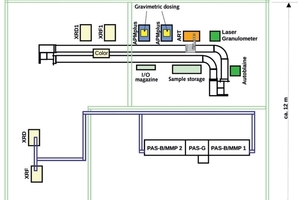

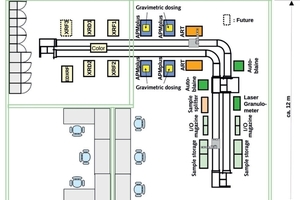

The latest laboratory automation generation at Holcim’s Lägerdorf plant

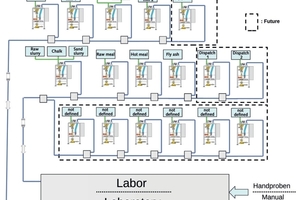

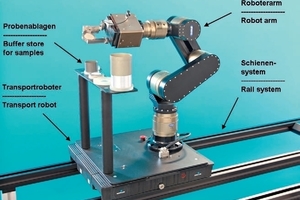

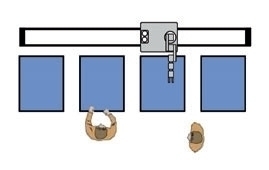

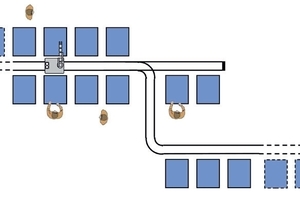

The increasing use of substitute fuels and substitute raw materials in the cement manufacturing process makes it essential to achieve prompt quality data acquisition within the framework of process and production control. At Holcim’s Lägerdorf plant the laboratory automation system is an indispensable quality monitoring tool. The new POLAB® Shuttle generation is designed to assure extremely high availability. Sample conveyance by mobile robot opens up totally new degrees of freedom for the laboratory layout planning. The innovative safety concept makes the laboratory automation system a shared...