Recycling of calcium sulfate screeds – reuse as a binder component

1 Introduction

Gypsum is an important building material for interior finishing in industrial and residential construction. In addition to gypsum plasterboard and gypsum wallboard, calcium sulfate-containing building materials are used in the form of screeds for floors and on wall and ceiling surfaces as plaster. Approximately 55% of the demand for raw gypsum is currently still met by flue gas desulfurization gypsum (FGD gypsum, a by-product of coal-fired power generation) [1]. Approximately 45% of the raw materials are supplied by the mining of natural gypsum [1]. In line with national and international climate protection targets and the associated gradual decommissioning of coal-fired power plants due to the energy transition, the supply of FGD gypsum to the gypsum industry will decline significantly. Reusing gypsum as a valuable raw material in the material cycle will therefore become an even higher priority. Today, plasterboard is used as an important source of supply for gypsum recycling [1]. In order to counteract the foreseeable drastic shortage of gypsum and the increased mining of natural gypsum, previously unused sources of calcium sulfate must be identified, investigated, evaluated, and technologies for their use developed. One resource that has not yet been recorded and utilized, but which is significant in terms of quantity, could be recycled calcium sulfate screeds. Calcium sulfate screeds have been installed in large quantities since the mid-1970s. In 2022, calcium sulfate flowing screeds (CAF) had a market share of 28%, and conventional calcium sulfate screeds (non-flowing) had a market share of around 9%. In total, approximately 40% (approx. 1.3 million m³) of the German screed market consisted of calcium sulfate screeds [3].

Calcium sulfate building materials contain additives to ensure the necessary processing and product properties, which could influence the properties of recycled products (RC) or even prevent recycling-compatible processing. The core objective of the “WIR! Gypsum Recycling Additives” [2] project was to investigate the extent to which these additives are still present in the systems after the thermal production of a recycled thermoanhydrite (RTA) and the extent to which they influence the application. The ultimate goal was to develop robust and high-performance RTA and to prove its suitability in laboratory and field tests. To this end, various test formulations with different RTAs and additives were produced and comprehensively evaluated.

2 Starting materials and production of recycled thermoanhydrite (RTA)

In order to reflect the diversity of systems on the market and to arrive at statements that could be generalized as far as possible, various calcium sulfate flowing screeds (CAF) were selected that differed in both the type of binder and the aggregate.

The aim was to identify possible differences in the mechanical processing of recycled CAF (RC) and its thermal treatment to produce recycled thermoanhydrite (RTA).

2.1 Recycled materials used

The following were used:

Binder compounds for CAF supplied by dry mortar manufacturers, basis for laboratory production of screed panels

Removed CAF, supplied by dry mortar manufacturers in panel form (practical CAF)

Hardened CAF residues from truck mixers

The corresponding CAF used for the recycling process contains different binders (alpha-hemihydrate (α-HH), synthetic anhydrite, natural anhydrite, and thermoanhydrite) as well as aggregates made of natural anhydrite or natural sand/quartz sand (Table 1). The crystal water and calcium sulfate dihydrate contents were determined for the starting materials (RC). The calcium sulfate dihydrate content of 39% to 48% (Table 1) indicates the recyclable gypsum content.

2.2 Production of RTA

The mechanical processing of the CAF from Table 1 was carried out in various stages as shown in Figure 1. After pre-crushing, the material was further processed in a jaw crusher. The fine material (0–1 mm) from the crushing process was fired in a chamber furnace at 500 °C for 4 hours to produce recycled thermoanhydrite (RTA 1 to RTA 6). The fired RTA based on the 0–1 mm fractions was not further processed and was used in the screed systems without grinding. The RTA obtained after firing was extensively characterized. The coarse material > 1 mm from the crushing process was not used in CAF development and was only used for the enrichment tests (Chapter 3.4).

3. Characterization of the RTA

3.1 Additive residue quantities in the RTA

A central task of the project was to examine the extent to which the additives present in the original CAF were still present in the manufactured RTA after thermal treatment and whether they were capable of negatively influencing the properties of these recycled anhydrites. Any additive residues that might still be present were detected using various methods. First, the organic molecules or additive residues were qualitatively and quantitatively determined using Fourier transform infrared spectrometry with a Nicolet iN10 FTIR spectrometer with ATR recording and an external iZ10 FTIR module from Thermo Fischer Scientific. The evaluation was carried out using Omnic software by the Bauhaus University Weimar. To confirm the results, a double determination was carried out using the Bruker IR spectrometer Tensor 27 with ATR recording from Sika Deutschland GmbH.

With the help of the FTIR spectrometer (Figure 2), none of the additives used in the CAF (flow agents, retarders, stabilizers) were detected in the recycled and burned RTA within the limits of the method and using the solvents employed. It can therefore be assumed that all additives decompose almost completely at a firing temperature of 500 °C. In the further utilization of RTA as a binder, this simplifies the formulation of CAF (contamination by old additives does not have to be taken into account).

In order to confirm the results of the FTIR analyses, additional analyses were carried out using infrared spectroscopy (IR – Sika) for the qualitative and quantitative characterization of organic molecules and additive residues. These measurements also failed to detect any additives in the combustion products after the fire.

3.2 Phase composition of the RTA

The identification of the main and secondary mineral phases of the RTA was determined using X-ray powder diffractometry. The measurements were performed with a Bruker D8eco X-ray diffractometer in theta-theta configuration, equipped with a copper anode and a LynxEye XE-T detector. The measurement conditions were 40 kV/25 mA power, a measurement range from 5° to 60° 2 Theta, step size 0.01° with 0.1 s/step counting time, automatic divergence apertures, and 2.5° Soller apertures.

Qualitative phase analysis was performed using the EVA Ver. 15 software suite (Bruker AXS) against the PDF-2 database. The subsequent quantification of the identified phases by Rietveld refinement was performed using Profex 5.3 [4].

Total RTA

The activity of higher-fired “screed gypsum” is mainly determined by the anhydrite phase AIIs (s=slightly soluble). The proportion in the manufactured RTA varies between 4% for RTA 6 and 25% for RTA 4 (Table 2). The differences may be caused by varying calcium sulfate dihydrate content in the RC raw material (see Table 1) and varying particle distribution of the fired material. In addition to anhydrite IIs, other reactive gypsum phases such as anhydrite AIII and calcium sulfate hemihydrate were detected to a lesser extent.

Analysis of different grain fractions

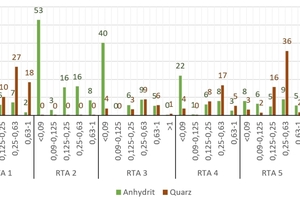

In order to understand the causes of the influence of the CAF’s granulometry in the finest range on the properties of the system, the various RTAs were used to classify the 0–1 mm fraction again in detail and characterize it mineralogically in the classes.

The results of the investigations are shown in Figure 3. The total fraction 0–1 mm was divided into the individual fractions < 90 µm, < 125 µm, < 250 µm, < 630 µm, and < 1 mm. The anhydrite and quartz content in the fractions was specified. The figures show relative proportions within the fractions, which can add up to a maximum of 100%. As expected, due to the different hardness of the materials, anhydrite was enriched in the finer fractions and quartz in the coarser fractions.

Overall, the quartz proportions in the different systems vary widely. High quartz proportions of up to 40% in the individual fractions, as was evident in the RTA 1, RTA 5, and RTA 6 systems, led to lower strengths in subsequent tests due to the inert nature of quartz in the corresponding CAF.

3.3 Granulometry of the RTA

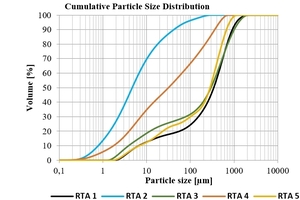

The granulometry of the different RTAs was determined by measuring the particle size distributions using a BECKMAN COULTER LS 13 320XR laser particle analyzer, on the basis of which the corresponding parameters were then calculated. The results show (Table 3, Figure 4) that the RTA differ significantly in terms of their granulometry. While RTA 1, RTA 3, and RTA 5 have very similar particle size distributions, RTA 4 and, in particular, RTA 2 have significantly finer distributions. This indicates that the type of grain size (RTA 2 natural anhydrite as opposed to quartz in all other RTA variants) in particular, but also the type of binder (RTA 4 pure alpha hemihydrate as opposed to anhydrite or mixtures in the other RTA variants) play a decisive role in the granulometry of the materials.

3.4 Enrichment of the gypsum content through further processing steps

Through further processing of the previously unused RTA fractions 1–2 mm and 2–4 mm, an attempt was made to enrich calcium sulfate particles smaller than 2 mm or 0.5 mm and to potentially utilize these materials as well. To this end, the RC 5 material in the 1–2 mm and 2–4 mm fractions was fed into a hammer mill (Figure 5). Various parameters were varied (tests V 1 to V 3, see Table 4). The feed quantity was 300 g to 1000 g, and the grinding time was 20 seconds. The screen insert in the hammer mill varied in the range from 0.5 mm to 2 mm.

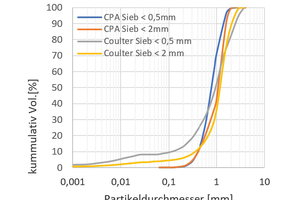

The particle sum curves measured using optical CPA methods (Computerized Particle Analyzer, Harver–CPA–4) and laser granulometers (LS 13 320XR) from the sieve passage with a sieve insert of 0.5 mm and 2 mm in the hammer mill show a similar pattern (Figure 6). However, the values measured with the laser granulometer are realistically higher in the fine fraction, as this range is not covered by the CPA method with a measurable particle lower limit of 250 µm.

Table 4 lists the RC 5 tests with fractions 1–2 mm and 2–4 mm in the hammer mill. The key finding was that these coarse fractions can also be used for RTA production if the binder content is enriched by a further processing step. The highest KW content was achieved in tests V1 and V3.3 in the sieve passage with 8.7% KW in each case, which corresponds to a quantity of calcium sulfate dihydrate of 42% in each case. However, in all other cases, an enrichment of calcium sulfate dihydrate was also achieved in the pass, whereby only those variants in which sufficient pass quantities can be generated are technically usable. Against this background, variants V 3.1 and, in particular, V 3.2 would be eliminated.

4 Investigations on model systems

4.1 Additives used

The rheological properties of the RTA-based CAF screeds were adjusted using high-performance PCE-based superplasticizers. The setting process was controlled using retarders. Extensive preliminary tests were carried out with the retarders and superplasticizers (Table 5) in order to set the optimum processing time and find a suitable flow behavior for the screeds. In addition to the conventional commercially available superplasticizers and retarders from Table 5, new retarder/superplasticizer combinations were also tested during the course of the project.

4.2 Preliminary investigations on RTA model systems

In a first step, a very simple model system of calcium sulfate flowing screed (CAF) was used with the combination of 3% white lime hydrate CL 90 and 0.60% potassium sulfate based on calcined recycled thermoanhydrite (RTA) with and without superplasticizer. Basic properties such as flow, processing time (consistency retention), and strength were determined.

RTA without additives, water requirement, slump and start of setting

The water-to-solid ratio (W/S) of the RTA was set in a range from 0.32 to 0.40 so that a target consistency of 170 to 205 mm slump was achieved. The start of stiffening [7] for all RTA was between 60 and 80 min. The only exception was RTA 3, which started to stiffen after 150 min (Table 6).

RTA with superplasticizers and retarders

In the next step, the RTA were combined with various retarders and superplasticizers. Superplasticizers are essential for adjusting the flowability and reducing the water requirement for sufficient compressive and flexural strength in flowing screeds. Without retarders, various RTAs in combination with superplasticizers stiffen too quickly and cannot be processed.

All superplasticizers listed in Table 5 were used in the investigations. The superplasticizer concentration used was 0.10 M-% in each case. The addition of retarder V1 in system RTA 3 with superplasticizers and V2 in system RTA 4 with superplasticizers was necessary because very rapid stiffening was observed in the respective samples, which would have made processing or testing impossible. Retarders V1 and V2 were added in a concentration of 0.05 M% each.

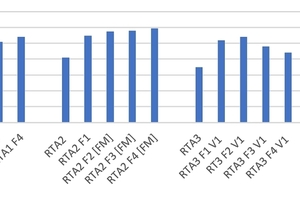

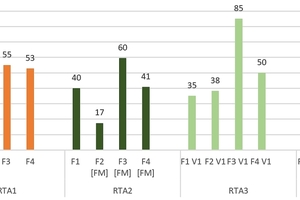

The consistency measurements were carried out uniformly with a water/solid value of 0.38 (with the exception of RTA1 - W/F value 0.32). With all superplasticizers, the workability of the systems could be significantly increased compared to FM-free systems. Depending on the RTA and FM, an increase in flowability of 20% to 55% was achieved compared to pure RTA (Figure 7). In three samples of RTA 2 and one sample of RTA 4, the slump could no longer be determined due to the effective action of the superplasticizers. In these cases, the flow measure (marked with [FM]) was determined instead.

In addition to the initial consistency, the processing window is also of crucial importance for a CAF. The end of the processing time is the time at which the original slump (flow) of the mortar has decreased by ≥ 20%. In practice, a minimum processing time of 30 minutes is required for CAF. The results of consistency retention (re-stiffening) in Figure 8 show a very differentiated picture for the different systems. RTA 4 exhibits rapid re-stiffening with all superplasticizer variants, despite the use of retarders. None of the variants achieves the minimum processing time. In all other cases, the required processing window of 30 minutes is maintained by the RTAs, with the exception of RTA 2 with FM 2. However, there are significant differences depending on the binder and superplasticizer used. FM 3 generally seems to lead to very favorable consistency retention.

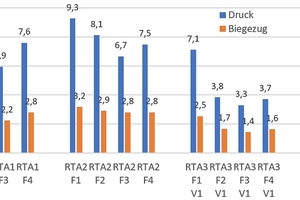

Hardening process and strengths

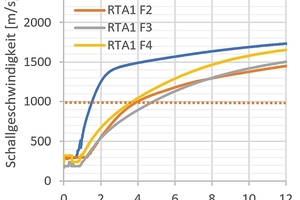

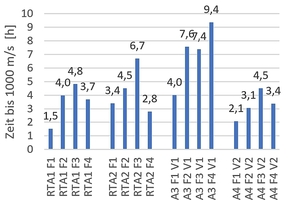

The hardening process in the first 24 hours was characterized by measuring the ultrasonic velocity. This made it possible to identify differences caused by superplasticizers in the first phase of strength development (12 hours). The processes are particularly easy to compare in the RTA 1 system, as no retarders were used here (Figure 9). It can be seen that the PCE superplasticizers (F2, F3, F4) delay more strongly than the melamine-based superplasticizer F1, although the differences between the PCEs are only minor. A comparison of all systems is shown in Figure 10. In addition to the different effects of the superplasticizers, it can be seen that the addition of retarders has a particularly strong effect in the RTA 3 system.

Figure 11 shows that all model formulations used with RTA are capable of generating compressive and flexural strengths independently. Individually, different strength levels result, whereby the addition of the retarder in the RTA 3 system leads to a significant drop in compressive strength to a level < 4 N/mm². The generation of strength is a basic prerequisite for the subsequent use of RTA in CAF, whereby the measured strengths are in no case sufficient to produce CAF that is suitable for practical use. This suggests that a 100% replacement of the binder with RTA will not be possible in real CAF systems and that the replacement can only be partial. This was taken into account when formulating a CAF based on RTA.

5 Development of a practical CAF based on RTA

In order to provide a practical CAF based on RTA, various recipe adjustments were made on the basis of preliminary investigations.

In the basic recipe, the proportion of natural anhydrite was first completely replaced by RTA, as in the model tests. Initial results showed that this approach is not feasible due to two main factors:

1. Depending on the source recyclates, RTA contains varying amounts of inert aggregate and powder, which cannot contribute to strength. These are often components that originate from the original quartz aggregate or limestone aggregate. This dilution of the reactive binder must be taken into account

2. When using RTA, very high water additions were necessary (only partially compensable by FM) in order to achieve sufficient flow behavior. This has a negative effect on strength

In the first approach, the degree of substitution of natural anhydrite by RTA was therefore gradually reduced. With an application quantity of 8% RTA and 19% natural anhydrite based on the total amount of CAF, improved processing was initially achieved. However, the strength levels were still too low. Since it was assumed that these strength deficits were primarily caused by the inert components in the RTA, further tests were conducted in which the RTA content in the CAF was increased to 15% while maintaining a constant natural anhydrite content (19%) in order to obtain a sufficient active ingredient content in the total binder. As a result, the measures mentioned above led to a significant improvement in strength development, although the requirement for a 28-day compressive strength of > 25 N/mm² could still not be met.

A decisive improvement in strength was achieved, at least in part, by adding small proportions of a hydraulic activator. The strength development could be increased to over 30 N/mm² after 28 d when using 8% RTA 2 (the aggregate used here was natural anhydrite in the initial CAF). However, in other systems with quartz aggregate in the initial CAF, the target was not achieved when using 8% RTA. When using RTA 3 and RTA 5, despite the activator, only compressive strengths of 17–20 N/mm² were achieved after 28 d. Even with RTA 4, the standard requirement of F5-C25 with 18 N/mm² was significantly undershot.

In addition to the amount of RTA used in the CAF and, if necessary, the addition of a hydraulic activator, it was also deemed necessary to optimize the type of superplasticizer in order to further optimize the overall system. Preliminary tests showed that conventional superplasticizers in combination with RTA were not yet able to achieve the desired flow behavior.

Therefore, an increased water addition of up to 18% was necessary to achieve the flow properties, which had a very negative effect on strength development. For this reason, a new, adapted superplasticizer concept was developed in the course of the project. A high-performance superplasticizer was developed as an additive for the precise adjustment of the technical properties of the CAF.

This is a PCE-based superplasticizer (Sika ViscoCrete®-10200362 PowerPack) with an adapted molecular weight distribution, length, and number of side chains. The newly developed superplasticizer was tested with RTA 3, whereby the subsequent sample surface was then produced with RTA 6 due to the available quantities of RTA. By using the high-performance superplasticizer, the water requirement was reduced to 15% with a flow measure of 254 mm. As a result, using 8% of RTA 3 in the CAF increased the compressive strength from 17 N/mm² to 21.5 N/mm² after 28 d.

As a result of the formulation adjustment, it can be concluded that the use of all RTAs in CAF is fundamentally possible and can be controlled by varying the addition quantities (8 to 15%). The use of novel, adapted additives led to a significant improvement in the material properties in CAF.

Despite various adjustments to the amount of RTA used and the use of optimized additives, the requirements of an F5-C25 could not be consistently met. However, the values determined correspond to an F4-C20, which would cover a large proportion of single-family homes. Further formulation adjustments and research may contribute to a further improvement in the values, so that F 5-C25 screeds based on RTA will certainly be achievable in the future.

6 Production of a sample surface with the developed CAF based on RTA

After completion of the laboratory tests, a CAF sample surface was created in the technical center with RTA as a proportionate binder and the newly developed superplasticizer using a commercially available retarder.

A formulation with 15% RTA 6 and 19% natural anhydrite (based on the CAF) served as the basic recipe for an application test, as good results were achieved with this amount in the laboratory tests. A final evaluation and suitability for use on the construction site was carried out by means of machine processing using a mixing pump. For this purpose, 700 kg of CAF (with 15% RTA 6) was produced on a mixing plant and poured over an area of approx. 12 m². The installation height corresponded to the usual minimum thickness of 4 cm. Mixing was carried out in a practical manner for bagged goods using a 2-mixing zone duomix plastering machine. The consistency was adjusted to a flow rate of 39 cm using a 1.3 l test container.

The material exhibited very good flow properties (Figure 12) and was easy to process (Figure 13). There was no settling of the grain size and no sintering layer formation, which could later have a negative effect on the drying behavior. The setting time was measured in the laboratory using a Vicat device. A setting time of 40 minutes was achieved, similar to the reference formulation. The surface was walkable after 24 hours. This corresponds to standard CAF products on the market.

A sample was taken from the machine‘s hose and the change in length and compressive strength were determined. The change in length (swelling/shrinkage behavior) was measured in a “screed rail” so that measurements could begin immediately after the CAF was applied. A very slight initial swelling of up to 0.11 mm/m was recorded, which corresponds to normal expansion. After just 7 days, no further change in length was measured. The compressive strength determined after 28 days was 22 N/mm² and the flexural strength was 5.2 N/mm².

As a result, a final formulation was successfully used in practical trials, with properties corresponding to CAF quality class CAF-F5-C20. The proportion of RTA was 15% in a mixture with natural anhydrite. The processing properties and also the surface texture (Figure 14) corresponded to standard products on the market. Examination of the cross-section of the screed surface revealed good integration of the grain size up to the upper layer, so that no settling occurred. There was also no sintered layer. This proved that it is possible to develop a marketable product based on recycled thermoanhydrite.

7. Summary and outlook

The recycling of calcium sulfate systems is becoming increasingly important in light of the end of coal-fired power generation and the associated elimination of FGD gypsum.

In this project, recycled thermoanhydrite was produced and comprehensively evaluated on the basis of various calcium sulfate-based (CAF) recycled screeds. The key findings are summarized below.

First, it was demonstrated that the organic additives present in the initial systems are no longer present in the binder after the production of recycled thermoanhydrite (RTA). This is an important finding that makes it possible to implement a continuous formulation based on RTA without having to take into account residual quantities of remaining additives.

The properties of the RTA produced depend heavily on the quantity and type of aggregate present in the original CAF. It is inert in the subsequent RTA and dilutes the binder content. Subsequent crushing (increase in fine content) during processing means that systems based on anhydrite as aggregate exhibit higher strengths than those with quartz or limestone.

Achieving a flowable consistency is challenging with RTA and, despite the use of modern superplasticizers, was initially only possible with increased water addition. The development of a high-performance superplasticizer with a new molecular architecture adapted to the system significantly improved the workability of the systems and reduced the water requirement considerably.

Due to the above factors, it is not possible to replace 100% of the binder in CAF with RTA. However, recycled thermoanhydrite from calcium sulfate-containing screeds is able to make a significant contribution to the strength of CAF, so that a proportional substitution of the binder is possible. Based on the current results, further processing in factory-dry or factory-fresh mortars by adding a proportion of CAF is considered to be very promising. It has been proven that CAF formulations with recycled thermoanhydrite (RTA) can be adjusted through optimization with newly adapted superplasticizers and retarders so that they can be used in practice without restrictions. Flowability, processing time (consistency retention), and strength development with RTA meet the specified requirements. A very good CAF with a closed surface appearance without bleeding and without a sintered layer is achieved without surface bleeding. The CAF class CAF-F5-C20 achieved in the final test can already be used for the majority of screeds in residential construction.

From a scientific and technical point of view, the results form the basis for further research activities and trials at interested companies that manufacture gypsum binders and dry mortars. A realistic goal for the near future is to achieve a CAF-F5-C25, which accounts for the largest volume share in residential construction.

Until now, calcium sulfate screeds have not been disposed of as construction waste and recycled in Germany. The project has thus opened the door to a completely new, sustainable group of materials in the screed sector that is capable of conserving natural resources and effectively closing material cycles. Solutions have been developed to generate a recyclable material (binder) from a waste material (calcium sulfate screed). This binder (RTA) can replace about 50% of calcium sulfate binders (natural and thermoanhydrite, synthetic anhydrite, or calcium sulfate alpha hemihydrate). This makes the recycling of CAF economically interesting and feasible.

However, in order to be able to put the knowledge gained into practice, the regulatory framework must first be created. Existing quality management systems, quality recommendations, and analysis methods for recycled gypsum are available [5]. Important technical parameters that must be observed, such as moisture content of < 5% by weight (< 10% for agreed particle size > 1 mm as bulk material) and calcium sulfate dihydrate content > 85% by weight have been agreed between the gypsum industry and RC gypsum collection and processing sites for plasterboard recycling.Attempts are being made to make gypsum fiberboard with a significantly lower gypsum content and high cellulose fiber content suitable for recycling. The CAF (calcium sulfate screeds) used in practice have a calcium sulfate dihydrate content of 30–50 wt.%. This is significantly below the existing agreement [5] of > 85 M.-%. The existing agreement between the gypsum industry and the recycling collection points/processing plants should therefore include new gypsum recycling products in the future and specify the calcium sulfate dihydrate content for CAF accordingly. The acceptance and separation of calcium sulfate screeds appears sensible and would be the starting signal and an important milestone for the utilization of this gypsum resource. Better separation and a revision of the Waste Catalogue Ordinance (AVV) and industry agreements [5] are recommended as prerequisites for the further development of gypsum recycling.

Acknowledgements

The research project Additives (FKZ 03WIR0308) was funded by the Federal Ministry of Education and Research (BMBF) as part of the program line “WIR! – Change through Innovation in the Region” in the alliance “Gypsum Recycling as an Opportunity for the Southern Harz Region.”

We would also like to thank Saint-Gobain Weber GmbH and CASEA GmbH for providing the screed and binder compound samples.

in Deutschland, September 2021

, Journal of Applied Crystallography 48 (2015), 1573-1580. doi:10.1107/S1600576715014685