Application of new types of retarders in improving the properties of FGD gypsum

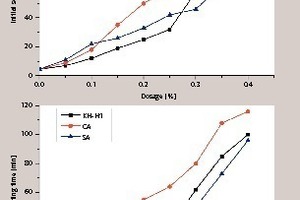

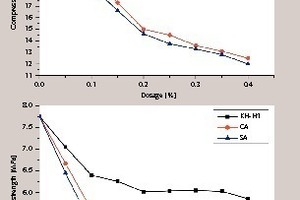

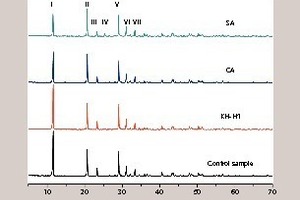

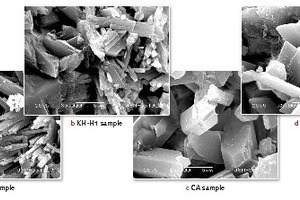

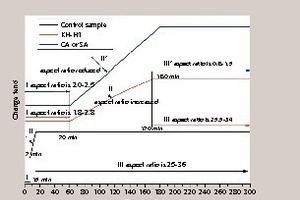

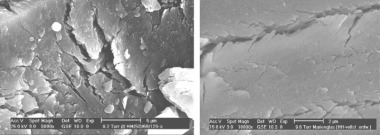

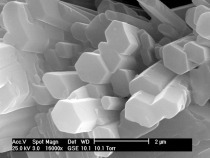

Flue-gas desulfurization (FGD) gypsum is a solid by-product from the exhaust of coal fired plants. Due to the low price and abundant availability of FGD gypsum, the material has a good potential for application in building materials after calcination to ß-calcium sulfate hemihydrate (ß-HH). However, the very short setting time of this binder system becomes a problem. In this paper, experiments with different retarders showing influences on setting and hardening processes are examined. The effects on setting time, crystal size, morphology and its solution-precipitation processes are detectable by X-Ray Diffraction (XRD), scanning electron microscope (SEM) and a digital microscope.

1 Introduction

China is a developing country with coal as its main energy resource. The energy infrastructure is dominated by the coal fired power industry. Taking 2012 as an example, the yield of coal in China was 3.65 billion tons [1]. In contrast, its consumption was about 4 billion tons. The entire emission of SO2 in China was 21 176 million tons, among which more than 20 million tons was due to the combustion of coal and more than 50 % was generated from thermal power plants [2-3]. It is estimated that by 2020, the coal yield in China is going to rise to 4.8-5.3 billion tons [4], so the...