Cooler

(22) 22.02.2019

(43) 06.09.2019

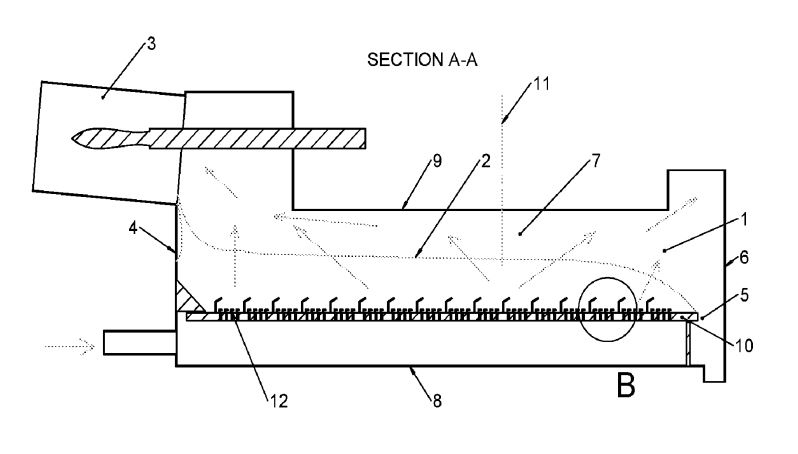

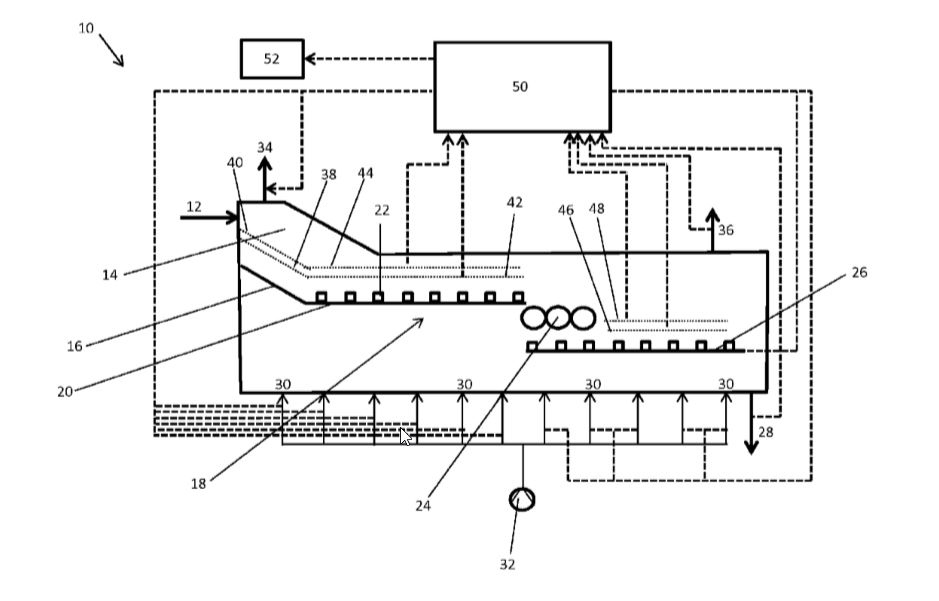

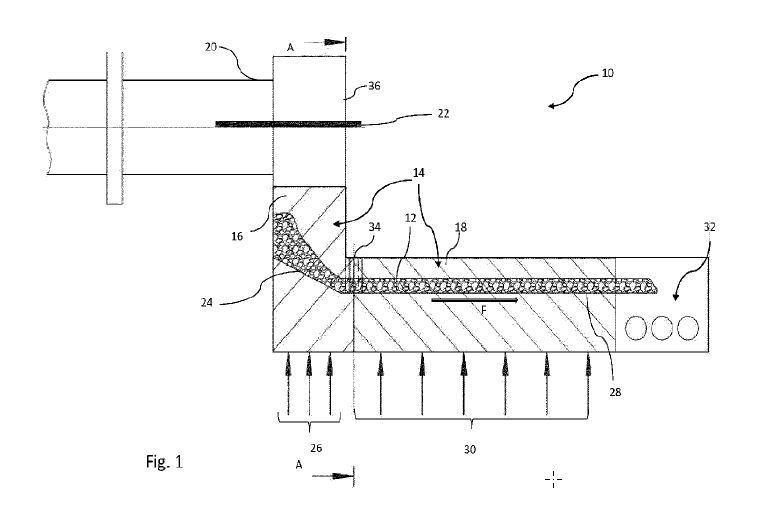

(57) The present invention relates to a cooler for cooling particulate material which has been subjected to heat treatment in an industrial kiln, such as a rotary kiln for manufacturing cement clinker. This cooler comprises an inlet, an outlet, end wall, side walls, a bottom and a ceiling, at least three reciprocating supporting lanes for receiving, supporting and transporting the material to be cooled, the lanes are moving following the walking floor principles as well as means for injecting cooling gas into the material through grate plates in the lanes. The present invention relates to an increasing in the vertical shearing height, and still having stationary clinker on top of the grate plates, see fig. 5. The length of the tilted element (16) is L and the distance (13) between two devices is G. The angle between the element (16) and horizontal is alfa (18). Since the air is distributed evenly from the full grate plate area it is obvious and understandable that the L*cosines(alfa) becomes a shadow area where all air from the region in the grate plate will go through the stationary clinker and leave the tip of L at this one point only. Again, it is not good for the heat recuperation to have a shadow area too big – as it, again, gives an uneven air flow through the clinker bed, damaging the heat recuperation. The vertical shearing height is on the other hand L*sinus(alfa). But if alfa becomes too large (approximately above 60 deg.), it will block the sliding effect, as now the clinker will not get forced over the plate’s L-part, and then the wished larger vertical shearing is not achieved. It is hereby a compromise to get a certain vertical shearing: L*sinus(alfa) by not having a too large shadow area L*cosines(alfa), but still having the angle alfa so low that the clinker will slide at L – see fig. 5.

(71) Føns Companies ApS, Glenstrup Søvej 1, 8990 Faarup (DK)