prepol® SC – one of the most effective ways

to utilize wastes in the cement plant

In 2025, according to UN figures, more than 8.1 billion people will live on the earth and produce around six million tons of waste a day. In the future, resources must be used more efficiently and industrial goods must be produced in a more environmentally friendly way. The cement industry provides one example of how this could happen: Through the use of the prepol® SC combustion chamber developed by thyssenkrupp, coal, gas and oil as primary energy sources can be replaced 100% by alternative fuels – a sustainable contribution to conserving resources and reducing CO2 emissions.

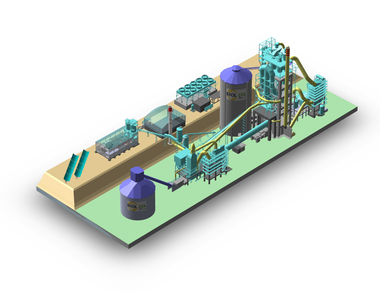

One of Thailand’s largest cement producers, TPI Polene Public Company (TPIPL), has been operating thyssenkrupp cement plants in Saraburi Province for more than 30 years. For three kiln lines with a total daily output of up to 27500 t, TPIPL will in the future be relying on prepol SC technology. When fully implemented, it will be one of the world’s biggest industrial-scale applications for the thermal utilization of alternative fuels in cement plants. In addition to reducing operating costs, TPI Polene sees this investment as an important part of its corporate citizenship efforts.

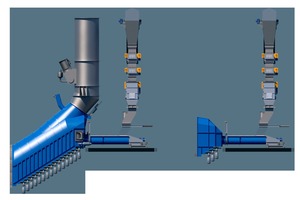

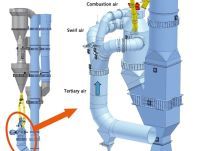

Low-grade alternative fuels, which previously had to be sent to landfill or waste incineration plants, can now be used with much greater efficiency in the production of cement. How is this pos-sible? The prepol SC is an add-on for the prepol precalciner. On a simple combustion grate, waste can burn for more than 1000 seconds at high temperatures. Compared with conventional calciner technology with a maximum residence time of seven seconds, the prepol SC opens up a new dimension for the thermal utilization of a large number of alternative fuels.

In addition to conserving natural resources and mitigating emissions, operating costs can also be significantly reduced. This is made possible by the use of a wide variety of waste types, low requirements on the quality of the waste and low pre-processing costs. Another factor is that 80% of the thermal energy generated in the combustion chamber can be used directly in the process. And the ash that remains is also recycled.

Due to its modular design, prepol SC technology can be easily integrated into existing cement plants. As there are no moving parts in the combustion chamber, the plant has high availability and can be simply maintained. International production of this proven machine technology is possible.

“By introducing and retrofitting our sustainable solutions, operators of cement plants can gradually reduce emissions from their facilities – and thus move closer to our common goal of a green cement plant”, says Pablo Hofelich, CEO BU Cement Technologies.

Worldwide cement production is responsible for around seven percent of global CO2 emissions. As part of its climate strategy, thyssenkrupp is pursuing the goal of reducing emissions from the use of its products by 16% by 2030. prepol SC technology contributes to this goal: “Optimal thermal utilization of wastes can reduce CO2 emissions by up to 14%.”

Sustainable, cost-effective and simple – three characteristics that describe thyssenkrupp’s products for the cement sector.

Urbanization, digitization, global-ization and climate change are altering people’s lives. As a global industrial company, thyssenkrupp with its resource-friendly products and processes has a particularly powerful lever to sustainably reduce greenhouse gas emissions. Concrete made from cement is one of the most important building materials for Germany and the world’s economic development. With prepol SC technology, thyssenkrupp offers the most effective way to utilize all types of waste in cement plants economically and sustainably.

//www.greencementplant.com" target="_blank" >www.greencementplant.com:www.greencementplant.com