Airflow with cost-saving potential

The cement plant belonging to the Volan Cement Plant Group in Inner Mongolia has changed over the blowers of three of its production lines to variable-speed operation. The result: By using frequency converters, the electrical energy consumed was reduced on average by 36 % with respect to the previously-used throttle controls. Furthermore, variable speed operation reduces the load and stress on the plant mechanical system and ensures a more precise process control. As the drive systems can be connected to an energy management system, the retrofit to variable-speed operation resulted in additional decisive energy-saving potential that opens up new market opportunities for the operating company.

1 Introduction

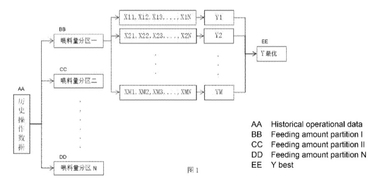

The factory belonging to the Volan Cement Plant Group, located approx. 100 km from the city of Jining in Inner Mongolia has four production lines and produces a total of 10 500 t/d of cement. The factory that went into operation in 2000 set itself a goal to reduce its overall consumption by 20 %. It was already quite clear that special emphasis would have to be placed on the drive technology as it consumes the largest percentage of the electrical power of a cement plant (Fig. 1). The drives of fluid flow machines – such as pumps or fans with square-law load characteristic (M ~ n²) – were considered to be the highest energy consumers. In a cement plant, these are predominantly the blowers for the kiln, coolers and mills (Fig. 2).

2 Variable-speed operation represents

the highest potential

This is the reason that personnel from Siemens Industry Automation Ltd., Shanghai quickly defined the most effective measure. Instead of regulating the airflow using mechanical throttles, which were used up to the present, this was now to be effected by changing the motor speed using a frequency converter. For example, with mechanical control principles such as throttle valves, the fan motor always operates at full speed. This means that it continually draws the rated power, which is dimensioned for the maximum flow rate, from the line supply. The airflow is reduced according to the demand using mechanical throttles. The amount of energy wasted is the difference between the actual flow rate and the maximum possible flow rate.

On the other hand, with a frequency converter, the motor speed is always precisely adapted to the currently required flow rate. This means that only the power actually required is drawn. The payback time for a frequency converter is often just a few months as a result of the cost savings that are achieved.

3 Energy savings of more than a third

This is the reason that the Volan Cement Plant Group awarded Siemens an order to upgrade the blower motors of the coolers of its production lines to variable-speed operation using frequency converters. After the retrofit, the company carried out an online energy saving analysis for 168 hours in order to quantify the cost saving effect (Figs. 3– 4). The results were extremely positive: For production line 1 with a total of 7 motors, an energy saving of 37.12 % was obtained, for production line 2 with a total of 5 motors, it was 33.75 % and for production line 3 with a total of 4 motors, the energy saving was 37.44 %. This meant that overall, the energy consumption of the production lines was reduced by approximately 36 % (35.78 %).

However, variable-speed operation using frequency converters brings with it additional advantages. The throttles that were previously used to regulate the air flow always became worn very quickly due to the fine cement dust. As a consequence, they have to be continually serviced or replaced. The new frequency converters also eliminate this cost factor. Furthermore, converter-based variable-speed operation eliminates the current peaks when accelerating and in turn, the associated torque surges that can be quite significant. The soft starting and stopping also reduces the load and stress on the mechanical system of the complete drive train – and increases its lifetime. Pressure surges, that put considerable stress on the piping system, are now also a thing of the past.

4 Higher-level energy management system n preparation

From all of these positive aspects, as a result of the increasing energy costs, the electrical energy saving potential was certainly one of the most important arguments for variable-speed operation of the blower drives. This is the reason that in a second step Volan will integrate the frequency converters into a higher-level energy management system. Siemens has already prepared the corresponding interfaces (Profibus DP) for this purpose. The energy management system is based on a combination of Siemens concepts – “Totally Integrated Automation” and “Totally Integrated Power” – which include seamless and integrated solutions for automation and power distribution. The central system component is a control platform for the operational energy management. This control platform continually monitors and optimizes the energy flows throughout the complete process. This means that the cement plant can further reduce its energy consumption to improve its overall energy balance even more.

5 Conclusions

Equipping the blowers in the Volan cement plant with frequency converters from Siemens resulted in energy cost savings that were so high when compared to the previous throttle control that the operating costs were significantly reduced. Not only this, variable-speed operation reduces the load and stress on the plant mechanical system and ensures a more precise process control. Furthermore, because the drive systems can be connected to an energy management system, the retrofit results in additional decisive energy saving potential that opens up new market opportunities for the operating company.

www.siemens.com/energiesparen