The automated dosing of admixtures in the production of dry premix mortars –

Part 2: Precision dosing equipment

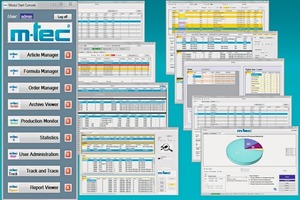

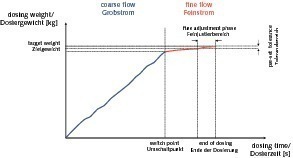

Summary: In Western Europe, dry premix mortar plants operating on an industrial scale are now practically entirely automated in terms of the major raw components and their further processing. However, even here most of the small scale components (in particular additives, pigments and fibres) are still weighed and added manually. This results in a considerable limitation in productivity, efficiency and flexibility regarding the processing of orders, with an increasing risk of variations in the quality of the final product, caused by so-called “human error”. Whilst part 1 explains the theoretical background in brief, part 2 focusses on the new developments to overcome the aforementioned problems by means of the most reliable and affordable systems for fully automated dosing of admixtures.

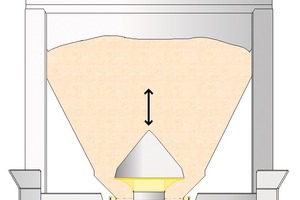

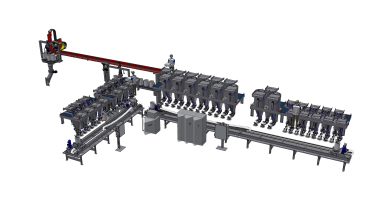

In Western Europe, factory-made dry premix mortars have almost completely replaced site mixed mortar for nearly every single professional application. The newly industrialised countries of Southeast Asia, such as Thailand and Indonesia, are catching up quickly, and also here dry premix mortars delivered to site in transportable silos are becoming common on building sites. Nevertheless, although dry premix mortar plants operating on an industrial scale are now practically entirely automated in terms of the major raw components and their further processing (Fig. 1), most of the...