A contribution to decarbonisation in the building materials industry through resource- and climate-friendly gypsum building products – with examples from research –

A quantitative assessment of the environmental impact of the building materials industry in Germany and the current regulatory framework make it urgent to reduce resource consumption and climate impact. Innovative and practical product developments show that gypsum can be a climate-friendly alternative to CO2-intensive building materials.

1 Introduction

Since the Club of Rome’s study on the limits of growth 1972, whose calculations have been in the meantime repeated and confirmed with updated data, the issue of resource conservation has been present in the public consciousness. The repeated international climate commitments of the United Nations reflect the urgent need for action against climate change since the Kyoto Protocol of 1997. However, it is only with the creation of comprehensive regulations that industry and the economy are now preparing for a far-reaching restructuring. The urgency and brevity of the required implementation periods now present the building materials industry with fundamental challenges. European initiatives such as the Green Deal (2021), the amended EU Buildings Directive (EPBD 2024) and the EU Construction Products Regulation (EU-CPR 2025), together with the Substitute Building Materials Ordinance (EBV 2023) and the German Circular Economy Act (KrWG 2024), form a dense network of requirements. Of particular significance are the EU Buildings Directive, amended in 2024, and the EU Construction Products Regulation, which came into force in 2025, which for the first time provide for the calculation and disclosure of cumulative life-cycle emissions (“life-cycle GWP”). These developments are creating new market mechanisms for climate-friendly building materials through sustainability reporting (2025: SMEs from 2028), emissions trading and mandatory disclosure of CO2 and material footprints.

2 Sustainability goals and opportunities – status quo

In order to achieve the 2030 climate protection target, the consumption of energy and greenhouse gas-emitting raw materials and fuels in Germany would have to be reduced by 65%. Climate neutrality is to be achieved by 2045 [12]. So far, industrial CO2-emissions from industry have hardly changed (-8% in 30 years) despite reduced coal use [10]. In the construction industry, demand for raw materials is expected to rise. In order to counteract climate change, attention must now be paid not only to energy measures in reconstruction, new construction and utilization, but also to reducing CO2-emissions in the production of building materials. The Federal Institute for Research on Building, Urban Affairs and Spatial Development (BBSR) calculates that the consistent use of resource-efficient construction methods in new buildings could save up to 7 million t of CO₂-emissions. As part of the federal government‘s sustainability strategy, the Resource Efficiency Programme (ProgRess I-III 2012-2023) includes the reduction of material consumption, the substitution of greenhouse gas-intensive materials, the improvement of material properties and the increased use of recycled materials to increase resource efficiency along the value chain [7, 9, 13].

In the construction industry, the use of recycled building materials still plays a minor role in the circular economy – not least due to a lack of availability, but also due to cautious demand in tenders and a whole list of obstacles, ranging from resentment, uncertainty about the end of waste properties and the associated insurmountable bureaucratic hurdles, the lack of established logistics, sufficient recycling centres, the lack of a national information data system, unestablished take-back systems and much more. However, even with maximum effort, the achievable quantity of recycled building materials can only cover a fraction of the demand for raw materials. In addition, the sorting of construction waste requires further research with increasing automation and complex digital detection, and, above all, the manufacture of building products from recycled building materials, right through to quality assurance. [1, 15, 17, 31]

The construction and building materials industry in Germany accounts for 60% of total raw material consumption and the largest waste stream from new construction, renovation and demolition, and therefore bears a great responsibility for resource issues and climate protection [39]. The industry accounts for around 90% of total mineral raw material consumption, at around 530 to 600 million t/a, and at the same time generates 220.6 million t of mineral construction waste [3].

The climate impact of the construction industry associated with the consumption of raw materials and fuels is a decisive lever for CO2-reduction. Based on a national Global Warming Potential (GWP) of 831 million t of CO₂ equivalents (2022), the construction and use of buildings account for almost half of all German greenhouse gas emissions, at 398 million t of CO₂ equivalents. One third (133 million t of CO2-equivalents) of these emissions are attributable to the building materials used [16, 24, 29].

Concrete is the most commonly used building material in Germany, with estimated* 70 million t used annually in building construction (*assumption: concrete share corresponding to the cement consumption distribution of approximately 66% for the construction of buildings), which is associated with significant CO₂ emissions of more than 20 million t (according to researched data, CO₂ equivalents amounted to 16 million t of CO₂ eq. in 2022 [16, 29]).

The concept of urban mining considers the material used in construction as an anthropogenic deposit and potential raw material resource. However, the practical implementation of reuse and recycling will be difficult to achieve. The increasing use of composite materials, plastics and alloys makes selective dismantling and recyclability more difficult. Design for disassembly for modular and material-selective dismantling and single-type recycling has so far only been used to a limited extent in planning practice. The recycling rate for building materials without downcycling therefore remains low [47, 57].

In order to meet the requirements for a methodologically sound life cycle assessment of buildings (Environmental Product Declaration - EPD), it is necessary to consider the entire material cycle (perfect loop), including all building materials used. However, according to DIN EN ISO 14044, impact categories such as climate change, resource depletion or ecosystem damage potential, as well as the life cycle phases considered, are freely selectable. In practice, only the life cycle phases of production and end of life (see Table 1) are typically considered separately for building materials in a life cycle assessment, with specific system boundaries and allocation depending on the state of the art at the time of calculation. Unfortunately, this segmented and still inconsistent approach does not provide an optimal basis for building life cycle assessments, as the used basis for calculation for the construction products are often not directly comparable [8, 22, 53, 59].

3 Decarbonisation potential of gypsum building materials

3.1 Context

A key measure for decarbonisation in the building materials industry is the substitution of greenhouse gas-intensive mass-produced building materials such as cement and lime with non-carbonate alternatives with comparable functional properties. This substitution reduces the amount of fuel and energy required at significantly lower process temperatures and avoids the decarbonisation of calcium carbonates. In this context, calcium sulphate-based construction methods show potential applications in the interior construction of buildings. The binder are produced at low firing temperatures (140 to 180 °C for calcium sulphate hemihydrate and approx. 700 to 800 °C for thermal anhydrite) with the release of water instead of CO2. CaSO4 building materials are completely and repeatedly recyclable. Accordingly, a total of approximately 3.1 million t of CO2 eq. were recorded for burnt gypsum in Germany in 2022 (of which 0.62 million tonnes of CO2 eq. were from gypsum plasterboard production (GPB) [14]). By limiting the variety of materials and designing for recycling, calcium sulphate-based building materials offer nearly loss-free recycling in accordance with the cradle-to-cradle principle.

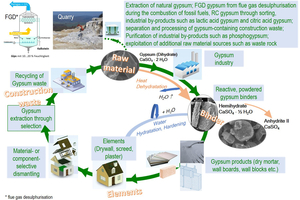

With a gypsum requirement of around 10 million t/a in Germany, half of which was covered by gypsum and anhydrite rock and half by FGD gypsum in 2022, around 65% is processed into calcium sulphate building materials and products and around 16% is used as a setting regulator in cement. The most important gypsum products in the construction and building materials industry include plaster of paris, plasterboards and other drywalls, interior plasters and self levelling floor screeds. Other applications can be found in medicine, food and agriculture [2, 3].

Gypsum from flue gas desulphurisation (FGD gypsum) will become increasingly scarce due to the shutdown of coal-fired power plants by 2038 [32] (28% less in 2023 than in 2022) [3]. While 50 to 70% of demand could be met by FGD gypsum until 2018, this will fall to only 10-40% by 2050 [18].

3.2 Gypsum construction waste and Gypsum recycling

In Germany, a large proportion of gypsum-based building materials are disposed of in landfills at the end of their life, mixed with construction waste [37]. Only some of the gypsum-based construction waste is recorded. This mainly includes plasterboard (GPB) and other gypsum boards from offcuts during installation and the nearly single-type dismantling of drywall components. In 2020, 1.2 million t of dismantled GPB were expected after a life of 40 years, which could double to 2.4 million t by 2040 [52]. In addition, 0.2 to 0.4 million t of GPB offcuts would have to be added (assuming 10-20% of the 2 million t of GPB installed in 2020 and 2023). However, the recorded amount of gypsum waste is only 0.6 to 0.7 million t/a [33]. Of this, 40 to 55% is landfilled (disposed) and the rest is sent for so-called recycling (further use of waste). Some of this is used as sewage sludge cover in neighbouring Eastern European countries (plasterboards from German production is needed in large quantities for the remediation of uranium sludge ponds from uranium processing MAPE in the Czech Republic [4]) or transferred to disused mine tunnels and similar sinks [3, 52].

Gypsum plaster and calcium sulphate screeds are not included. They are currently part of mixed construction waste. A significant part of gypsum-containing material is mixed with other mineral construction and demolition waste, such as masonry rubble, and sent to landfill. Because used moulds from the ceramics industry are listed under a separate waste code (AVV No. 10 12 06), these quantities are added to gypsum-containing construction waste (AVV No. 17 08 02), although their quantity is also not recorded. Our own research shows that used plaster moulds from roof tile production must amount to around 11000 tonnes (based on 600 million roof tiles per year). Internal recycling of offcuts from plasterboard production, which has been established for a long time, is also not recorded. In future, better organised selective dismantling, modern sorting processes and research could enable previously unrecorded amounts of gypsum waste to be made available as a raw material. This, together with more complete recycling of gypsum plasterboard waste, would make it possible to increase the maximum recycling rate of 20% by 2050 (according to the Gypsum Association) even earlier.

In 2022, the amount of recorded gypsum waste was 640000 t. At the same time, 77000 t of recycled gypsum were produced, and this amount is increasing every year. The recycling rate is therefore around 12%. [3] In 2018, it was only 5% [33]. This means that 47.5% of the recovery mentioned in the 2024 monitoring report is not recycling, but the above-mentioned further use of gypsum-based construction waste.

The actual amount of recycled gypsum (RC Gypsum) used in the production of various gypsum products is still below 5%. Apart from limited availability, this is mainly due to technological reasons. The only RC gypsum available in larger quantities comes from plasterboard recycling, as only the recycling of plasterboard is established. Although it meets all requirements and is suitable for producing high-quality gypsum products, it has certain special characteristics [44]. These require adjustments to the manufacturing conditions and/or formulations when the RC gypsum content is higher. This is one of the reasons why further research is needed.

The low energy required for processing for recycling due to low hardness and low firing temperatures is a valuable property of gypsum building materials. The nearly unlimited recyclability and almost loss-free reuse of recycled gypsum in a theoretically infinite cycle makes gypsum an environmentally friendly building material (Figure 1). The recycling rate must be increased through extensive technological development, the expansion of a recycling infrastructure and the consistent implementation of selective demolition and changes to landfill guidelines [28, 33, 46, 55].

Our own extensive preliminary research has shown which manufacturing conditions are suitable for producing gypsum binders such as plaster of paris, anhydrite plaster and screed mortar. These results open up a wide range of possibilities for incorporating gypsum waste from gypsum wallboards, moulding gypsum (ceramic production), calcium sulphate flowing screeds, gypsum fibre boards or filter gypsum from production-related cleaning water into the material cycle [23]. The practical development of a gypsum lightweight plaster based on RC gypsum instead of natural gypsum has been successfully completed [20, 36, 44, 50]. It has been shown that up to 100% RC gypsum binder could be used in certain products. Problems with RC gypsum that can lead to quality losses include higher grinding fineness, significantly increased water demand for the same processing properties, loss of strength, drying cracks, the presence of residual fibres and possible accumulation of chemical additives [28, 30, 31, 36, 44, 45, 48, 58].

4 Results from gypsum building material research – Examples with promising potential for reducing environmental impact

4.1 Self-levelling screed based on plaster of paris (‘Stucco Screed’)

In 2022, 3.6 million m³ of screed was installed in Germany. Various types of cement screed accounted for the majority (53.3%) of this [56]. The current share of 1.94 million m³ of cement screed causes annual greenhouse gas emissions of around 455000 t of CO2 from cement. As part of the transition to a more sustainable economy, the aim should be to replace some of the cement screed with other building material systems with a better ecological balance. Calcium sulphate screeds (CA) are suitable for many applications, such as screeds in residential and commercial buildings. One third of the cement screed used to date could be replaced with CA. CA already accounts for 36.5% of the total screed market.

Self-levelling Calcium sulphate flow screed (CAF), which makes up the majority of CA, has many technological advantages. From a building physics perspective and with the advantage of self-levelling, it is better suited for heated screeds and has been proven to save 3% in heating costs during its life [54]. CAF is volume-stable, has high flexural strength and requires 20% less layer thickness compared to cement screed [48]. In addition, a building product made of gypsum makes an important contribution to fire protection. Calcium sulphate building materials can increase the fire resistance class of timber structures up to F180, have good thermal insulation properties in contrast to cement stone and also regulate the indoor climate.

Commercially available CAF consumes less resources and could save approx. 70% CO₂ at the component level. The primary energy necessity is at most half as high. One of the commercially available flow screed compounds requires only about 62% grey energy compared to Portland cement (PZ) with emissions of 29% of the amount of CO2 eq/t [4, 23, 40, 51].

Unlike conventional cement screeds, calcium sulphate flow screeds are jointless and can be installed with little effort. The ecological balance is significantly more favourable in terms of CO2 emissions, energy consumption and the use of FGD gypsum. A further improvement in the economic and ecological advantages can be achieved by using plaster of paris (beta hemihydrate binder) instead of the anhydrite or alpha hemihydrate binders used previously. Compared to thermally produced anhydrite binders, the production temperatures are lower and, in comparison to alpha-hemihydrate, dry heating is sufficient for binder production and further grinding is not necessary. In contrast to anhydrite-based compounds, plaster of paris achieves hydration levels of 1. In addition, hydration is complete within one day. Furthermore, a screed made of hemihydrate does not form a surface-hard sintered layer, which slows down drying to the point where it is ready for covering and requires time-consuming abrasion of the anhydrite screeds. Last but not least, plaster of paris can be walked on and covered more quickly.

In order to be flowable, plaster required too much water in the past. Various measures in a research project have reduced the water demand to such an extent that the strength requirements are now met. Despite a noticeably different compound composition compared to commercially available products, a self levelling flow screed can now also be produced with plaster in accordance with the standard.

Compared to Portland cement (PZ), plaster requires only approx. 11 to 14% of CO2 eq./t and only 30% grey energy per tonne. An increase in the market section of gypsum screed by 11% to 50% would result in savings of 64000 t of CO2, which would require 5 million trees (deciduous trees, medium age) to be planted within a year to ‘neutralise’ this amount. An increase in the market section of the entire screed and mortar market by 10% would save 3.95 million t of limestone, 774000 t of CO2 and 179 million kWh/a in Germany, as a comparable greenhouse gas reduction of more than 70% can be assumed for screed, masonry and plaster mortar [40].

4.2 Foam gypsum as a lightweight gypsum building material

Lightweight gypsum wall panels made from foamed gypsum were already being manufactured in the former GDR. Today, such building products have disappeared from the market in favour of cement-based materials. Foam gypsum is an example of a new technology within gypsum building materials. It is manufactured in two steps from gypsum binder plaster (gypsum binder, water and, if necessary, additives) and a separately produced surfactant foam (foaming agent and water) using a machine. As a result of several research projects, foam gypsum mixtures have been developed for various requirements. As horizontal filling for wooden beam ceilings (see Figures 2 and 3) or as a levelling layer, they have relevant thermal insulation and fire protection properties. Good thermal conductivity can be achieved, which is comparable to that of aerated concrete [21, 25, 43].

Another formulation is suitable for material-compatible injection of gypsum-containing masonry. It is stable when wet and has low drying requirements [21, 25, 43]. Another development is particularly suitable for vertical fillings and formwork wall components with a focus on destruction- and recycling-friendly construction (see Figures 4 - 8) [42].

In addition, foam gypsum can be used as a filler in textile envelope structures for the production of lightweight composite elements for the design of walls and ceilings, as well as for mobile partition walls. In the related GIPSTEX project [19], good acoustic performance was achieved with customisable design and suitability for use in existing buildings.

In parallel with the application-specific foam plaster formulations, machine types were developed that can be optimally used on construction sites or in manufacturing, depending on the application.

A current research project is working on the development of a foamed lightweight plaster. The focus here is on developing a machine that combines the functions of a conventional plastering machine with foam gypsum machine technology. The aim is to produce a lightweight gypsum plaster that does not require the usual addition of lightweight aggregates (such as perlite or polystyrene beads).

4.3 Lightweight gypsum plaster based on RC gypsum

As a result of the EcoStuc research project, a lightweight gypsum plaster was developed in a practical manner, in which up to 100 % recycled gypsum can be used as a raw material. It can be processed and applied in accordance with the usual technical rules and standards. A detailed article appeared in ZKG 07/2024 [44]. (see Figure 11)

With regard to the environmental impact compared to a commercially available light gypsum plaster made from natural gypsum, life cycle assessment considerations yielded the following results. For the calculations of the two raw materials, natural gypsum and RC gypsum, life cycle phases A1 to A3 (manufacturing phase according to Table 1 or cradle to gate) were taken into account, as well as whether or not the material is landfilled at the end of its life. For the primary raw material natural gypsum, landfill is taken into account in accordance with the linear pathway. For the recycled gypsum no landfill is taken into account in order to reflect the fact that it has already completed one life cycle. Under these conditions, the currently sometimes long transport distances for the CO2 equivalent (= GWP = CO2 footprint) of RC gypsum. This is the sum of the transport distance of the gypsum plasterboard waste to the recycling centre and the transport from the recycling centre to the gypsum plant. In contrast, gypsum quarries are often located close to the gypsum processing plant (assumption: 5 km). If RC gypsum is transported no more than 150 km in total, it generates a CO2 footprint that is comparable to that of natural gypsum (approx. 30 to 35 kg CO2 eq./t of gypsum). However, due to the limited number of gypsum recycling sites in Germany, transport distances can be significantly longer. They can more than triple the GWP of RC gypsum compared to natural gypsum. Transport distances will decrease as more recycling plants are commissioned in Germany.

If 1 tonne of plaster is considered as dry mortar for the cradle-to-gate life cycle phases, the dry mortar made from RC gypsum causes less than half the CO2 emissions of an average lime-cement plaster, even under the most unfavourable assumptions. Depending on the transport route, the dry mortar mixture with 100% RC gypsum causes 120 or 166 kg CO2 eq./t, while a lime-cement lightweight plaster generates 353 kg CO2 eq./t.

5 Summary

The potential of gypsum building materials for decarbonising the building materials industry is being investigated against the backdrop of increasing regulatory requirements, limited availability of raw materials and the need for closed material cycles. The starting point is the environmental impact of the construction industry, which contributes significantly to raw material consumption, waste accumulation and national greenhouse gas emissions in Germany. Gypsum is a non-carbonate building material. It is produced at considerably lower temperatures and offers ecological advantages over cement- and lime-based materials due to its complete recyclability. The second part of the article presents current research results on innovative gypsum products, including ‘stucco screeds’ with reduced energy and CO₂ requirements, foam gypsum with thermal insulation and fire protection properties, and lightweight gypsum plasters based on up to 100% recycled gypsum. The presented developments illustrate that the targeted use and further development of gypsum building materials can make an important contribution to resource efficiency and emission reduction in the construction industry.

6 Acknowledgements

All images, illustrations and tables: Materials Research and Testing Institute Weimar (MFPA)

Many thanks to all project partners for their trusting and fruitful collaboration.

and Properties of Secondary Gypsum Binder. Recycling 7/30. https://doi.org/10.3390/recycling7030030

uploads/1311_DIW-Econ_Gipsindustrie-im-Suedharz_update-2019_v.4.0.pdf - Abruf 14.08.2025

![2 Flowable foam gypsum for filling wooden beam ceilings (practical test as part of the SULFOAM research project [21])](/uploads/images/2025/11703_w300_h200_x600_y450_Figure_2-78f556bd77f5b6ad.jpeg)

![3 Filled wooden beam ceilings with foamed gypsum plaster (practical test as part of the SULFOAM research project [21])](/uploads/images/2025/11704_w300_h200_x600_y450_Figure_3-bbe4ff3fd7b2bdc7.jpeg)

![4 Filling a double-shell demonstrator wall with foam gypsum (practical test Project SULFOAM [21])](/uploads/images/2025/11705_w300_h200_x600_y800_Figure_4-837f8a7d993aacb4.jpeg)

![7 Formwork-free compartment filled with foam gypsum (demonstrator timber framework) with plaster base (practical test Project Leichtgips [42])](/uploads/images/2025/11708_w300_h200_x600_y450_Figure_7-ed98a9bc92505c5d.jpeg)

![10 Software-generated visualisation of a possible arrangement of GIPSTEX lightweight elements on the ceiling when converting industrial buildings [19]](/uploads/images/2025/11711_w300_h200_x600_y450_Figure_10-3285b0fb8f8ea326.jpeg)

![11 Practical test in the EcoStuc project, machine-processable lightweight plaster made from 100% RC gypsum [41, 44]](/uploads/images/2025/11712_w300_h200_x600_y800_Figure_11-8f88093d8a6ca8e4.jpeg)