Alternative fuels in the cement manufacturing process

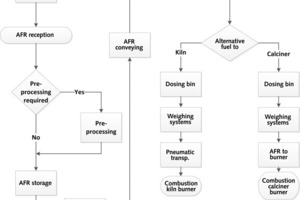

Due to the numerous possible sources of alternative fuels, the degree of variability in energy content, ash, moisture, particle size, form, density etc., extensive experience and know-how are necessary in order to identify the effect of co-processing on the clinker production process and, thus, offer the best solutions for the entire application of alternative fuels in the pyroprocess, comprising of the handling and firing systems.

1 Effects on the clinker manufacturing process

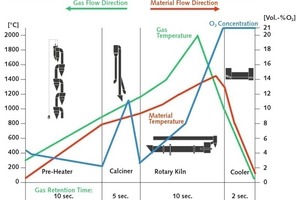

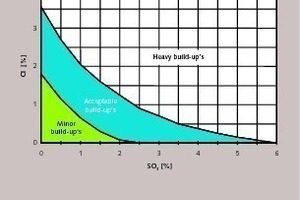

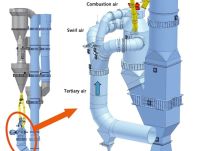

The clinker manufacturing process offers ideal prerequisites for the safe combustion of alternative fuels. Due to the fact that the process involves high temperatures, long retention times, and high oxygen concentrations (Fig. 1) complete conversion of the organic substances is assured. Lime, the main raw material component, produces a basic dust atmosphere which assures safe transformation of the acid elements introduced with the alternative fuels, such as chlorine, sulphur and fluorine, from the gas phase into the solid phase. The mineral...