Eco-friendly mortar composition employing blast furnace slag fine aggregates and ready-mixed concrete recovered water

(22) 22.03.2021

(43) 28.07.2022

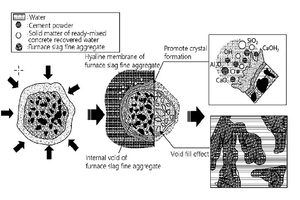

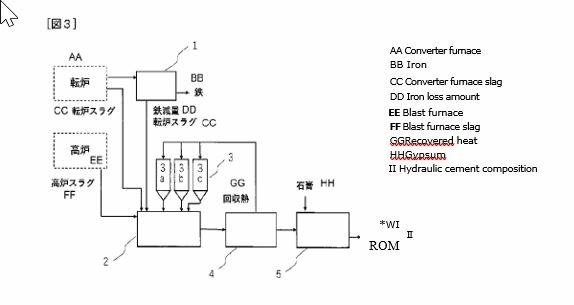

(57) The present invention relates to an eco-friendly mortar composition, which leads to an increase in recycling rate of recovered water, a by-product in the ready-mixed concrete industry, and employs blast furnace slag fine aggregates generated as an industrial by-product after the extraction of metals from ore during a steelmaking procedure and ready-mixed concrete recovered water generated during a ready-mixed concrete

producing procedure. More specifically, the present invention relates to a method in which blast furnace slag fine aggregates

are incorporated at an increased ratio into mortar employing ordinary Portland cement and natural pit sad fine aggregates, thereby promoting the fluidity,

strength, and durability performance of the mortar. The present invention provides an eco-friendly mortar composition

employing blast furnace slag fine aggre-gates and ready-mixed concrete recovered

water, the mortar composition comprising

330-360 parts by weight of cement, 80-320

parts by weight of fine aggregates, and 160-180 parts by weight of combined water, wherein: the fine aggregates are composed of 60-90 vol% of natural fine

aggregates and 10-40 vol% of blast

furnace slag fine aggregates; the combined

water contains 5.0-10.0 wt% of solids

obtained from ready-mixed concrete

re-covered water. the solids promoting the reactivity of the blast furnace slag fine aggregates.

(71) Wonkwang University Center for Industry-Academy Cooperation,

Jeollabuk-do (KR)