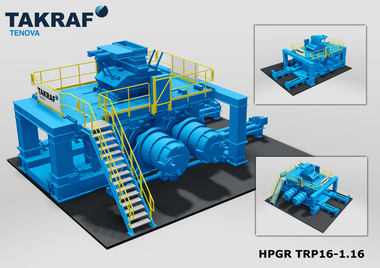

Wear-free operation of the rolls in the high-pressure grinding roll in Lägerdorf

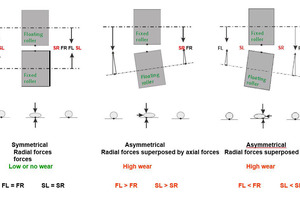

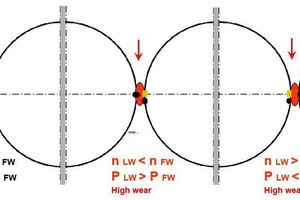

With a variety of considerations, this paper sees the wear of the grinding rolls as a problem of the geometry of the coupling of the energy for the destruction of the grain in the bed of material. There are also many other considerations [6].

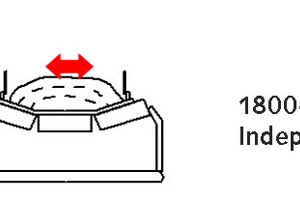

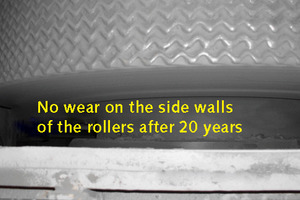

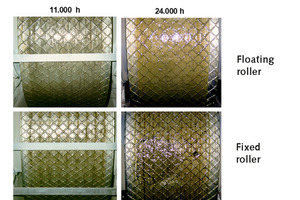

In Lägerdorf, the mill was converted and operated in accordance with the established geometric rules. This meant that the rolls had to be replaced only after a service life of 20 years. This is generally thought to be impossible.

Furthermore, after replacement of the self-aligning roller bearings, the dismounted rolls can be used further. The reader‘s attention is therefore drawn firstly to the decisive data collected in Table 1, with the associated keywords.

1 Introduction

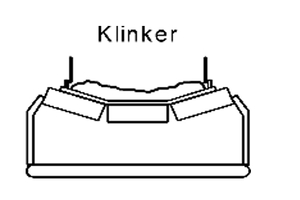

Portland cement has been produced in Lägerdorf, in northern Germany, for almost 160 years. The main raw material is pit-wet chalk, which is extracted by means of open-pit mining. The raw materials (chalk, sand, clay and iron oxide) are prepared in the semi-wet process and are pre-dried and calcined in the three-stage cyclone preheater tower with integrated flash dryer. Sintering to cement clinker takes place in the rotary kiln.

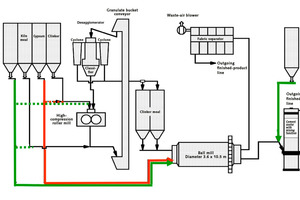

For cement grinding, a large ball mill and a combi grinding plant consisting of a high-pressure grinding roll and a downstream open-circuit ball mill are...