Concentrated solar cement kiln

(22) 19.02.2021

(43) 25.08.2022

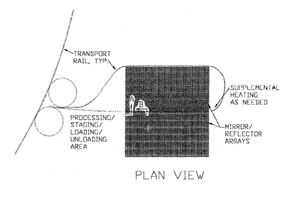

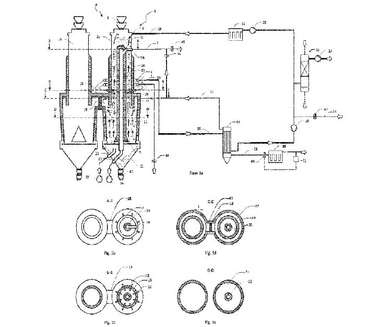

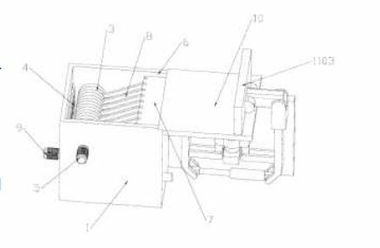

(57) The subject invention combines two long-established technologies – cement kilning and solar radiation concentra-

tion – to create a new process to kiln cements that will significantly reduce the non-renewable energy consump-

tion and pollution and CO2 generation of current cement kilning methods. The process entails using focused solar radiation to heat closed containers containing cement raw materials to kiln the raw materials to produce cement, including Portland cement.

(71) Peter G Newton, Boise, ID (US)