Sulfate resistance of alkali-activated slag/metakaolin/fly ash cementitious materials

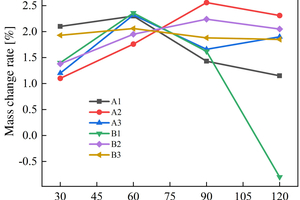

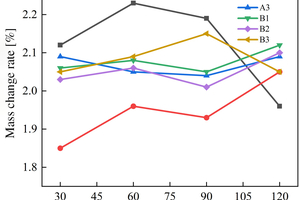

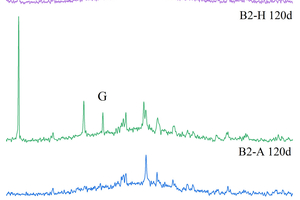

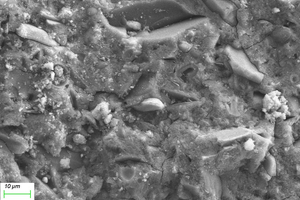

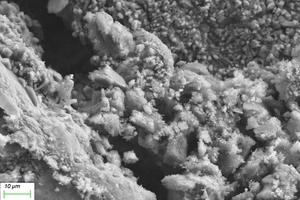

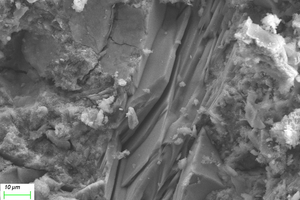

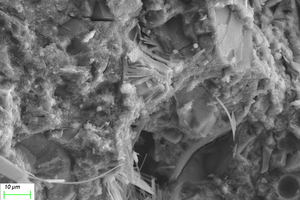

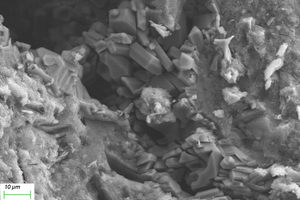

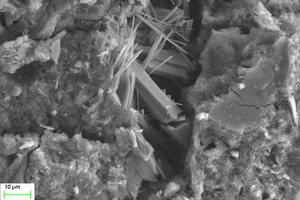

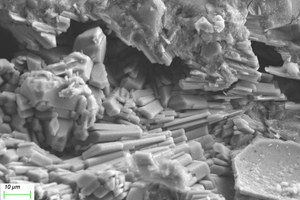

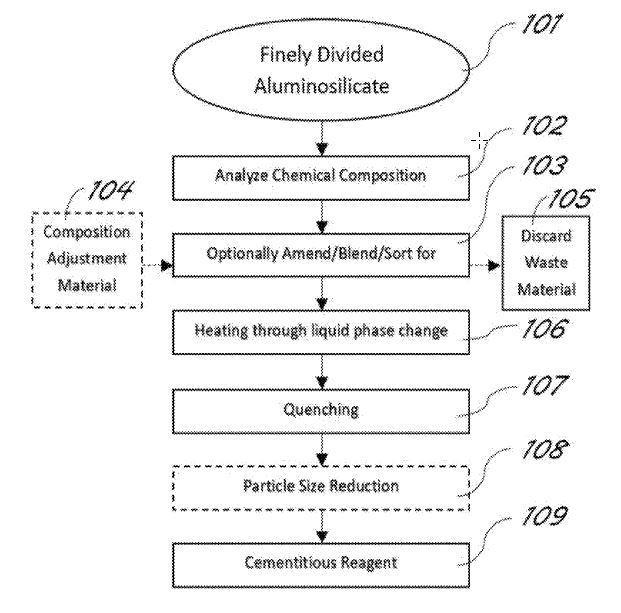

Fly ash, slag powder, and metakaolin were used as the main raw materials to prepare the ternary alkali-activated cementitious materials, and the compound alkali-activated cementitious materials with different proportions were corroded in 5% (NH4)2SO4 solution for 120 d by different immersion methods to study their sulfate resistance. Then X-ray diffraction (XRD) and scanning electron microscopy (SEM) were used to analyze the erosion mechanism of alkali-activated cementitious materials with different mix ratios. Results show that the alkali-activated cementitious material containing 50% slag powder, 25% fly ash and 25% metakaolin shows the best sulfate resistance in (NH4)2SO4 solution and the alkali-activated cementitious material with 60% slag powder, 28% metakaolin and 12% fly ash has the worst corrosion resistance. XRD and SEM analysis confirms the existence of gypsum phase in alkali-activated cementitious materials specimens when exposed to ammonium sulfate, indicating that chemical erosion damage occurs in the interior. These results are expected to provide reference for the theoretical research and practical application of alkali-activated cementitious materials.

1 Introduction

Alkali-activated cementitious material, which is prepared with a large amount of industrial solid waste and alkaline activator according to a certain ratio, is a new building material with simple production process and low cost. It can not only provide an economic and efficient method for the recycling of large industrial solid waste, reduce its impact on the environment, but also play a role in construction and roads fields to reduce unsustain-able resource consumption, with huge environmental, economic, and social benefits, and is one of the main alternatives to silicate cement...