Producing dry premix mortars on an industrial scale – solutions for newly industrialised countries

Large production volumes with automated mixing tower plants

Dry premix mortars are becoming a common sight on building sites not only in the Western hemisphere. In Thailand, contractors may even be excluded from bidding on construction projects if not delivering dry premix mortar to site in transportable silos rather than as bagged material. China, commonly known for labour-intensive processing, is to ban site mix from building sites, starting in 19 major cities in 2007 already.

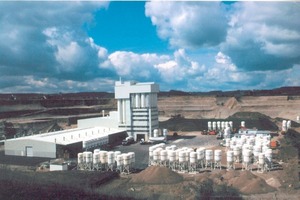

Automated mixing tower plants (Fig. 1) are designed for large production volumes on a very competitive industrial scale. The dosing/weighing equipment and the mixer are located one below the other, allowing processing by gravity. In the slender (basic) version, a mixing tower plant consists of a core tower construction with four major component silos, and a number of smaller additive silos if required. A quite normal size for a mid-size mixing tower plant, capable to produce standard mortars, features 6 to 8 raw material silos, and up to 8 small silos for additives [1]. The storage silos for raw material are fed either pneumatically (by road tankers), or mechanically.

With mechanical conveying, the sands are split into fractions by an upstream screening machine on the top level. Depending on the number of major component silos, either one or two scales are usually fed in parallel from the silos by metering units (dosing screw conveyors and dosing slide valves). The components are passed gravimetrically on to the mixer, with additives and pigments added by special stationary additive dosing systems [2]. After the specified mixing time has elapsed, the mixer empties gravimetrically into the downstream packing process.

Simplified plant concepts for smaller budgets

However, in newly industrialized countries, the processing of site mixed mortar is still very common, despite poor results with respect to quality of processing and durability of the processed products. Investors entering this market are walking a thin line between keeping initial investment on a low scale, but on the other hand not having to completely refurbish their equipment after a short period of operation due to limited life span. Thus, there in fact is a market for durable European equipment, however on a more budgetary scale. Simplified plant concepts are available for those countries where production of mostly bulk products such as but not limited to masonry mortars and base renders are required to meet the demands of the local market. Taking into consideration the vast amount of mortar required in India in the coming years, reliable plants of applicable size, however tailor-made to concentrating on bulk products could be a solution also for the thriving Indian

market

India – a way in the middle

In India, fully automated plants for producing dry premix mortar are not widely spread yet. Consequently, these products are commonly not available everywhere. However, dry premix compounds (i.a. a tailor-made blend of binders and additives) are available, allowing the production of various mortar products for manual and mechanical application on site, if the right site equipment is available. Taking into consideration the local mentality and site conditions, m-tec came up with the co-mix, a job site system for continuous dosing, mixing and pumping of dry compounds, aggregates (job site sand) and water in pre-set proportions. Some of the unique advantages are

– automatic production of mortar products with various binder/additive compounds in good, consistent quality for both, manual and mechanical application

– no sand-drying required (job site sand will do)

– easy transport to site due to compact design, and modular set-up

Afore named premix compounds could be produced locally even in compact mixing plants. These plants are designed for small production volumes (usually for bagged products) and are suitable for semi-automatic operation as well as for fully automatic operation. Due to the modular design, the plant can be confined to the mixer itself in the initial construction stage, while the dosing and weighing is carried out manually. Given an automatic configuration, silo-stored raw materials are fed by means of inclined dosing screw conveyors into a weighing hopper located above the mixer. Additives and pigments are usually weighed out manually and fed into the mixer via manual feed. However, if considered necessary, the plant can be extended to include automatic dosing of additives and pigments as well. In summary, their small space requirements and low capital investment costs in the first stage of production mean that compact plants are ideally suited for the production of products on a small scale and can be automated in stages to meet increasing demands.