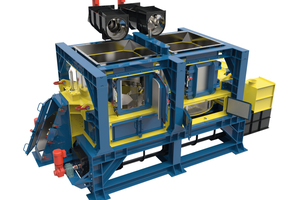

A TEC Rocket Mill installation at RDF production plant in Austria

To optimize the production of highly caloric residue-derived fuels for the cement industry the Austrian company .A.S.A. will install A TEC’s Rocket Mill in their treatment plant in Wiener Neustadt/Austria. After an erection time of six months the future fuel products will be supplied with an output size of max. 15 mm, 50 % < 5 mm (depending on the material) and can be easily adapted to the optimum size for the client’s pyro-process. Mainly produced by A TEC Plant Construction in Eberstein/Austria the mill will have a capacity of 7-9 t/h and is going to be put into operation in August 2016.

The A TEC Rocket Mill is an innovation for alternative fuel preparation which combines drying and grinding in one step. The machine is equipped with two grinding chambers which can be independently loaded. Permanent control of the mill power guarantees optimum and secure utilization. The input material usually only requires one pre-shredding step followed by a sieving step, which is sorting out the organic and magnetic separation.

Interchangeable perforated screens will adapt the size of the final product to the optimum for the customer’s pyro-process. Due to the grinding technology, a drying effect of approx. 10 % is given. Additional drying with process waste gas is possible to achieve a higher drying rate. The ultra-fines are dedusted and also dosed to the kiln system.

//www.atec-ltd.com" target="_blank" >www.atec-ltd.com:www.atec-ltd.com