200 years after Louis Vicat

From 06.06.-08.06.2017, around 560 attendees met for the international scientific symposium “The Future of Cement” to discuss with each other the history, present and future. The symposium was dedicated to Louis Vicat.

Louis Vicat

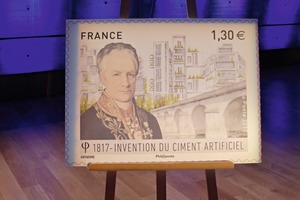

With his work, French engineer Louis Vicat laid the foundations for the development of cement and lime. 200 years after the first publication of his work in the year 1817, the French post office dedicated a special-issue stamp to him in 2017, which was presented at the symposium.

Jean Salençon, Académie des Sciences and Académie des Technologies, opened the technical section of the symposium following the welcome address by Daniel Janicot, President of Commission nationale française pour l’Unesco. In his paper “Louis Vicat’s memoir to the Royal Academy of Science, 15 December 1817”, he also reported on the bridge built by Vicat over the Dordogne in Souillac.

Evolution of cement and concrete

The first part of the papers reviewed the history of cement, from the Romans to Le Chatellier, from hydraulic lime to Portland cement, from cement to concrete, and concrete and heritage as well as the “Contribution of science to the evolution of cement”. Karin Scrivener, EPFL, emphasized in her paper how scientific ideas help systematize practical know-how.

Process innovation

Wednesday morning began with a session on the key topics of energy efficiency, waste valorization and emission control technologies.

In his field-oriented paper “Energy efficiency and CO2 performance – measures and limits”, Bruno de Robert, LafargeHolcim, referenced various examples to explain the successful realization of regionally dedicated measures. In Uganda, the Group is supporting a coffee project “Food and fuel not food or fuel”, where with the use of biomass in the cement plant, CO2 reduction is achieved. Other examples were the utilization of municipal waste in Bulgaria and of wind power in Mexico. In total at LafargeHolcim, 340 MW power is generated from waste heat worldwide. The most important possibilities for CO2 reduction are a lower clinker content in cement, alternative fuels and thermal energy efficiency.

Jan Theulen, HeidelbergCement, addressed “Waste valorization in the cement kiln aiming at circular economy”. He showed that there are major differences in the utilization of waste in Europe. While in Western Europe, the focus is on “waste-to-energy” solutions, in Eastern Europe a good job is being done with much higher “waste-to-cement” solutions. In the biggest cement production country, China, the cement industry has “missed the train”. There, as less than 1 % AF is used in clinker production (< 2 million t/a), “waste-to-energy” can only be growing. Theulen emphasized: “We need local solutions for local waste problems”.

Volker Hoenig, ECRA European Cement Research Academy, explained with reference to two examples in Colleferro and Retznei “Carbon capture, storage and use”. He showed that oxyful operation is possible in different local and plant-specific conditions.

Materials and technologies for the future

In the afternoon, the focus was on materials. Albrecht Wolter, Clausthal University, reported on “Portland-based multi-constituent cements – by-products in cement manufacturing”. Clinker substitution rates amounting to 25 % are state of the art; higher substitution rates will be pushed by climate change; as long as GBFS, fly ash and natural pozzolana are available at low cost, calcined clay will not gain a share as a main constituent in cement.

“CSA and belite-rich clinkers and cements – mechanism and applications” was addressed by Ellis M. Gartner, Imperial College London. One possibility to reduce CO2 emissions in the industry is the use of major alternative clinker types. Gartner presented various low-carbon supplementary cementitious materials (SCM) in concretes and mortars.

Hendrik Möller, Schwenk Group, then provided information on “Novel cements based on calcium-hydrosilicates” and presented a plant layout. The product is currently undergoing extensive testing. There are lots of applications, it is also possible to produce porous structures for thermally insulating materials. One feature of the new material is very low heat of hydration (< 150 J/g) compared with LH cement (< 270 J/g) and VLH cement (< 220 J/g).

In the last papers session, geopolymers and UHPFRC and results on concrete durability were presented.

Concrete for smart cities and sustainable applications

The third day of papers was dedicated to application. Besides “Lifecycle assessment of cement and concrete”, the French national project on recycling concrete “Performance of concrete with recycled concrete fines” was on the agenda. In this 5-million € research programme, 47 industrial and academic partners are involved. Presented was a publication in which the state of the art and all major scientific findings are presented. Another interesting topic is energy storage. Prof. Pal G. Bergan, EnergyNest AS, presented a possibility for storage, the “thermal battery cell” stores heat energy in a special concrete material developed with HeidelbergCement.

Recent achievements, new trends

The papers sessions concluded with fascinating case studies such as 3D robot extrusion, concrete in tunnels and concrete for MOSE, Venice’s protection system against floods. Closing the event, two French architects talked about “Architectural perspectives on the city of tomorrow” in a panel discussion.

The symposium was supported by a poster exhibition of young scientists, who presented their research findings to the audience of professionals.

//www.futureofcement2017.com" target="_blank" >www.futureofcement2017.com:www.futureofcement2017.com