Bypass system at LafargeHolcim Kujawy will be upgraded by A TEC

To reduce the chlorine contents without causing substantial thermal losses in the kiln line LafargeHolcim has awarded A TEC a contract for upgrading its existing Reduchlor bypass in Kujawy/Poland. Based on detailed computational fluid dynamics (cfd) and process simulations the existing bypass rate will be increased from 5 to 10 %. This increase of the bypass rate has been realized under the precondition of keeping the existing main equipment of the bypass such as the bypass filter and bypass filter fan. The project will be commissioned in spring 2017.

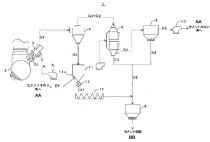

Modern suspension preheater kilns frequently face substantial problems of coating by dust deposition in kiln riser ducts, meal pipes, ducts and cyclones due to excessive contents of Chlorine (Cl) in the kiln system. A TEC’s bypass Reduchlor consists basically of a take-off chamber above the kiln inlet, specifically designed for each installation and a specially designed quenching chamber where the Cl condensates on and adheres to the fine dust particles. After this condensation process the Cl-enriched material is collected in a filter.

//www.atec-ltd.com" target="_blank" >www.atec-ltd.com:www.atec-ltd.com