Skin and crust formation at mortar surfaces – mechanisms and influencing factors (Part 2)

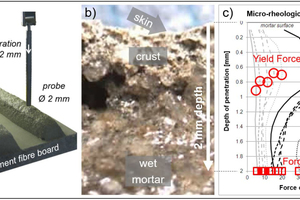

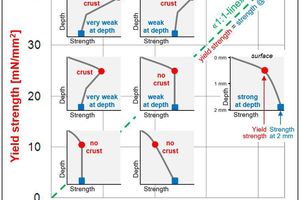

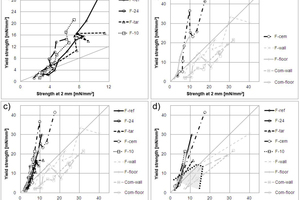

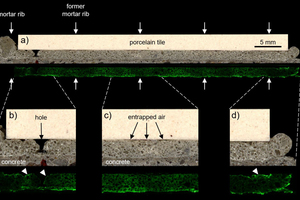

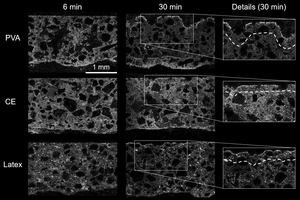

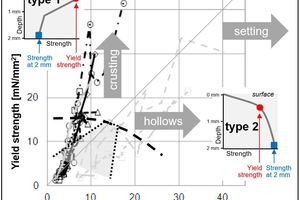

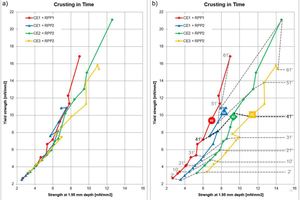

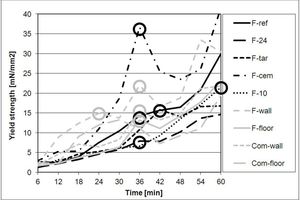

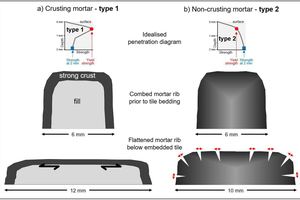

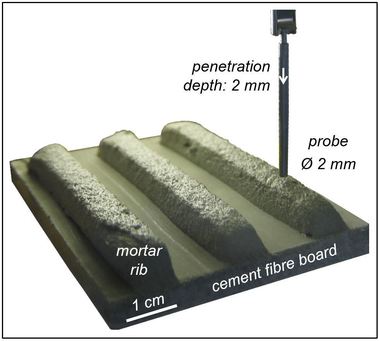

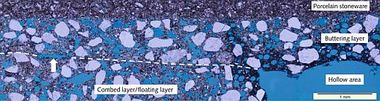

Cementitious mortar layers have a high surface-volume ratio and their evolution is influenced by intrinsic formulation parameters and extrinsic environmental parameters. The latter often cause an early drying of the mortar surface while deeper mortar parts are still wet and soft. This dry surface is called skin and crust, respectively, when thinner than 0.1 mm and having a thickness of ~0.5 mm. Investigation by a newly developed micro-rheology method make it possible to follow the buildup of a crust during the first hour after mortar application. The crust is growing in thickness and reaches a critical strength between 10 and 15 mN/mm2. When stronger, the crust will no longer break during embedding of the tile. As a result, the tile is not properly wetted by fresh mortar and adhesion strength is below 0.5 MPa. According to EN1346 in this case the tile adhesive has lost its open time performance. Laser-scanning microscopy of hardened mortars containing cellulose ether, polyvinyl alcohol and redispersible polymer powders, which were stained by fluorescein, indicate that these organic additives can be enriched in a thin skin. Our observations reveal that additive enrichment as a mechanism to build up a 0.5 – 1.0 mm thick crust can be excluded. Conclusively, crusting is mainly driven by a drying front which first affects the surface and then retreats into the mortar. The study reveals a second mechanism which limits the open time performance. Instead of forming a crust, a mortar rib can thicken uniformly across its entire volume. But when the mortar becomes stronger than 20 mN/mm2, then the tile embedding pressure is too low to press the combed mortar ribs completely and hollows remain in between the ribs.

1 Introduction

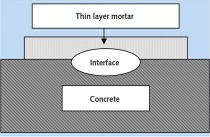

Mortars are applied in relatively thin layers, which are exposed to substrate and air. Thus, environmental parameters have a strong influence onto the development of an applied mortar layer from the first moment of application and during the following curing time. Long before the material starts to set, the surface of the applied mortar layer starts to dry and changes its properties, such as the wetting capability. In the case of a ceramic tile adhesive the loss in wettability is crucial for the resulting adhesion properties.

The European Standard EN 1346 (note that in 2017 EN...