Better decisions in cement strength prediction with artificial intelligence

It has been said that “software ate the world, now AI is eating software” [1]. The growth of artificial intelligence (AI) is relentless [2] – the process-automation sector being no exception. More and more analytics applications are processing data from online sensors and laboratories, making processes more efficient and increasing process autonomy. The last decade has seen a trend towards such applications being deployed in the cloud. However, in many cases, it is not practical to transfer huge masses of data to the cloud. Hence the emergence of edge analytics.

In edge analytics, processing tasks are executed in the proximity of where the data is generated (eg., on site) in order to enable faster response times [3-4]. Example applications in process automation include asset-condition monitoring, process-function monitoring, and anomaly detection, with areas of deployment extending to smart cities and smart transportation [5]; edge computing is rapidly becoming a leading digital technology.

Edge computing and edge analytics provide many benefits:

The physical proximity to the devices makes it easier to achieve low latency and high bandwidth. This means higher volumes of data can be processed with faster response times

Processing data on the edge reduces data traffic to the cloud, as only filtered and/or aggregated information needs to be transmitted

On the edge, it is easier to protect applications and data with respect to cyber security, as data is processed locally, before releasing parts of it to the cloud via a secure edge gateway, ie. the attack surface is smaller

Edge nodes can operate even when cloud services are unavailable due to network or cloud failures, or for mobile equipment like trucks, which may have intermittent internet connection. Data privacy considerations may also favor this solution. Edge processing therefore improves availability and reliability for key services

Legacy devices that cannot establish their own cloud connections can be integrated into edge-based system architectures

Edge resources are usually less expensive than cloud resources

Edge computing complements cloud computing as data- and resource-intensive tasks (such as training of machine learning models) can be moved to the cloud, while the actual prediction can be deployed on the edge. All in all, the emergence of edge analytics introduces many possibilities for industrial analytics.

The ABB Ability™ Genix Industrial Analytics and AI Suite enables vast potential for edge analytics. This article presents a research-level proof of concept, illustrated by the use case of cement strength prediction.

Example: Cement strength prediction

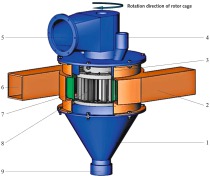

In the cement-making process, the quality of cement is influenced by many factors (Figure 1). Variability in raw feed and fuel types means that cement production is rarely constant. Continuous changes in plant operating points are needed to counter this variability, guided by online and lab measurements. A particularly important quality is “28-day cement strength.” If cement strength is too low, it cannot be sold, or requires blending with a higher-grade of cement. Conversely, cement strength that is too high comes at the cost of either reduced yield or excessive additives (which means excessive costs). Traditionally, there is a delay of 28 days until it is possible to test cement strength. By then it is too late to make corrections in the process. This means plants often over-deliver on the cement strength specification at reduced profit potential.

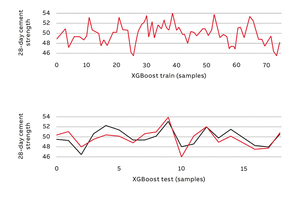

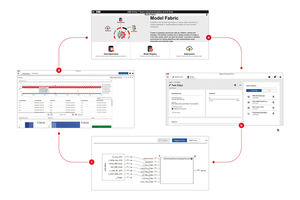

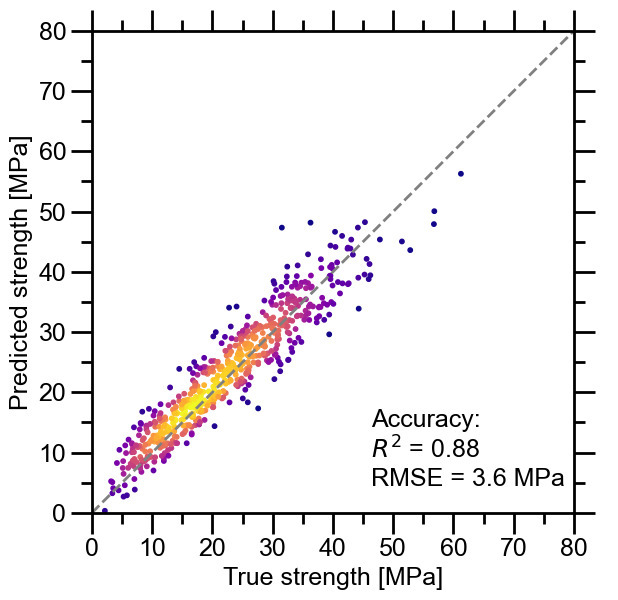

Having a way to predict the 28-day cement strength during production, preferably many times a day, could enable plants to respond in a much more timely manner. ABB tackled this challenge using machine learning functions within the ABB Ability Genix Industrial Analytics and AI Suite. Models were built in ABB Ability Genix using its Model Fabric component to map sampled data and predict 28-day cement strength (Figure 2). Multiple proposed models were reviewed in Genix Model Fabric for accuracy and robustness before a final model was selected (Figure 3). This model was then deployed on the edge to predict 28-day strength based on production data provided every 2-3 hours.

The ongoing accuracy of the on-premise model will be monitored before action is potentially transferred to another ABB technology: the ABB Ability™ Expert Optimizer. This technology automatically makes corrective changes to the production process and will aim to reduce variability and achieve a more constant 28-day cement strength closer to target. Expected benefits of achieving this target are increased yield with reduced additive consumption costs.

ABB Ability Genix Industrial Analytics and AI Suite

The ABB Ability Genix Industrial Analytics and AI Suite [6-7], is a scalable, advanced analytics platform with pre-built, easy-to-use applications and services. ABB Ability Genix is designed to improve customer decision-making by predicting and optimizing asset, plant, and enterprise performance. Genix assists customers in designing and applying analytics. It unlocks the value of data by combining ABB’s deep industrial domain expertise with digital technology and capabilities.

ABB Ability™ Edgenius Operations Data Manager

Edgenius [8] is ABB’s edge component for industrial software applications and can be applied as a standalone operational data collection and computation manager, or embedded in the Genix Suite in order to incorporate operational data into analytics in a robust manner. It includes multiple modules to gather data from operational technology, such as distributed control systems and instruments, or via OPC protocols. With Edgenius’ streaming calculation engine, real-time data can be made available with minimal latency. Easy deployment, configuration and monitoring of edge nodes and applications across the entire enterprise is enabled via the Edgenius Management Portal.

Edgenius fully addresses NAMUR Open Architecture (NOA) requirements [9]. Following the intent of NOA, Edgenius leaves the Core Process Control (CPC) of a process plant unchanged and secure, while providing additional IoT functionality in the so-called Monitoring and Optimization domain (M+O). The use of different security zones ensures that the security of the process automation system is not compromised even though data and information is flowing from the process to the M+O modules. Furthermore, separation of the lifecycles of CPC and M+O modules is achieved, leading to faster updates and greater speed of innovation.

Integrated Edge Analytics Workflow

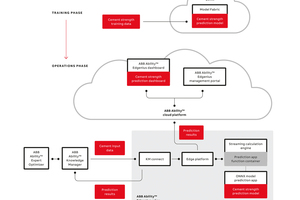

The integrated workflow for an edge analytics solution implementing the above cement-strength prediction is shown in Figure 4. The view distinguishes between the training phase, where the AI/ML model is created and trained; and the operations phase, where the model is used to predict results during production.

The Model Fabric component allows any non-expert data scientist to explore and pre-process the data in order to create a machine learning pipeline. The cement strength prediction model has been automatically trained and optimized using an AutoML approach in the following modules of Model Fabric:

Data exploration: The prebuilt data exploration capability of Model Fabric helps the quick and easy “data understanding” for a business or a data scientist

Data preprocessing: Data is preprocessed based on proven data-science methods and techniques before it goes to the model building stage

Model building: The preprocessed data is split into training and testing data sets and models are built with multiple proven learning algorithms. Model fabric takes care of appropriate “validation” as well as fine tuning of parameters while building the models. Once models are built it provides evaluation metrics along with plots and suggestions concerning the choice of models

Model registry and deployment: Model fabric supports the complete life cycle of AI/ML model. Once the model is built, this module provides hassle-free model registry and deployment

The resulting model is used in the operations phase. It is deployed from Genix Model Fabric as part of an ONNX model prediction app, which uses the ONNX [10] inference engine (ONNX=Open Neural Network Exchange, an open standard for Machine Learning model exchange). ONNX provides interfaces to many available frameworks (eg, TensorFlow and ScikitLearn) without regard to detailed model implementation. The ONNX model prediction app is deployed in Edgenius as a Docker [11] container with a RESTful Application Programming Interface. This means that it can be implemented in any programming language that provides the functionality to create an HTTP endpoint.

For retrieving production data, a connect module, KM Connect, connects to the ABB Ability Knowledge Manager (KM) system and feeds the cement input values coming from KM into the edge system. For further use cases, other connect modules can be used, such as Distributed Control System Connect to connect to an ABB Ability 800xA DCS, or OPC UA Connect to interface to an OPC UA server. To bring the data and the AI/ML model together, the Edgenius Streaming Calculation Engine maps data streams to the inputs of the prediction function and triggers the function periodically or at defined events.

Screenshots of the described workflow are shown in Figure 5, which starts at (a) with Genix Model Fabric. (b) is a view of an edge in the Edgenius Management Portal. The left part of this screen shows general information, while the installed applications are displayed on the right. (c) shows how the inputs of the KM Connect module are mapped to the deployed cement strength prediction function within the Edgenius’ Streaming Calculation Engineering Tool. The predicted results, ie, the expected cement strength values, are transferred back to the KM and potentially to Expert Optimizer in order to apply corrective changes. The results can also be visualized using Edgenius dashboards (d).

This workflow is a loop that can be adjusted over time: ie, whenever the deployed AI/ML model is detected to not be optimal anymore (e.g., because environmental conditions changed), in such situations the model can be retrained and redeployed.

An applicable solution

The proof of concept presented in this article of using the division between cloud and edge, is applicable to all types of inferential decision making across all industries. It is presently still at a research level, but ABB hopes to offer it to customers soon. The goal will be to make it easy to build, deploy and maintain models.

In the future, it is to be expected that edge analytics applications will become even more advanced and complex. Instead of focusing on one edge or on a few edges, the development can be expected to evolve toward hierarchical edge networks and edge meshes. This opens the door to powerful distributed analytics techniques.