Burner supplier backs innovative measuring technology

An example from the cement industry is examined to illustrate the combination of a burner with Endress+Hauser’s Promass I mass flowmeter, which applies the Coriolis principle. This permits not only acquisition of the classical Coriolis variables, such as mass flow, fluid density and temperature, but also quantification of the conveyed fluid’s viscosity.

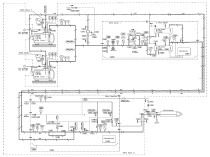

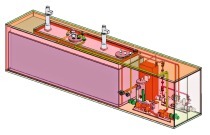

Glycerine byproduct from bio-diesel plants is used in a cement plant in Austria as a substitute fuel. This glycerine contains residual amounts of methanol, due to the production process. The fuel is stored in two horizontal tanks, which are equipped with hot-water heating. The pump installed adjacent to these tanks delivers the glycerine, heated to 30 to 50° C, firstly to a preheater and then to the burner of the calciner in the preheater tower. The more than 160 m long delivery line is fitted with trace heating. This combustion system was supplied by Unitherm Cemcon, of Vienna.