The automated dosing of admixtures in the production of dry premix mortars (Part 1)

Summary: Without the use of ever more effective additives modern dry premix mortars and thus, the continuously increasing number of innovative special products used in modern architecture would not exist, and many technical properties could not be achieved. Although dry premix mortar plants operating on an industrial scale are now practically entirely automated in terms of dosing of major raw components and their further processing, most of the small scale components (in particular so additives, pigments and fibres) are still weighed and added manually. This results in an increasing risk of deviations in the quality of the final product, caused by so-called “human error”. Whilst part 1 is explaining the theoretical background of admixtures in dry premix mortars in brief, part 2 is focusing on the new developments to overcome afore mentioned problems by means of most reliable and affordable systems for fully automated dosing of admixtures.

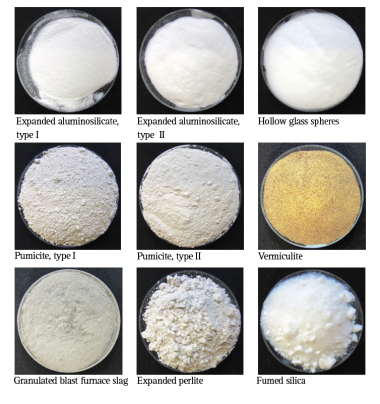

Without the use of admixtures, especially ever more effective additives, modern dry premix mortars (and in particular so the continuously increasing number of innovative special products) would not exist, and many technical properties could not be achieved. Plants for the production of dry premix mortars (Fig. 1) operating on an industrial scale are now practically entirely automated in terms of the major raw components and their further processing [1]. Nevertheless, most of the small scale components (in particular so admixtures) are still weighed and added manually because the...