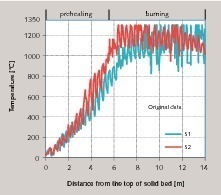

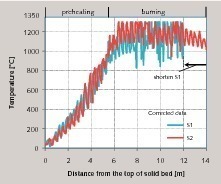

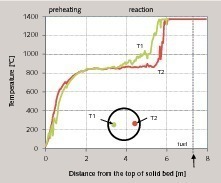

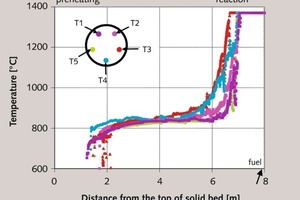

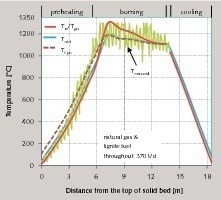

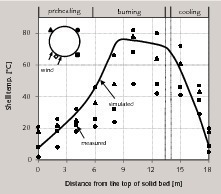

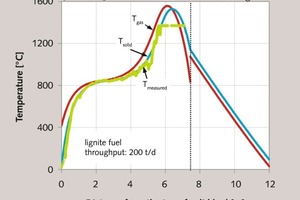

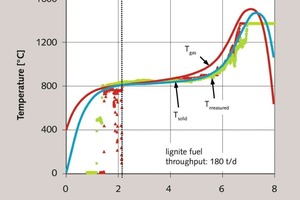

Temperature profiles in the axial direction of one industrial PFR kiln and two RCE kilns were measured using thermocouples. The results show that the temperatures in the PFR kiln fluctuate with differences of about 100-300 °C, since the kiln is operated with two distinct modes of operations (burning and non-burning). The maximum temperatures measured are observed with an average value of about 1200 °C. In the burning zone of the two RCE kilns the temperatures are above the permissible temperature of 1370 °C of the type K-thermocouples.

In all cases, there is a significant temperature...

TEXT �M. Sc. Duc HaiDo1, Prof. Dr.-Ing. Eckehard Specht1, Dr.-Ing. Georg Kehse2, Dr. Olaf Schmidt3, Dipl.-Ing. Steffen Frank4

1 �Otto von Guericke University Magdeburg/Germany

2 �Ingenieurbüro für Wärme- und Prozesstechnik GmbH, Neuss/Germany

3 �Institut für Kalk und Mörtelforschung, Köln/Germany

4 �Fels-Werke GmbH, Rübeland/Germany