Alternative fuels

In his lecture “Characterization of alternative fuels for the co-incineration” Dr. Siegmar Wirtz described impressively the results of a joint project of various partners, among them the companies ThyssenKrupp Polysius and Hitachi, the Fraunhofer Institute UMSICHT, the Bochum Ruhr University and others. The goal was to analyze three alternative fuels in detail and to convert the results into calculation models. Amongst other things, the particle geometries, flight behaviour, resistance coefficients as well as the ignition and incineration properties of the fuels were determined. With these data, simulations of various plants were carried out successfully and close to reality.

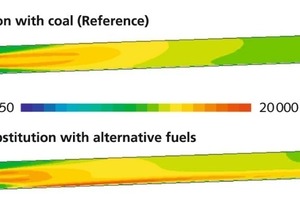

Dr. Martin Ehman showed examples of the “CFD simulation of the co-incineration of alternative fuels in firing systems”. Amongst other things, the successful CFD simulation of alternative fuels is possible by using UDFs (User Defined Functions). However, unknown alternative fuels have to be investigated in fractions. Then the fuel data thus obtained can be converted into UDFs.

Then followed Philipp Danz dealing with the topic “Carefully controlled torrefaction for co-incineration in power plants”. He underlined problems and challenges of the torrefaction of biomass. He said that the goal, i.e. to prepare biomass in such a way that a direct co-incineration and co-grinding is possible, is tangible but has not yet been achieved. The final lecture with the topic “Plant-oriented adaptation of alternative fuels” was given by Burkhard Krüger. He presented the project “iFuel”, which aims to develop a made-to-measure alternative fuel for the clinker production in a relatively short rotary kiln. His conclusion is that the manufacture of particularly adapted alternative fuels is possible. However, it is necessary to extend the analyses as regards the thermal conversion and the flight behaviour as well as to expand the model for a complete representation within the framework of simulations.

For the 50 participants it was a very informative and industrially comprehensive event with a lot of new impressions. Biomasses and alternative fuels and their characterization will remain a topic of research and application also in the future. For further information see: