Green Challenge in the Lime Industry: Knoblinger sets standards for 100% biogenic fuels

The lime industry is under pressure to decarbonize like hardly any other sector. Fossil fuels drive emissions and costs upwards – and call for bold alternatives. At Albert Knoblinger GmbH & Co. KG, based in Ried im Innkreis/Austria, we have taken on this challenge and, together with Köhler Kalk in Germany, implemented a pioneering plant that is making history: For the first time in Germany, lime is being produced using 100% biogenic fuel. “This project shows that the energy transition in the lime industry is not a vision of the future – it is happening now. And we are proud to play the key technological role in this transformation,” emphasizes Division Manager René Brückl, MSc.

Fossil dead end – new ways forward

The challenges of the industry are clearly defined:

High emissions from fossil fuels and rising ETS costs,

Price volatility and geopolitical dependencies,

Growing customer demand for sustainable products

Our response at Knoblinger: the consistent development of plants for renewable, regional and secure fuel solutions. Biomass – particularly in the form of pelletized and ground wood biomass – has proven to be a stable, low-emission and standardized fuel.

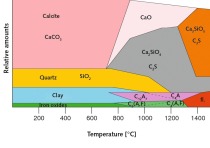

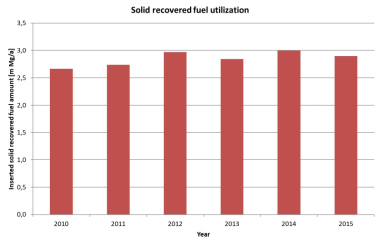

Biomass as the key to decarbonization

The EULA Carbon Reduction Roadmap clearly shows: biomass will remain the most important driver of emission reductions in the lime industry at least until 2030. Our experience confirms this – biomass pellets are today the most mature, available and economically viable solution.

Their advantages:

High energy density and defined calorific value,

Low dust emissions during handling,

Controlled moisture and storage stability, - Standardization and maximum safety in application

“At Knoblinger, we see biomass not only as a bridging technology but as an essential building block for the future of the lime industry,” emphasizes Dipl.-Ing. (FH) Franz Bachinger, Technical Sales.

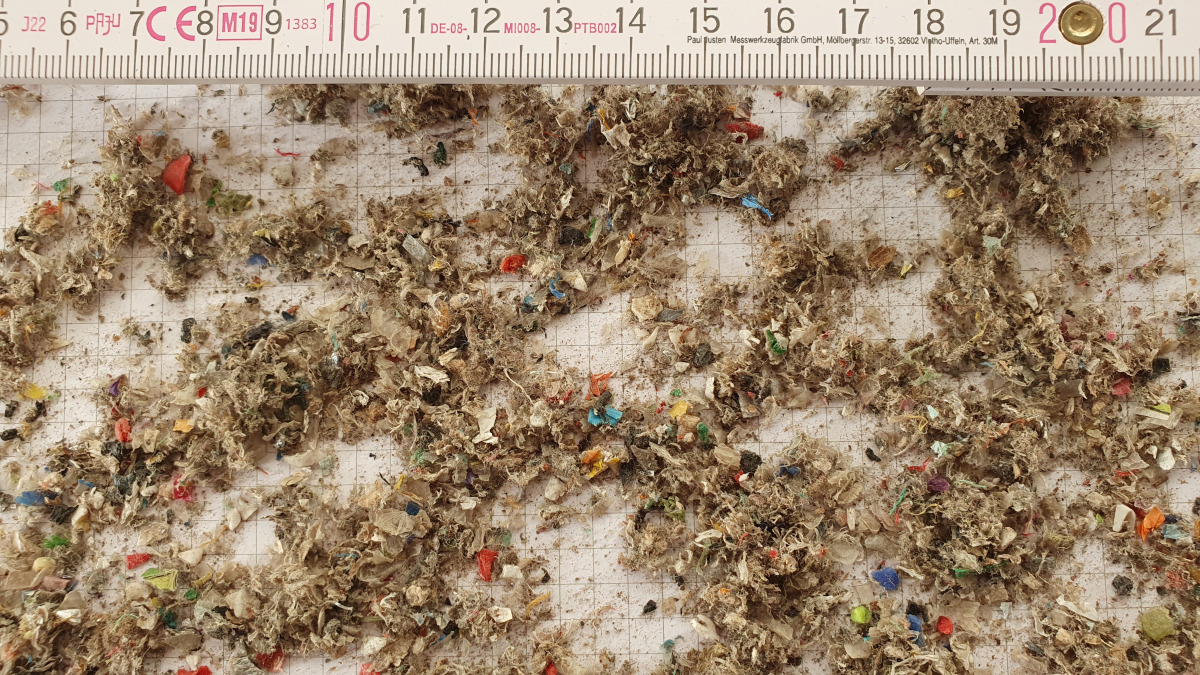

The Köhler Kalk project: 100% switch to wood dust

With Köhler Kalk, a lime plant in Germany was converted entirely to biogenic fuel for the first time in 2024/25. We at Knoblinger supplied the complete process chain – from reception to silos and material handling to safe dosing into the kiln:

1. Pellet reception and quality control: Flexible stations for walking floor and tipper trailers with capacities of up to 60 t/h

2. Silos and material handling: Low-emission storage with precise discharge and dosing technology

3. Grinding and pulverization: Energy- and cost-efficient comminution to < 3.0 mm (possible down to < 1.0 mm), grinding capacity 6 t/h, with high plant availability

4. Safety systems: Temperature monitoring, dust extraction, ATEX explosion protection

5. Fuel dosing: Fully automatic conveying and dosing systems for maximum operational reliability

The result: lime production using 100% wood dust – without any fossil additives.

Knoblinger as a big player

Knoblinger has been delivering customized bulk material technology for over 60 years. Today, we are the number one supplier of wood pellet production plants in Europe and a leading partner for alternative fuel systems in the lime and cement industry. Our figures speak for themselves:

20% market share of installed wood pellet plants in the EU,

80% export share to more than 25 countries,

Projects delivered in Europe, Asia, North and South America

“Our strength lies in combining tradition with innovation. We provide not just technology but true partnerships and operational reliability – for our customers and for climate protection,” explains Managing Director Dipl.-Ing. (FH) Jürgen Zuser.

Results and impact

The conversion at Köhler Kalk delivered immediate measurable benefits:

CO₂ reduction of up to 100% in fuel use,

Significant reduction of ETS costs,

Greater independence through regional supply chains,

Market differentiation through sustainable lime products

It is clear: with Knoblinger technology, the complete substitution of fossil fuels in the lime industry is not only possible – it is already reality.

Looking ahead

While hydrogen or electrification are being discussed as long-term options, biomass will remain the central pillar of decarbonization until at least 2030. At Knoblinger, we are already working on further innovations: - Integration of torrefaction and biochar into the fuel mix, - Automated blending systems for various biogenic raw materials.

“Our aim is to actively shape the energy transition – with intelligent technology, sustainable solutions and handshake quality,” adds Jürgen Zuser.

Conclusion

The project at Köhler Kalk marks a milestone for the industry. As a family-owned company from Ried im Innkreis, we are proud to have enabled the first 100% biogenic lime production in Germany with our technology.

Knoblinger is more than a plant manufacturer: we are an industry partner, a driver of innovation and a reliable guarantor of operational safety. Or as we like to say: “We don’t just deliver plants – we deliver trust, sustainability and the future.”