Control method for energy-saving fluidization furnace for calcining gypsum with ultralow-pressure steam

(22) 27.02.2024

(43) 23.07.2025

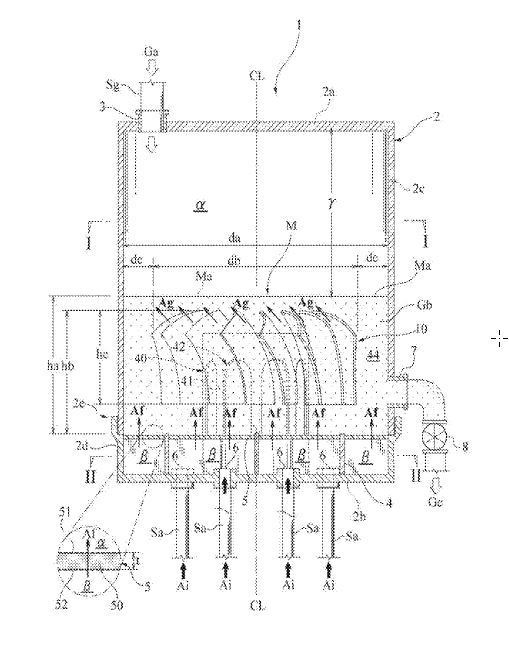

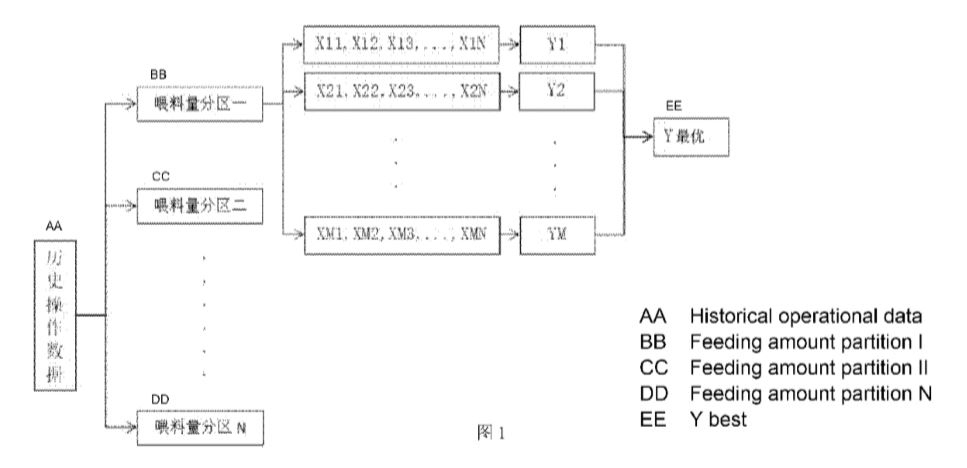

(57) The present disclosure relates to the field of fluidized-bed furnace technology and discloses a control method for an energy-saving ultra-low pressure steam calcined gypsum fluidized-bed furnace. The control method includes: Step S1: switching on a fluidized-bed furnace steam inlet valve to preheat a fluidized-bed furnace system; Step S2: turning on a dust collecting fan, a dust collector, and a Roots blower; Step S3: turning on a raw material feeding system; and Step S4: feeding a raw material into the furnace, controlling the system to first enter a manual operation system, where a height of feed layer also gradually increases as feeding amount gradually increases, and gradually increasing a furnace bottom pressure from ordinary pressure to about 20 kPa. A temperature control system may be switched into automatic control after material temperature inside the furnace is stabilized. Steam temperature is adjusted through a bypass cold water valve, such that the steam temperature at a control position is within ±2°C of saturated steam temperature, to ensure sufficient calcination time of the material and guarantee quality of the gypsum.

(71) CNBM Design & Research Institute Co., Ltd. Hangzhou, Zhejiang 310022 (CN)