1 Introduction

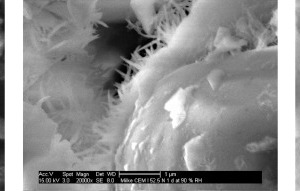

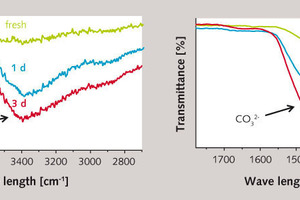

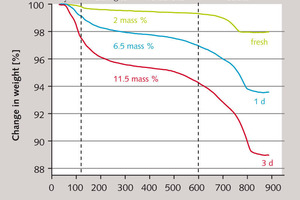

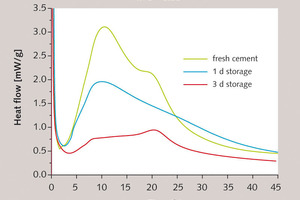

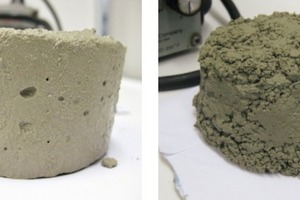

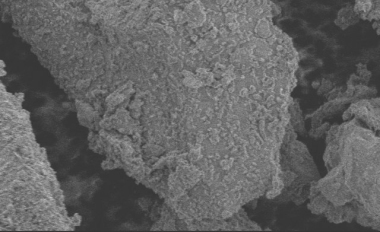

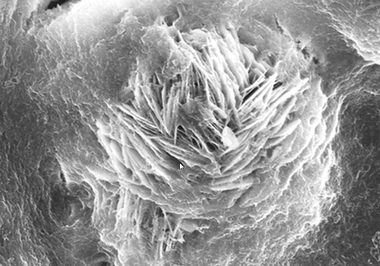

Cement may be affected by moisture and become slightly hydrated on the surface due to sorption of water both during production and during transport and subsequent storage in contact with atmospheric humidity [1 – 4]. Water vapour and possibly also CO2 react with the surface of the cement particles. The surface hydration may even begin during the production in the cement plant, e.g. as a consequence of the dehydration of gypsum during the grinding process in the cement mill. Some cement producers also spray up to 2 % water into the clinker mill in order to keep the temperature...

TEXT Elina Dubina, Prof. Dr. Johann Plank*, Chair for Construction Chemicals, Technische Universität München, Garching/Germany

* corresponding author: sekretariat@bauchemie.ch.tum.de (Johann Plank)