Practice of energy efficiency improvement for the pyro system of the 10000 t/d production line

Aiming at the technical bottleneck of energy efficiency improvement of the CUCC (Xuzhou) 10000 t/d production line, a solution of pollution reduction and carbon reduction of the pyro system was proposed. The five-stage preheater was changed to a six-stage preheater for the first time in the Chinese cement industry. The calciner volume was expanded and self-denitrification technology was adopted to improve the efficiency of the main combustion area, the speed of the rotary kiln was accelerated, and the cooler was changed to the fourth-generation cooler with middle roller crusher. After the modification, the outlet temperature of the preheater is reduced by 83 °C, the fuel consumption of clinker is reduced by about 98 kcal/kg.cl, the fuel consumption per unit product of clinker reaches and is lower than the level 1 index of the GB 16780-2021 standard by about 4%, 43000 t of standard coal is saved every year, and the annual carbon dioxide emission is reduced by 108000 t.

Meanwhile, the emission reduction technology of the self-denitrification source is applied in the existing preheater tower. The NOx emission is lower than 25 mg/Nm3 required by the local environmental protection department, the ammonia consumption is reduced by 10000 t/a. It provides a technology demonstration for the new upgrading of cement manufacturing under the double carbon strategy background, double control of energy consumption and ultra-low emission targets.

1 Introduction

The 10000 t/d clinker production line is the benchmark for large-scale cement production technology, and has been attracting extensive attention all over the world [1, 2]. The CUCC (Xuzhou) 10000 t/d production line was put into operation in 2004. Its pyro system is mainly equipped with Polysius five-stage suspension preheater, MSC online calciner, Polysius three-support rotary kiln, CP cooler, etc. The production line has been in operation for nearly 20 years, and its fuel consumption, electricity consumption and emission have been unable to conform to policy requirements of dual control of energy consumption [3] under the national “double carbon (carbon peaking, carbon neutrality)” strategy at the current stage. In order to achieve sustainable development of the production line, the technological upgrading of energy conservation, carbon reduction and ultra-low emissions have been carried out.

Improving the energy efficiency of the production lines is one of the important ways to reduce carbon emissions in the cement industry [4], for more than 1500 existing domestic cement production lines in particular [5]. The improvement of energy efficiency is more suitable for China’s current conditions, and also effectively promotes the application of new technologies such as alternative fuels for carbon emissions reduction [6], with vast potential for future development. Aiming at the optimization and improvement goal of the CUCC (Xuzhou) clinker production line, the company proposed two technical proposals on the basis of the research results of green and low-carbon technology at the current stage, namely, upgrading the five-stage preheater to six-stage and upgrading the five-stage preheater to seven-stage. The pollution and carbon reduction technological route of upgrading the five-stage preheater to six-stage preheater was finalized.

2 Conditions before upgrading

2.1 Pyro system

The rotary kiln is supplied by Polysius with specifications of Φ 6.0/6.4 m × 90 m, design speed of 3.5 r/min, and actual running speed of 3.0 r/min; Polysius five-stage double string preheater, Φ 7.64 m × 50 m MSC calciner with volume of 3400 m3, and CP cooler. The tertiary air duct has diameter of Φ 3.35 m. The raw mill includes two sets of ATOX 50 roller mills, while coal mill includes two sets of MPF 2217 roller mills.

2.2 Raw materials and fuels

The raw materials of this production line are composed of limestone, coal gangue, iron tailings and sandstone. The limestone comes from its own mine. It is proposed to purchase a new mine. The surface of the new mine contains siliceous impurities such as clay. Both existing and new mines have low grade of limestone, with high content of magnesium and alkali, resulting in clinker 3 d strength of 31 MPa and 28 d strength of 56 MPa. Fineness of pulverized coal: 10% residue on 80 μm sieve, fineness of raw material: 20%-22% residue on 80 μm sieve, 2% residue on 200 μm sieve, with decomposition rate at the kiln inlet of more than 95%. Refer to Table 1 for the chemical composition, mineral composition and values of clinker and Table 2 for industrial analysis of pulverized coal.

2.3 Performance before upgrading

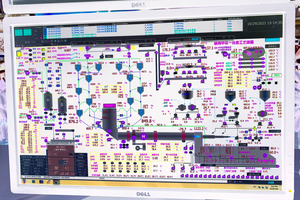

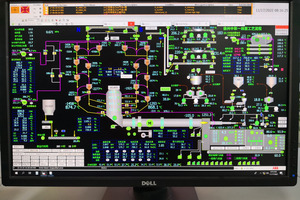

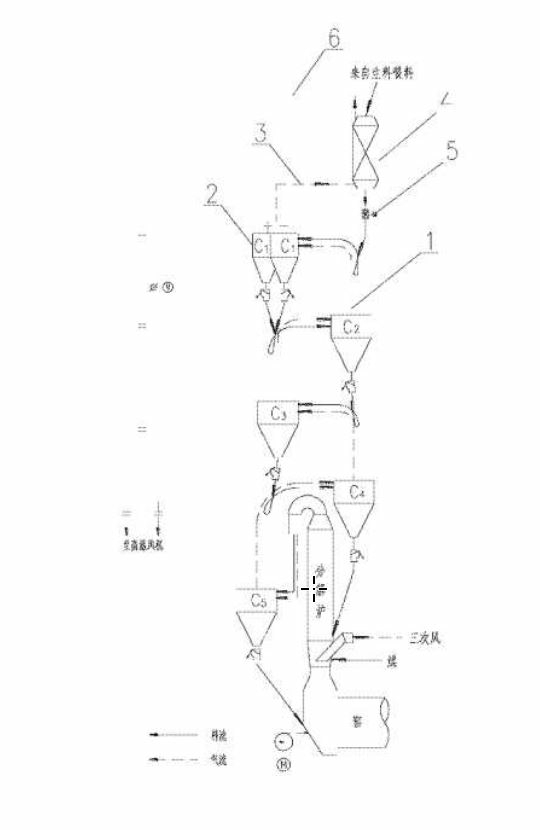

The fuel consumption of clinker production was 749-756 kcal/kg.cl, electricity consumption of clinker was 56 kW·h/t.cl, clinker temperature of cooler outlet was >200 °C, the outlet temperature of preheater C5 was 340 °C-350 °C, the pressure drop of preheater was -5000 - -5200 Pa, with high outlet temperature of preheater. The outlet temperature of last-stage C1 cyclone was 790 °C (the on-site temperature measurement point had high position, which also had certain impact on the outlet temperature), the outlet pressure was -1700 Pa, the temperature of discharge pipe was 860 °C, and there was a certain degree of pulverized coal post-combustion. The temperature of tertiary air was 850 °C, the temperature of secondary air was 1120-1190 °C, and the temperature of waste gas in the cooler bag house was 131 °C. Based on the analysis of preheater temperature, pressure distribution, secondary and tertiary air temperature and other parameters, we found the preheater had low thermal efficiency, heat recovery rate of the cooler was at a low level compared with the production lines put into operation in recent years, it has high overall coal and electricity consumption, and low thermal efficiency, approximately –55%. The waste heat power generation boiler had low efficiency, and the power generation capacity was approximately 31 kW·h/t.cl. The energy consumption per unit product of clinker was 770 kcal/kg.cl, which was higher than the Level 2 index of 749 kcal/kg.cl in GB 16780-2021 The Norm of Energy Consumption per Unit Product of Cement [3]. Refer to Figure 1 for the central control picture of pyro system before upgrading.

2.4 Major problems before upgrading

The problems in the production line were mainly reflected in energy consumption and environmental protection, as follows:

The preheater system had high resistance, high outlet temperature, high dust concentration, and more heat taken away by the kiln gas, resulting in high system energy consumption.

The calciner had small volume, which was not conducive to the burnout of pulverized coal; the high CO concentration at the preheater outlet was not conducive to the application of self-denitrification technology.

The preheater had high surface temperature, the system had more heat dissipation, and the heat consumption increased.

The preheater steel structure, preheater and tertiary air duct were subject to severe corrosion and there existed potential safety hazards.

The existing cooler had low heat recovery rate, low secondary and tertiary air temperatures, and the outgoing clinker temperature was as high as 200 °C. The clinker quenching effect was poor, which had an adverse impact on the quality of clinker and cement.

The existing cooler had many faults and potential risks, which affected the continuous safe operation.

SNCR denitration technology was used in the production line before upgrading. The NOx emission concentration was 100 mg/m3, which failed to conform to emission requirements of the local government. The ammonia consumption was 5.4 kg/t.cl, with high cost.

The fuel consumption of clinker was 770 kcal/kg.cl, which failed to conform to the Level 2 index requirements in GB 16780-2021 The Norm of Energy Consumption of Cement, nor could it conform to the requirements on reducing pollution and carbon policy in the industry.

3 Upgrading objectives

In order to achieve the goal of reducing pollution and carbon in the CUCC (Xuzhou) clinker production line, it was planned to implement the upgrading of the pyro system. The main objectives included:

Fuel consumption: fuel consumption ≤ 651 kcal/kg.cl

Environmental protection: adopt self-denitration technology to control the NOx background concentration ≤ 400 mg/Nm3, and cooperate with precise SNCR technology so that the NOx emission concentration ≤ 50 mg/Nm3

4 Upgrading plan of rotary kiln

4.1 Upgrading of preheater

4.1.1 Low-energy consumption self-denitrification upgrading of calciner

The existing calciner had small overall volume (-3400m3), and the pulverized coal in the calciner was not burnt completely. Therefore, it is necessary to increase the height upward and add a low-resistance elbow on the existing calciner, turn the downward pipe out of the tower and return to the two original pipes in the calciner, so as to effectively improve the residence time of gas in the furnace and the burnout of pulverized coal. The volume of the calciner could be increased to 6300 m3 after upgrading.

Based on capacity expansion of the calciner, this technological upgrading was to carry out deep self-denitrification upgrading, optimize the position of air, coal and material, lower the position of the coal pipe, and provided an additional coal pipe below the necking of the flue gas chamber so as to increase the volume of the strong reduction area of the calciner, extend the reduction time of nitrogen oxide, improve the reduction efficiency and reduce the background concentration of nitrogen oxide.

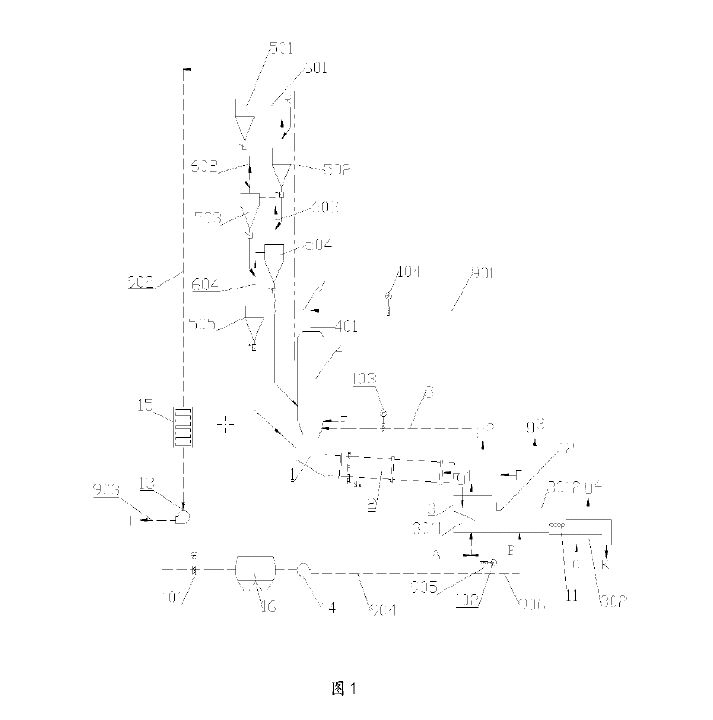

4.1.2 Upgrading the five-stage preheater to six-stage preheater

The outlet temperature of the preheater was 340 °C, and the heat taken away by waste gas was >710.6 kJ/kg.cl before upgrading, which was much higher than that of the low-energy production line. We decided to adopt second-generation cement production technology – high-energy efficiency and low-resistance six-stage preheater, where the existing five-stage preheater was upgraded into a six-stage preheater with weak vortex, low resistance and high efficiency. In order to ensure the reasonable resistance of the preheater and further reduce the electricity consumption, the low-resistance cyclone with weak eddy current at all stages of the preheater was upgraded to reduce the resistance, particularly the cyclone other than the top one, namely, C1-C4 cyclone.

The top-stage cyclone of the preheater was the last cyclone through which the flue gas from the kiln passes. It was required to have high material separation efficiency, reduce dust concentration of flue gas from the preheater, and reduce the heat taken away by flue gas from the preheater. The top-stage cyclone of the original preheater had low material separation efficiency, and the equipment was damaged, thus it will be removed during the upgrading. The existing top-stage cyclone floor will be used as the support floor for the new C5 cyclone, on which basis the civil structure will be added with a new floor, and four new C6 high-efficiency top-stage cyclones will be set on the new floor. The main floor and beam of the original preheater remained basically unchanged, saving the upgrading cost. Refer to Figure 2 for comparisons before and after the upgrading.

4.2 Upgrading in the kiln

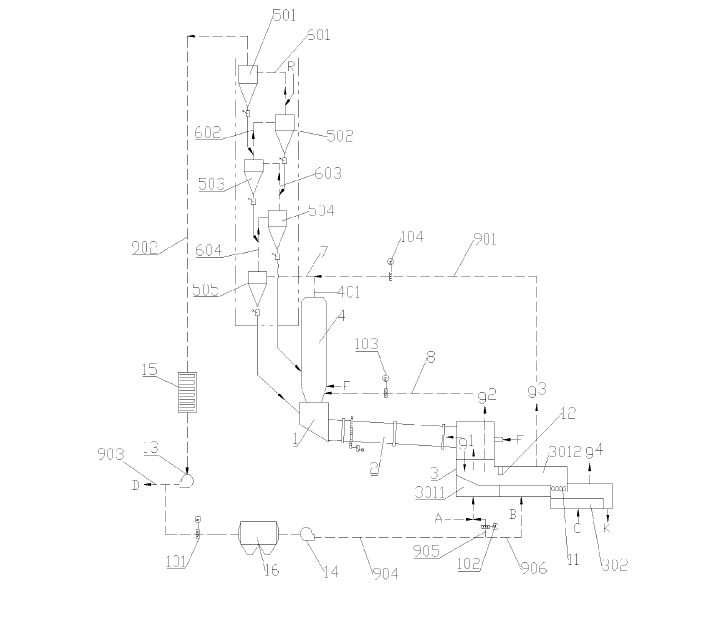

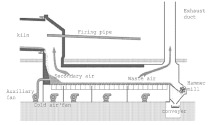

The diameter of the existing tertiary air duct of the rotary kiln was Φ 3.35 m, with smaller diameter, and the tertiary air duct and refractory bricks suffered serious damage. With consideration of the requirements of energy conservation and consumption reduction, the existing tertiary air duct was replaced with a diameter Φ 3.9 m tertiary air duct, and ventilation was strengthened to reduce surface heat dissipation and ensure tertiary air temperature.

The sizes for kiln hood and tertiary air duct were recalculated during the upgrading, the ventilation area was increased to reduce dust. Refer to Figure 3 for comparison before and after upgrading of the tertiary air duct in the kiln. The rotary kiln speed could be increased from 4.0 r/min to 5.0 r/min after upgrading, matching with the corresponding drive.

4.3 Upgrading of the cooler

The existing cooler was a CP cooler with grate bed area of 250 m2 before upgrading. With the increase of cooler operation time, the failure rate increased, the heat recovery rate was low, and the outgoing clinker temperature was as high as 200 °C. In order to improve the heat recovery rate, the CP cooler was replaced with a fourth-generation cooler having intermediate roller crusher, with model of SCLW6-12×13-CM. The grate area of the new cooler could be increased to 316 m2 after upgrading. The first section of the cooler had 9 chambers, and the second section had 5 chambers. The total installed capacity of the 18 cooling fans was 3516 kW. The secondary and tertiary air, the air for coal mill, and the air intake for waste heat recovery generation were calculated and partially upgraded.

4.4 Summary of the upgrading plans (see Table 3)

5 Performance after upgrading

5.1 Data analysis

The upgrading started on March 2022, and was finished on August 4th. Commissioning finished by the end of August. The comparison of production line operation before and after the upgrading was shown in Table 5. The average outlet temperature of the preheater was 262 °C upon upgrading, which was 83 °C lower than that before. The dust concentration of waste gas decreased by 75 mg/Nm3, the heat carried by waste gas and dust at kiln end decreased, saving coal by -70 kcal/kg.cl, and the CO concentration at outlet was below 400 ppm. The coal consumption was saved by -10.5 kcal/kg.cl by improving incomplete combustion; the secondary and tertiary air temperatures were increased to 1207 °C and 960 °C respectively. The heat recovery efficiency of the cooler was improved, and the speed of the rotary kiln was increased to 3.8-4.0 r/min, making the operation more stable. The fuel consumption of clinker was reduced by 98 kcal/kg.cl, the electricity consumption was reduced by 6.5 kW·h/t.cl, the burning efficiency was increased from -55.0% to -63%, thus energy utilization efficiency of the clinker preparation system was effectively improved.

The thermal parameters of key parts of the pyro system were tested during operation, as shown in Table 5. It can be seen from Table 4 and Table 5 that the NOx concentration of the calciner was 315 ppm before ammonia injection, the ammonia consumption was 2.1 kg/t.cl, and the NOx emission concentration was <50 mg/Nm3 at the initial stage of operation, which was 3.3 kg/t.cl lower than that before the upgrading. The NOx emission concentration in autumn and winter was <25 mg/Nm3 as required by the local government during the subsequent operation, striving to reach 18 mg/Nm3. By controlling the opening of the denitration air duct at 60%, the background NOx concentration was reduced to 204 ppm, and the ammonia consumption was 3.6 kg/t.cl. The NOx background concentration (converted into 250-350 mg/Nm3 by 10% O2) of the pyro system was reduced through self-denitrification, and the environmental protection cost was reduced. There were 16 SNCR ammonia injectors in the pryo system. The system has low CO concentration and complete fuel combustion, which not only realized low-coal consumption in pyro system, but also created favorable conditions for ammonia nitrogen reaction in the SNCR system. Refer to Figure 4 for the central control operation of the pyro system upgraded.

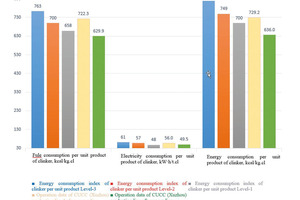

5.2 Comparison and analysis of energy consumption

Green and low-carbon technology was applied during the upgrading of the CUCC (Xuzhou) 10000 t/d clinker production line. The comparison of energy consumption data after upgrading with GB 16780-2021 standard data is shown in Table 8 and Figure 5. The fuel consumption was approximately 4% lower than the fuel consumption index per unit product of Level-1 energy efficiency clinker as required in GB 16780-2021 after upgrading. Meanwhile, it has achieved ultra-low NOx emissions through implementation of calciner self-denitrification source emission reduction technology and SNCR technology, saving approximately 43000 t of standard coal per year, reducing CO2 emissions by 108000 t with low-coal consumption technology, and saving 10000 t ammonia consumption with self-denitrification technology.

6 Conclusion

The technological upgrading of the CUCC (Xuzhou) 10000 t/d clinker production line from five-stage preheater to six-stage preheater had improved the level of large-scale technology and equipment in China’s cement production, and provided an upgrading example for other large-scale cement production lines to carry out green and low-carbon optimization and upgrading. Upon completion of upgrading, the system thermal efficiency was improved, the fuel consumption index was advanced, ultra-low NOx emission was realized, and ammonia consumption was significantly reduced, reaching the expected upgrading goal, effectively promoting the green and sustainable development of cement manufacturing enterprises.

sioning and Production Practice of 10000 t/d Cement Production System Integration [J]. China Cement, 2012, (1): pp. 48-53