1 Introduction

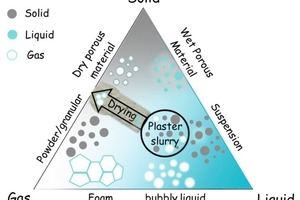

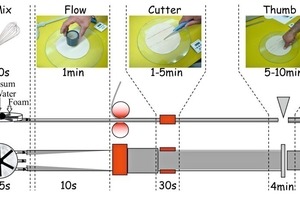

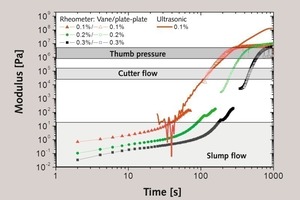

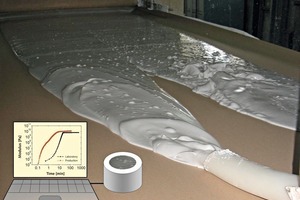

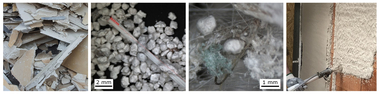

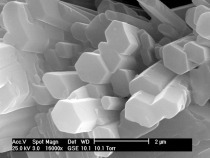

Gypsum based binders are widely used in construction. Combined with water and air, there are a huge variety of cost-competitive products which can be poured, sprayed or extruded to follow the desired forms for field or plant production. The apparent simplicity of gypsum chemistry is faced with complex technical production processes which are influenced i.e. by fluctuating gypsum raw material qualities and different calcining methods. Additionally, the complexity of the crystal structure formed depends on the hydration process as well as external parameters such as temperature and...

TEXT Dr. Didier Lootens, Maria Ampudia, Dr. Christina Hampel and Dr. Markus Mueller* Sika Technology AG, *Sika Services AG, Zurich/Switzerland