning of the new grinding plants is planned to take place in mid-2019.

//www.loesche.com" target="_blank" >www.loesche.com:www.loesche.com