“Efficiency – what is that?” – How to measure the performance of a kiln line?

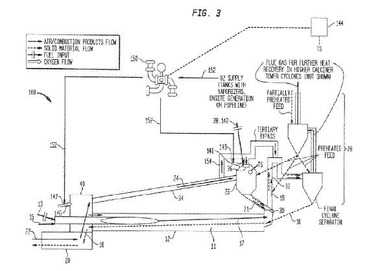

In the past editions I have written in a rather abstract way about “process optimization” time and time again – and you may be asking yourself: what does that mean in a specific case? The question is justified – but let me also ask: What does “optimal” mean in a specific case? How would one measure “optimal operation”? Classically, parameters such as production output or energy consumption will be mentioned here. However, these performance values are not well suited to describe whether a system really runs optimally, because any installed system could easily benefit if reserves are built into its design. How can you assess the performance of the operating personnel and the kiln line without falsifying the assessment due to hidden reserves? Specific parameters or KPI’s are then used to calculate a target value in relation to cost. A classic example is the specific fuel requirement or the specific amount of exhaust gas, which process engineers particularly like to consider. However, these values are also only suitable to a limited extent because they depend heavily on the fuels used and particularly strongly on the raw material moisture of the specific case. The performance and excellence of the operating personnel, as well as the performance of the plant system, is probably best represented by the oxygen content during operation in the kiln inlet chamber and after the preheater. This parameter describes best how close the kiln system is operated “at its optimum” – or in other words: how much the operation of the system exploits the potential of the system technology. Of course, the oxygen values too cannot be compared 1:1 between different kilns, because plant and fuel specifics can be very different. In any case however, high “required” oxygen values are either a sign of the comfort zone of the kiln operation or a sign of the combustion process not working properly. Often coarse fuel falls from the calciner or the kiln riser duct into the kiln inlet, where it reduces oxygen unnoticed in the material bed and thus signals to the system operator either through build-up or quality problems: “We need more oxygen!” If, on the other hand, the fuel were to be kept in suspension, the kiln would also be able to be operated with a lower oxygen supply and would therefore be considerably more energy efficient.