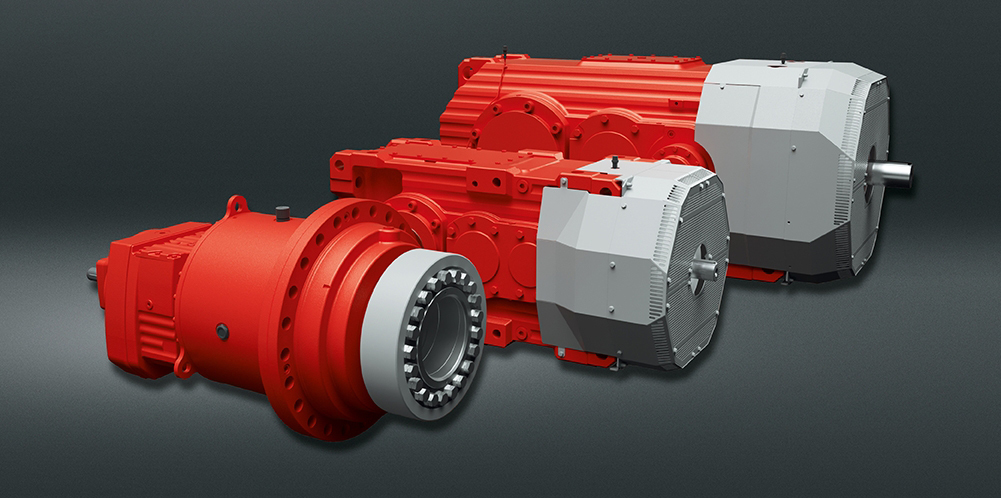

Segmented ring gear made of ADI cast iron

New drive for rotary kilns

The cement plant in Vác, located approximately 35 km north of Budapest on the Danube Bend, is one of the most modern and important cement production facilities in Hungary. It is operated by Duna-Dráva Cement Kft. (DDC), a joint venture between the Heidelberg Materials Group and Schwenk Zement KG. Since its commissioning in 1963, high-quality cement clinker has been produced here – around 2400 t/d. The raw material used is limestone from the nearby Naszály mountain, whose quality contributes significantly to the plant‘s performance.

SEW drive for reliable production

At the heart of production is a rotary kiln with a diameter of 4.2 m, in which the clinker is fired at high temperatures. Its rotation is achieved by a ring gear, which is driven by a powerful drive system. An asynchronous motor provides around 350 kW for this purpose, which is transmitted via an industrial gear unit. This is connected via a coupling to a separately mounted pinion that engages with the ring gear and transmits the required torque. The connection between the ring gear and the kiln shell is made via leaf springs, which enable a flexible yet robust coupling.

The previous drive technology on the rotary kiln was getting on in years. A failure of the support roller bearing of the pinion led to a misalignment between the pinion and the ring gear. The resulting reduction in the contact area caused increased wear on both components. In order to ensure the long-term operational reliability and efficiency of the plant, DDC decided to replace the ring gear and the drive pinion. The choice fell on SEW-Eurodrive, whose expertise in the development and manufacture of high-performance ring gears and drive systems is internationally recognized.

Material with exceptional properties

The new solution from SEW-Eurodrive is based on a segmented ring gear with an outer diameter of 6.1 m and a width of 300 mm. The module of the gearing (measurement for the tooth size) is 40. The number of teeth could be reduced to 152. Particularly noteworthy is the use of high-strength, bainitic cast iron with spheroidal graphite, also known as Austempered Ductile Iron (ADI). This material offers significant advantages over conventional cast steel in terms of tensile strength, elongation, and wear resistance. With a minimum tensile strength of 1000 MPa and a minimum elongation of 5%, ADI meets the highest requirements for industrial applications under continuous load.

To achieve these mechanical properties, targeted heat treatment is required. This treatment causes the desired microstructure to form in the material and gives the gear rim its high strength and load-bearing capacity. The contact fatigue strength resulting from the excellent work hardening properties makes the gear rim – when correctly dimensioned, loaded, and lubricated – extremely resistant and virtually wear-free in operation. In addition, the use of ADI casting enables a significantly more compact and lighter design of the gear rim compared to conventional cast steel solutions. This has a positive effect on handling, assembly, and acquisition costs.

Segmented design for maximum precision

Another key feature of SEW-Eurodrive gear rims is their segmented design. While conventional gear rims usually consist of two to four large segments, the Bruchsal-based drive specialist relies on a multi-part design with particularly compact individual segments. Depending on the overall diameter of the gear rim, these segments measure only 1 to 2 m. This design not only makes handling much easier, but also ensures consistently high manufacturing quality – regardless of the overall size of the gear rim.

Each segment is individually cast, machined, heat treated, and finely finished. This process ensures that the required dimensional accuracy and surface quality are consistently maintained – regardless of whether the gear rim has a diameter of 4 or 16 m. The high initial pitch accuracy of the design complies with ISO 8 and AGMA 9 and ensures optimum running behavior and even load distribution during operation.

The segmented design also offers considerable advantages in terms of transport, installation, and maintenance. The compact segments can be transported in standard containers, eliminating the need for complex special logistics. On site, the segments can either be pre-assembled into two ring gear halves or attached individually directly to the drum. This is a decisive advantage in confined spaces, as is often the case in existing plants. In the event of damage, individual segments can also be replaced selectively without having to dismantle the entire ring gear. This reduces downtime and significantly lowers maintenance costs.

Assembly and alignment with maximum precision

The assembly work began in May 2024 with the pre-assembly of the ring gear segments directly on site in Vác. This was followed in June by the final work on the rotary kiln, including the so-called kiln shot – a process in which a section of the kiln is cut out and replaced with a new segment. The new ring gear was then installed and precisely aligned. The new drive pinion was also installed and positioned optimally in relation to the ring gear to ensure uniform load distribution. Alignment was carried out with the utmost precision to prevent unacceptable vibrations and minimize mechanical stress on the ring gear and periphery.

A key element in the success of the project was the close cooperation between DDC and the experts at SEW-Eurodrive. These specially trained specialists supported the assembly, alignment, and commissioning of the new drive unit. Their in-depth expertise, modern materials technology, and efficient cooperation resulted in an economically convincing and future-oriented solution.

Design improvements

The advantages of the new ADI cast gear ring can be clearly quantified: The width of the gear ring was reduced from the original 500 mm to 300 mm. At the same time, the gear module was increased and the number of teeth reduced. These design adjustments led to a significant reduction in the amount of material used, which is reflected in lower investment costs and reduced lubrication and maintenance expenses. In addition, the high pitch accuracy of the design and the precise alignment during commissioning help to reduce vibrations in the overall system. This minimized the mechanical stress on the gear rim and drive components and increased the operational reliability and service life of the plant.

Teamwork as a success factor

DDC’s decision to use split gear rims from SEW-Eurodrive shows how modern drive technology contributes to the optimization of industrial processes. The combination of innovative materials, sophisticated design, and precise manufacturing has resulted in a durable, low-maintenance solution that meets the requirements of a modern cement plant. The successful implementation of the project in Vác underscores SEW-Eurodrive‘s capabilities as a reliable partner for demanding industrial applications.