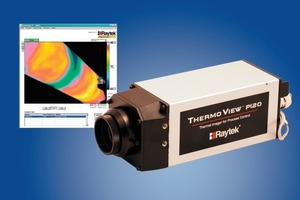

New thermography solution

Designed for automated monitoring and control of continuous or stationary targets, the ThermoView Pi20 fixed-mounted process imager from Raytek provides a real-time process view of thermal images. Featuring an IP54 rating, the rugged ThermoView Pi20 camera (Fig.) is offered in two temperature ranges: –40 to 500 °C and 200 to 2000 °C. For each temperature range, two lens options are available: 21.7 ° x 16 ° or 30 ° x 22 °. The ThermoView Pi20 camera is easily interfaced to the DataTemp Pi software for real-time viewing, archiving and playback of both on-line and off-line thermal images.

Raytek GmbH, Berlin (D), Tel.: +49 (0)30 478008-0,

Fax: +49 (0)30 4710251, Raytek@Raytek.de