CO2-reduced building construction thanks to new KS*ReCO sand-lime bricks

On its path to climate neutrality, E. Bayer Baustoffwerke GmbH + Co. KG has developed KS*ReCO sand-lime bricks that generate around 40% less CO₂ than the conventionally manufactured version of the wall building material. The reduced emissions result from the targeted use of regional raw materials and recycled building materials, as well as an optimized production process.

While the conventional recipe for masonry bricks consists of the natural raw materials lime, sand, and water, KS*ReCo is the first to use recycled concrete sand in its production. It replaces both part of the sand and the lime, which causes most of the CO2 emissions during production. “In addition, we have chosen stone compressive strength class 12,” explains Managing Director Jörg Bayer. “This also saves energy during the pressing process without compromising on structural and technical qualities.”

Compliant with standards and climate-friendly

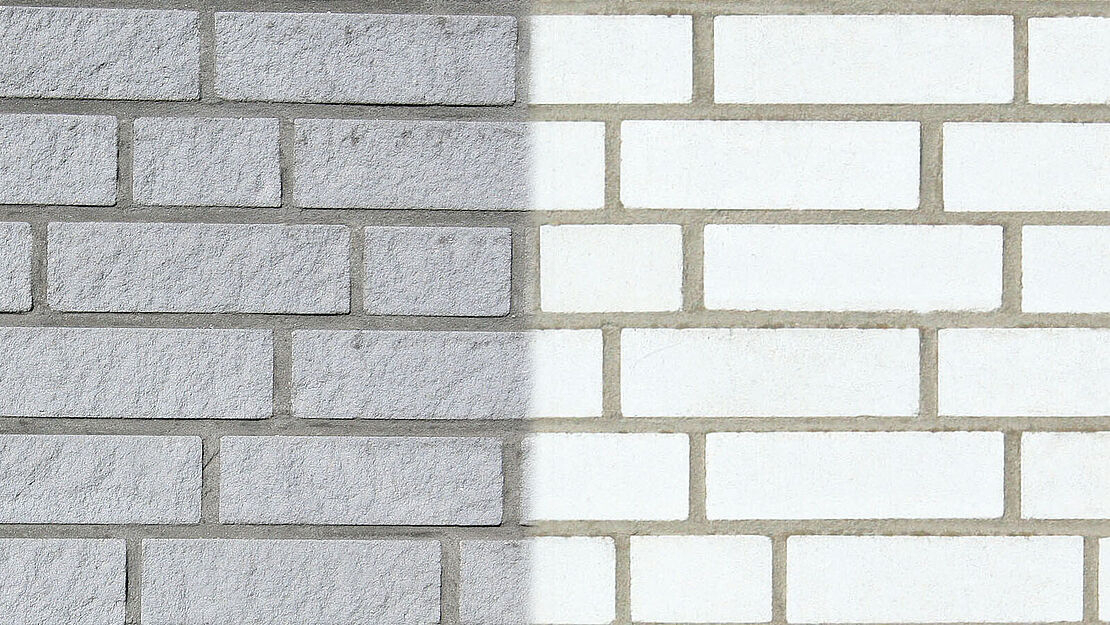

The result is a sand-lime brick with a significantly reduced GWP (global warming potential) of 75.72 kg CO2/t. According to the environmental product declaration, the average GWP is 126 kg CO2/t. In order to meet common protection goals as well as requirements for load-bearing capacity and durability, the white wall-forming material is certified in accordance with the applicable DIN EN 771-2 and DIN SPEC 19458 standards. At the same time, it addresses the rising expectations for environmentally friendly construction. The consistent use of regionally available materials also keeps transport distances short. In this way, the building material actively contributes to reducing CO₂ emissions in the construction sector and thus to achieving climate targets. “With KS*ReCO, we are demonstrating that resource-saving, ecologically responsible construction and the proven KS construction method can be combined well,” says Managing Director Jörg Bayer.

Proven construction method for economical housing construction

The newly developed masonry block is now available in the form of large-format plan elements of the KS-Plus construction system with lengths of 1000 mm, thicknesses of 175 and 240 mm, and heights of 498 and 623 mm. This makes it particularly suitable for the efficient construction of load-bearing walls in multi-story residential buildings. In addition, E. Bayer Baustoffwerke GmbH + Co. KG is working on a further product line for non-load-bearing walls, which will result in further CO2 savings.