Alternative inorganic rheology modifier

Drymix systems are manufactured for various applications such as tile adhesive, joint grouts, renderings (gypsum and cementitious), EIFS, repair mortars and masonry mortars. This diversity requires the use of specially formulated products. Precise adjustment of the rheological properties enables the use of dry mix systems for a wide variety of applications and application methods.

The use of rheological active agents, ensures control of parameters like workability, sagging control, pumpability and resulting surface quality. In addition, to adjust properties, rheological active agents should have no adverse impact on important properties; if possible these parameters should be positively influenced:

water demand

open time

correction time (tile adhesives)

set retardation

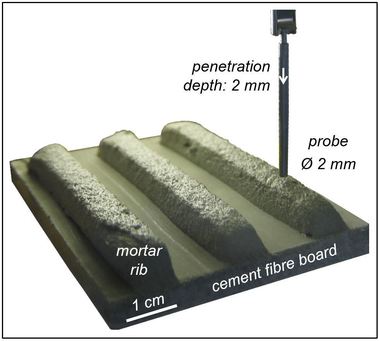

wet adhesion to substrates

adhesion in the cured state

durability of contact materials

bleeding

water resistance

steam permeability

freeze/thaw resistance

crack bridging or prevention

Wollatrop, now available for use in drymix mortars, is an innovative inorganic silicate-based rheology modifier agent for aqueous systems. It allows adjustment and therefore optimisation of workability, wet adhesion to substrates and adhesion to surface in the hardened state, sag resistance, pumpability, and final surface finish without the development of cracks or bleeding.

The use of adequate amounts Wollatrop, does not affect open time, durability, setting properties, correction time, water demand, water resistance or heat resistance.

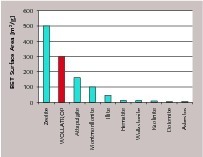

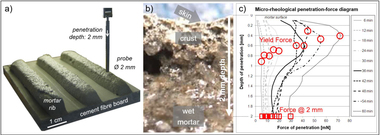

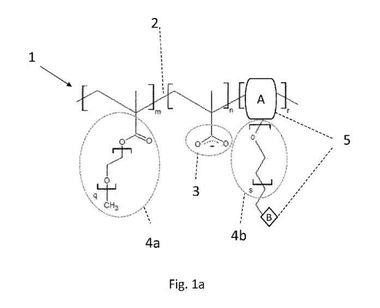

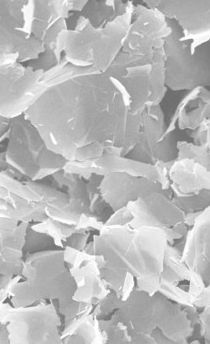

The rheological effect of Wollatrop is based on the enormous large surface area (Fig. 1), in conjunction with structure and chemical composition. The high concentration of Si-OH groups on the surface, allows thixotropy causing interaction with organic and inorganic formulation components.

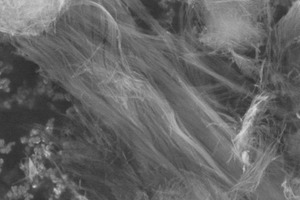

A further advantage is the easy incorporation into drymix systems. Wollatrop disperse easily in water (Fig. 2) thereby it is a safe-to-use, inorganic economical alternative to control the rheological properties. The low cation exchange capacity ensures over a wide pH range (3-14) stable and efficient control of rheology.

Wollatrop is classified as group 3 product by the IARC and therefore to be regarded as a safe product. Unlike organic thickeners, it requires no preservatives.

Depending on the desired rheological effect Wollatrop can be used alone or in combination with a traditional rheology modifier for example cellulosic ether. When used alone, like in pumping mortars the recommended Wollatrop quantity is between 1 % and 1.5 %. For tile adhesives 20 to 30 % of traditional cellulosic thickener can be replaced in a ratio of 2:1 (Wollatrop : Cellulosic ether).

//www.osthoffomegagroup.com" target="_blank" >www.osthoffomegagroup.com:www.osthoffomegagroup.com