Prediction of cut size for pneumatic classification based on a back propagation (BP) neural network

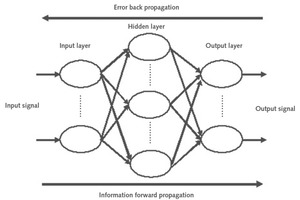

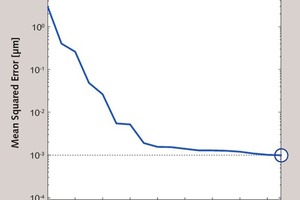

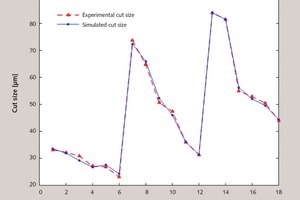

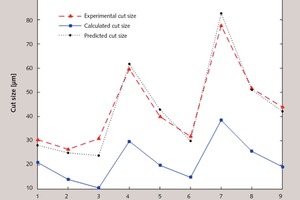

A new method is provided for predicting the cut size of a turbo air classifier using a BP neural network and a three layer BP neural network prediction model for cut size based on the training samples has been established. The MATLAB neural network toolbox can be used conveniently to calculate the prediction model. Verification results from the testing samples indicate that the predicted cut size using this BP neural network model is closer to the experimental cut size than the calculated cut size using a theoretical formula from other findings.

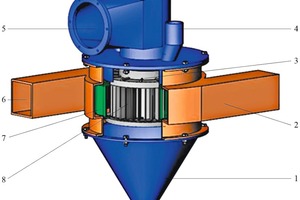

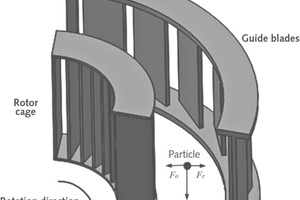

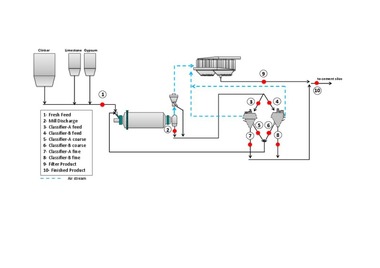

Cut size is one of the most important classification performance indices for powder classification equipment. To a certain extent it reflects the fineness of the product. For the same structure the cut size is determined mainly by such operating parameters as air inlet velocity, feed rate, and rotary speed of the rotor cage. A three layer (BP) neural network prediction model for calculating the cut size was introduced with the aim of predicting the cut size for pneumatic classification accurately using a turbo air classifier as an example. The calcium carbonate classification experiments were...