Chlorine bypass system and method for removing chlorine from cement kiln exhaust

(22) 24.10.2014

(43) 21.05.2015

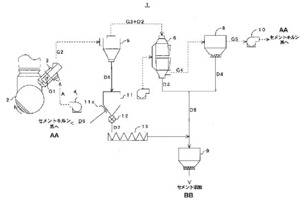

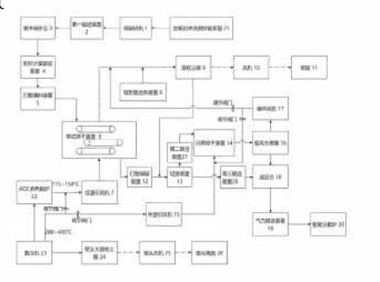

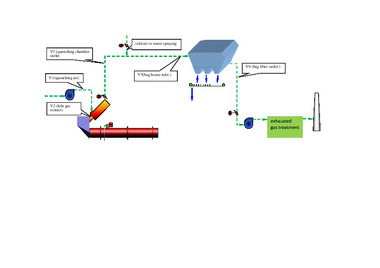

(57) This chlorine bypass system (1) is provided with: a probe (3) which extracts a portion (G1) of combustion exhaust gas from a kiln exhaust gas flow path leading from the bottom of a cement kiln (2) to a cyclone in the lowermost stage of a preheater; a classification device (5) which separates the gas extracted by the probe into coarse powder (D1), fine powder (D2) and gas (G3); and a distribution device (comprising a storage tank (11) to a screw conveyor (13)) which distributes the coarse powder separated by the classification device to a route for return to the firing system of the cement kiln and a route for discharge from the firing system of the cement kiln. The coarse powder can be distributed at any ratio into these two routes. A dust collection device (8) is provided which recovers fine powder from the fine powder and gas separated by the classification device, and optionally, the coarse powder (D7) distributed to the route for discharge from the firing system of the cement kiln may be merged with the fine powder (D4) recovered by the dust collection device (and fine powder (D3) recovered from a cooler (6)).

(71) Taiheiyo Engineering Corporation, Tokyo (JP)

(84) ARIPO (BW GH GM KE LR MW MZ NA RW SD SL SZ TZ UG ZM ZW), Eurasian (AM AZ BY KG KZ RU TJ TM), European (AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR), OAPI (BF BJ CF CG CI CM GA GN GQ GW KM ML NE SN TD TG)