Biomass fuel drying and cement kiln coupled system

(22) 08.02.2023

(43) 28.07.2023

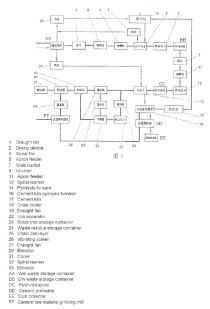

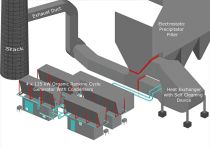

(57) The utility model discloses a biomass fuel drying and cement kiln coupling system and method. The system comprises a grate cooler waste heat recovery system, a kiln cylinder waste heat recovery system and a biomass drying system. The grate cooler waste heat recovery system introduces kiln head waste heat flue gas of a cement kiln into the biomass drying system to dry biomass, the kiln barrel waste heat recovery system exchanges heat between a collected heat medium and the kiln head waste heat flue gas after the biomass is dried and cooled, and the kiln head waste heat flue gas after heat exchange dries the biomass again. And after heat exchange, the waste heat returns to the kiln cylinder waste heat recovery system for cyclic heating. Waste heat of the kiln head of the cement kiln and heat dissipation of the rotary kiln barrel are introduced into the biomass drying system, the waste heat of the cement kiln is utilized, meanwhile, the biomass is subjected to dewatering drying, the heat value of the biomass is increased, and finally the fuel replacement rate of the cement kiln is increased; and the final moisture content of the biomass can reach 10-15%.

(71) Sinoma Int Eng Co Ltd (CN)