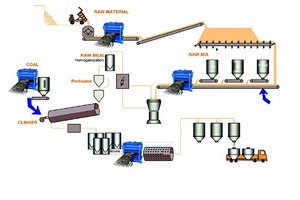

CNA in the quarry – problems and solutions

Operational stability remains a key objective in any plant performance. On the way to

achieving this goal, there are many obstacles to be overcome – from raw materials to production processes and technical equipment. At the starting point, quality control is essential as disturbances will “echo” throughout the process making smooth and efficient operations impossible.

1 Introduction

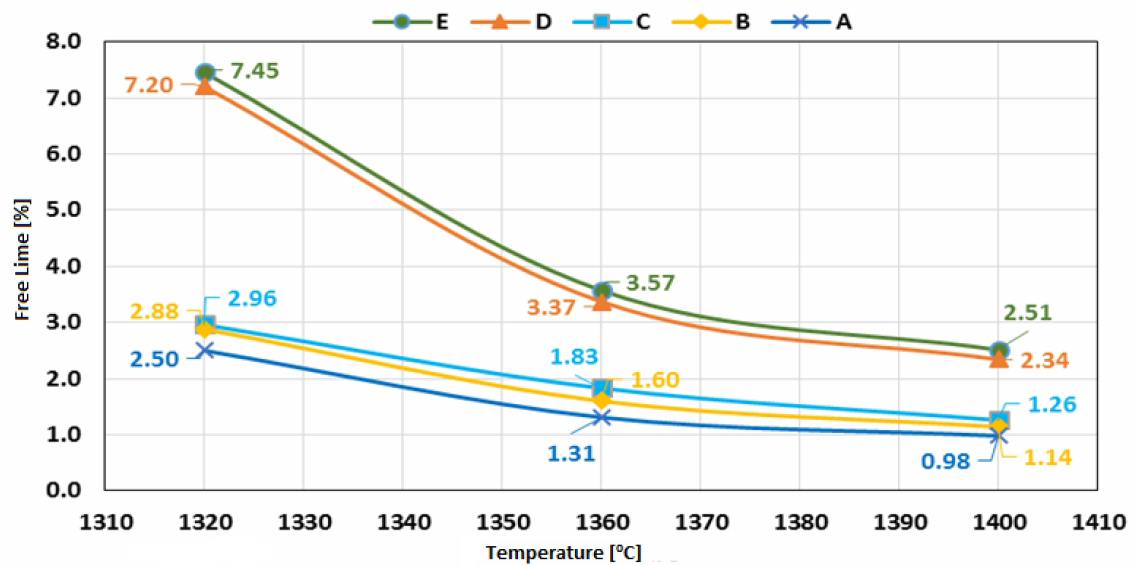

The cement industry continues to develop the cement making process in order to produce cement in a “better” way. “Better” covers a wide range of parameters from production cost, cement quality, cement properties and of course environmental impact. While there have been many new and exciting developments in these areas, many of the challenges of controlling the cement process remain unchanged from the early days of the industry.

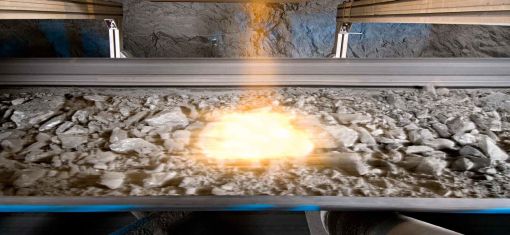

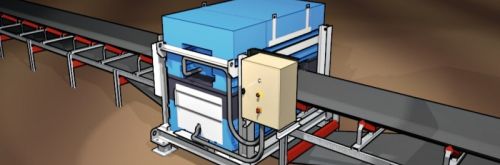

Operational stability remains a key objective and standing in the way of this goal are many causes of variation and malfunctions. The raw materials,...