Effect of nano-TiO2 on the hydration and hardening of fly ash/cement systems

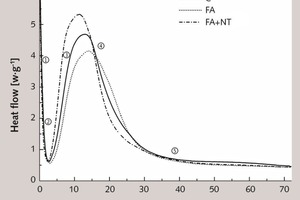

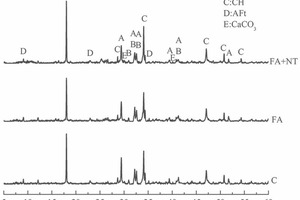

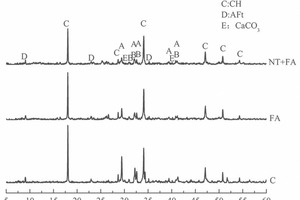

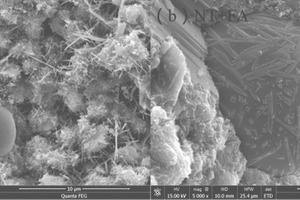

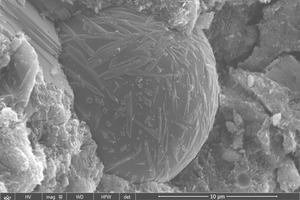

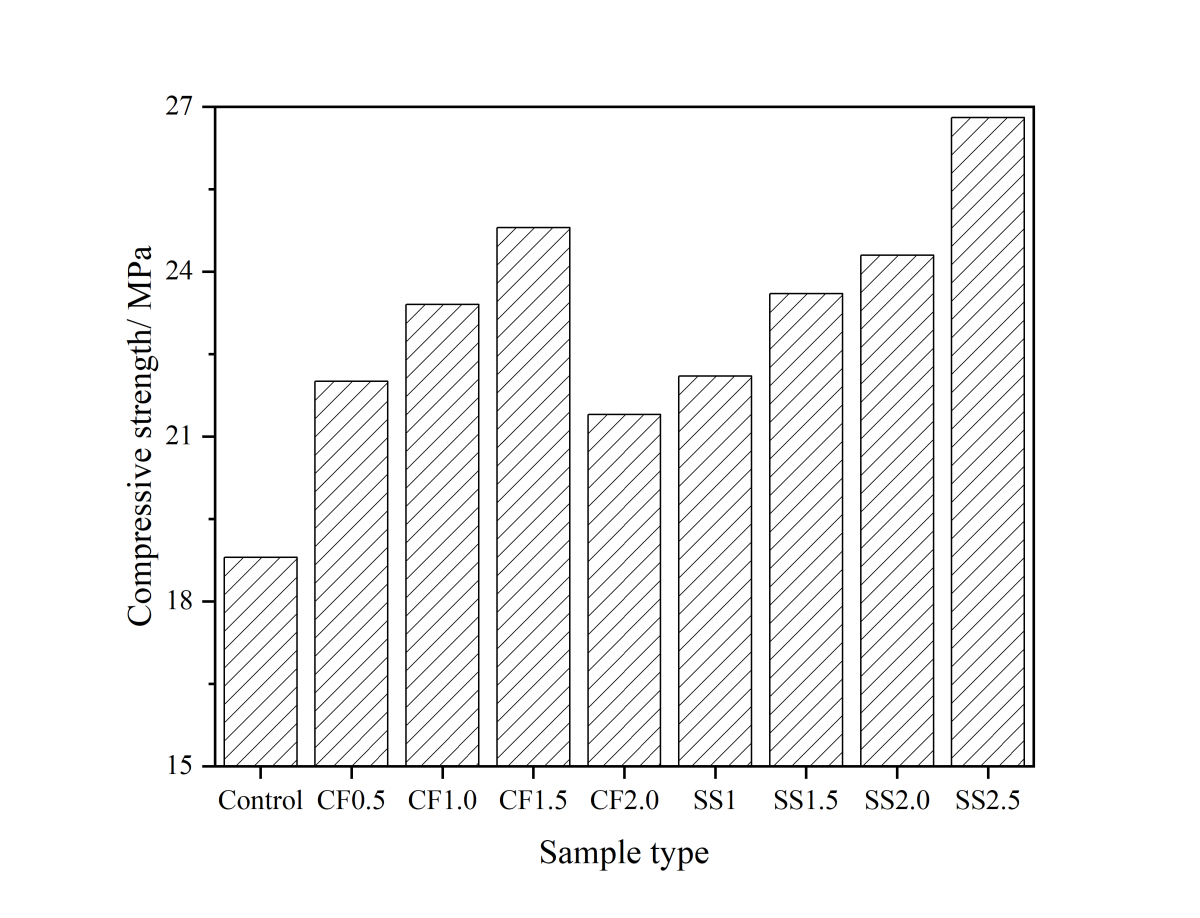

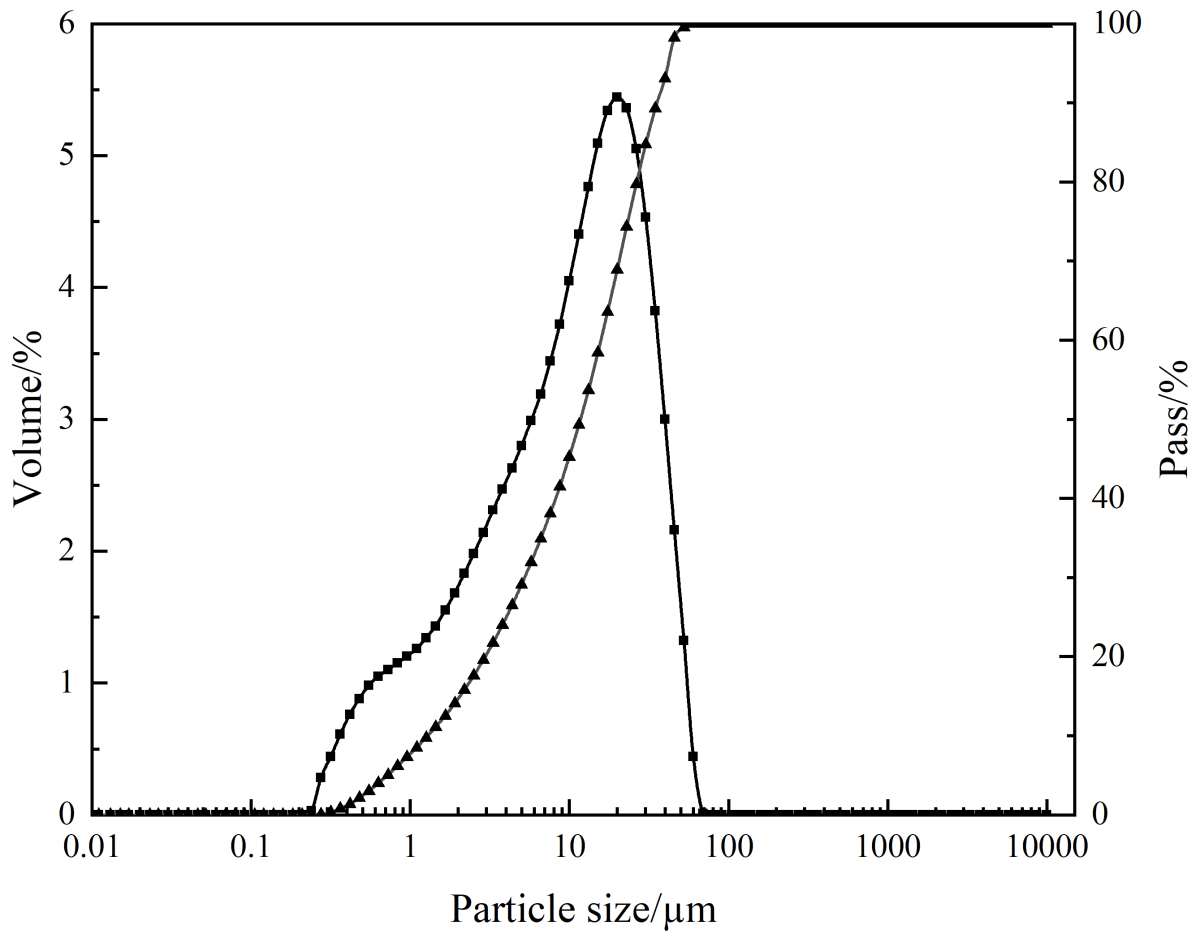

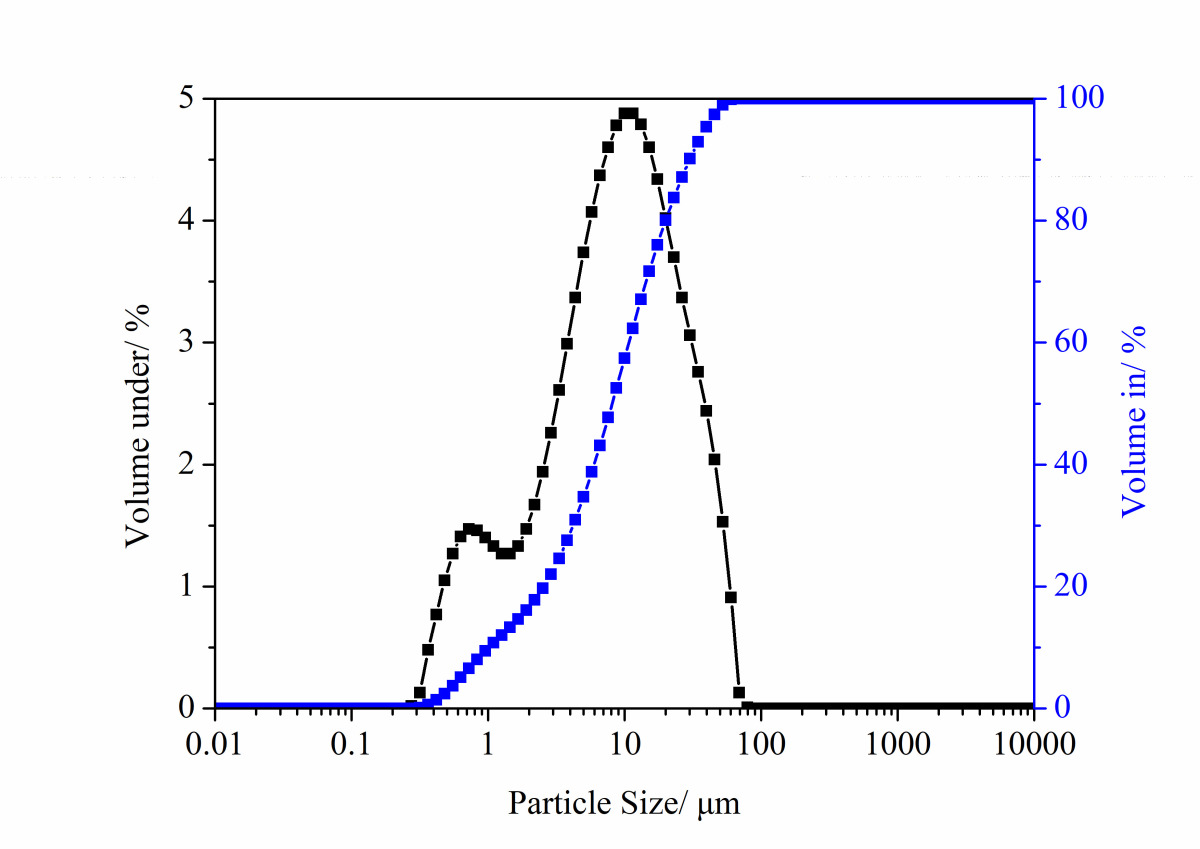

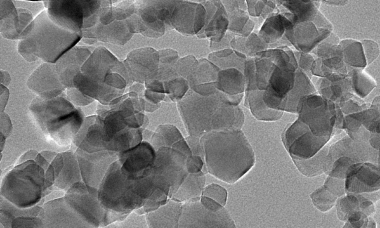

Microthermal analysis, X-ray diffraction (XRD), differential scanning calorimetry (DSC), scanning electron microscopy (SEM) and mercury intrusion porosimetry (MIP) were used to study the hydration and hardening of fly ash/cement systems containing 5 wt. % nano-TiO2. Research found that the heterogeneous nucleus effect caused by the high surface activity of nano-TiO2 can promote the hydration, increase the exothermic rate of hydration at early ages and accelerate the pace of the secondary hydration reactions of fly ash. In addition to the micro-aggregate effect of nanoparticles, the total porosity was decreased, harmless pores were increased, and the microstructure of hardened cement paste became more homogeneous and denser. The addition of nano-TiO2 can also increase the water requirement to achieve standard consistency, shorten the setting time and enhance the compressive strength development of fly ash/cement systems.

1 Introduction

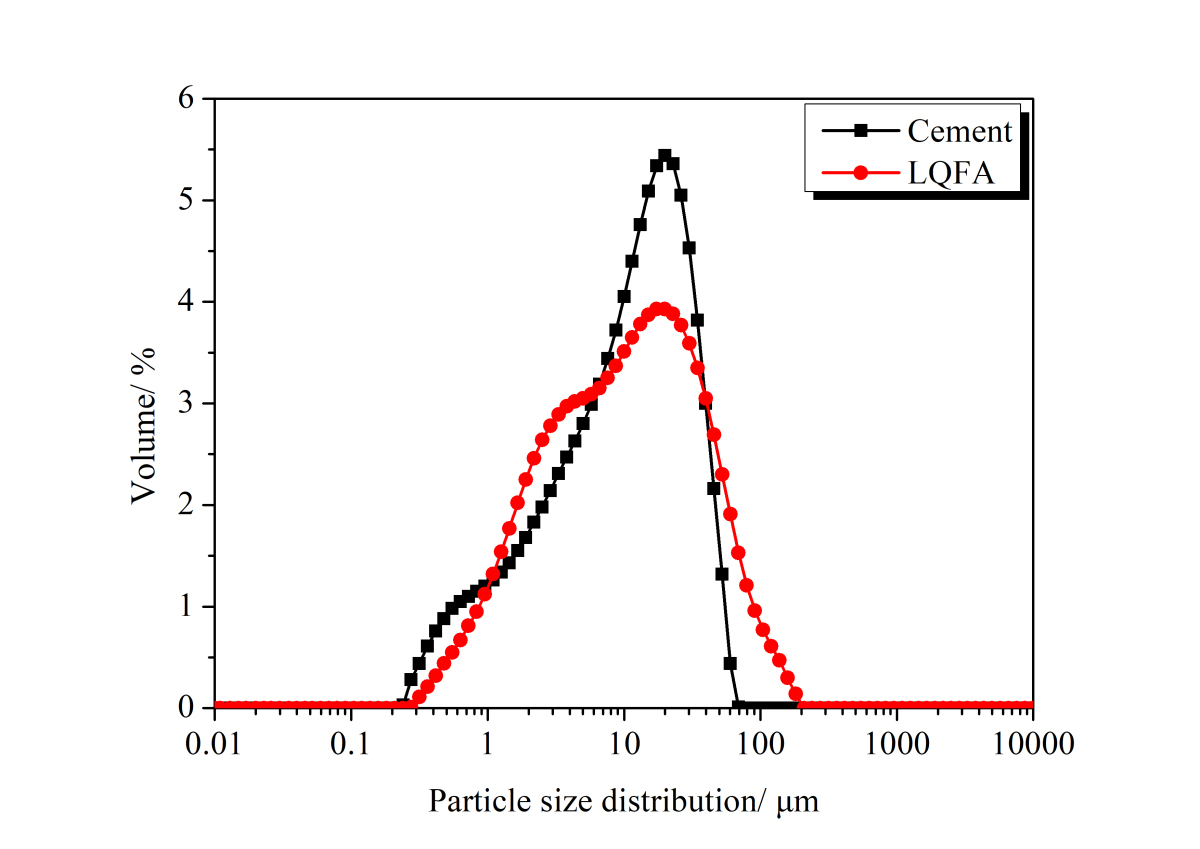

Fly ash (FA) has the advantages of improving the workability [1], decreasing the porosity and increasing the late strength and durability [2-4] of cement-based materials. However, the early strength of FA-cement-based material develops slowly, which is a disadvantage for its practical application [5, 6]. Nanomaterials with high surface activity have the ability not only to fill the spaces between C–S–H gels particles to improve the density of the matrix, but also to act as nucleation sites for the early cement hydration, all of which will help to enhance the early strength of...