Physical-mechanical properties and hydration microstructure of slag powder/cement system with different nanoparticles

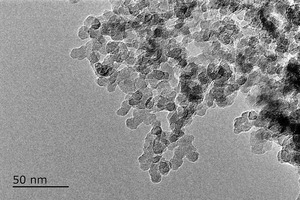

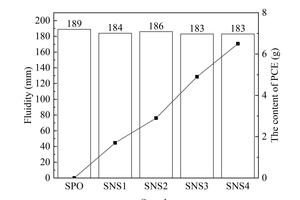

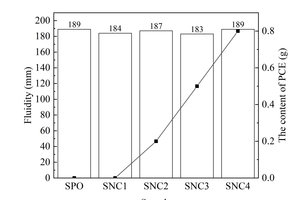

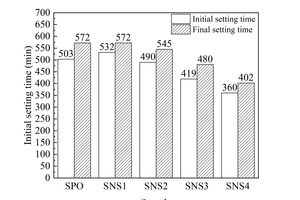

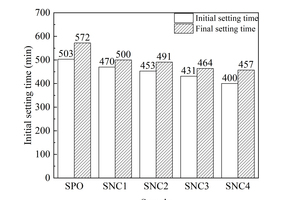

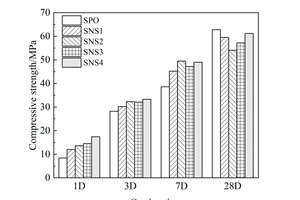

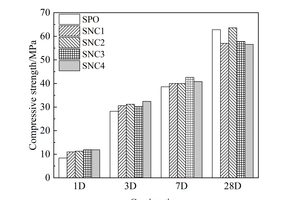

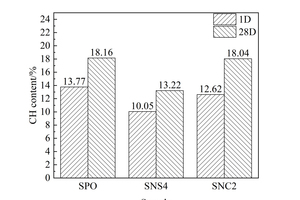

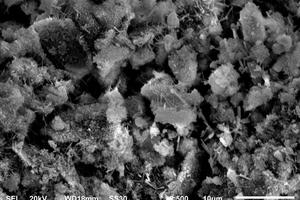

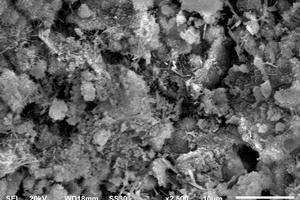

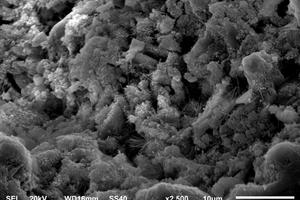

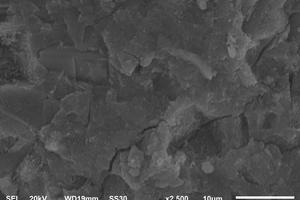

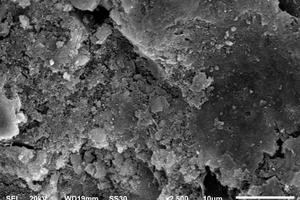

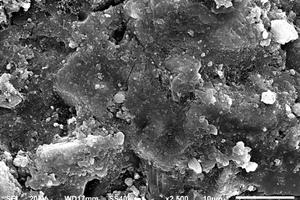

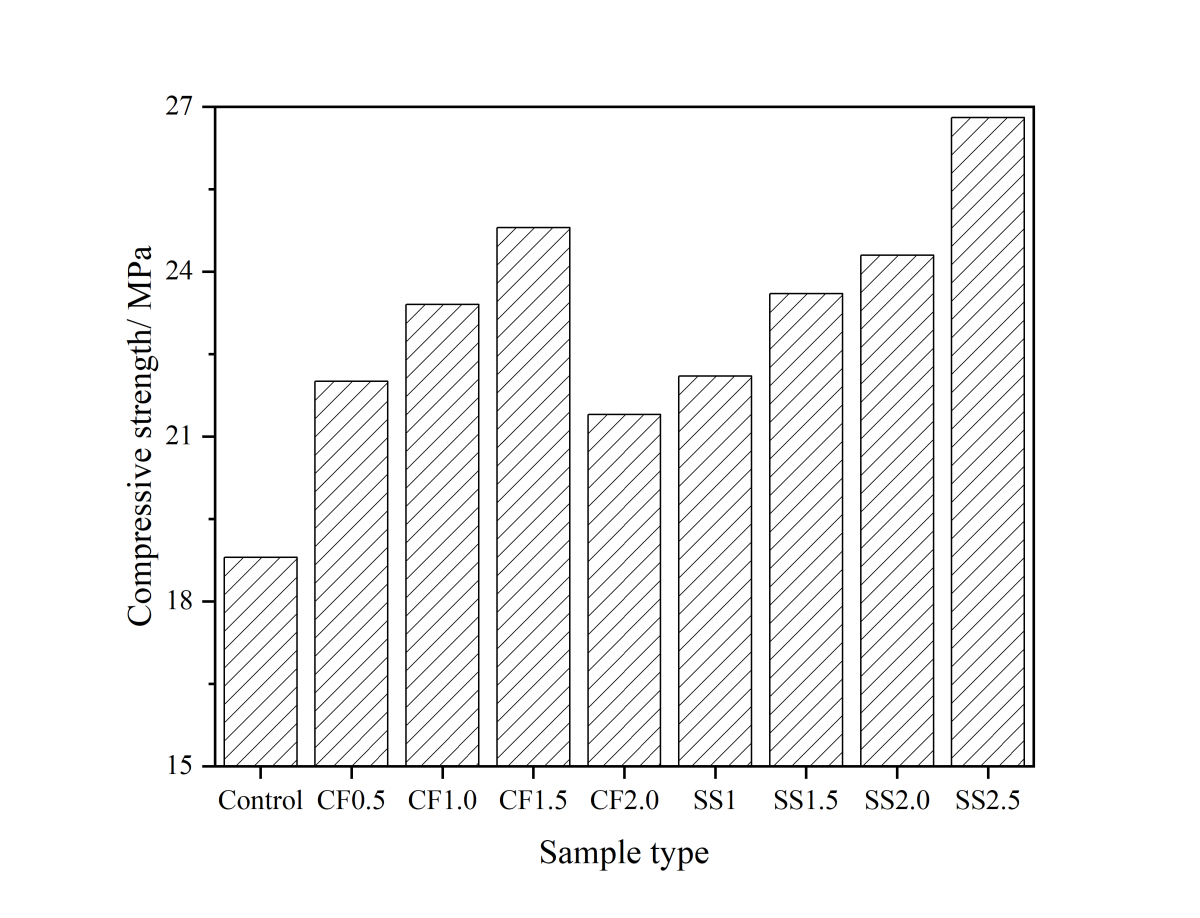

Nano-silica (NS) and self-made nano-calcium silicate hydrate (NC) were mixed into the slag powder/cement system, and the effects of the two on the physical-mechanical properties and hydration microstructure of the slag powder/cement system were compared. Results show that the incorporation of NS and NC can shorten the setting time, promote the early hydration of the composite binders and greatly improve the early strength of the matrix. However, since the activity of NS is higher than that of NC, the improvement effect of NS on 1 d, 3 d and 7 d strength of the slag powder/cement system is higher than that of NC. At 28 d, both NS and NC had no significant effect on the matrix strength. The pozzolanic effect of NS and the nucleation effect of NC can provide more seed crystals for the hydration of cementitious materials, and the generated hydration products can fill in the pores between different size particles and improve the early microstructure, which in turn increases the early strength of the slag powder/cement system.

1 Introduction

Cement is the most used cementitious material in engineering construction in China. Its hardened paste is loose and porous, and the erosive substances can easily enter through the pores and cause deterioration of the matrix. Some studies have shown that adding a certain amount of mineral admixtures into cement can effectively refine the pore structure [1], increase the compactness [2] and improve the durability of cement-based materials [3, 4]. However, the adding of mineral additives often causes a reduction in the early strength of cement-based materials [5], which is...