Effect of raw material components on RDF pyrolysis gas products

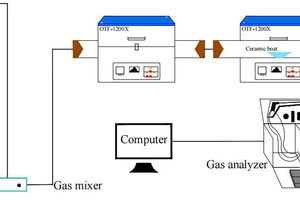

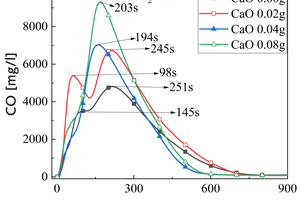

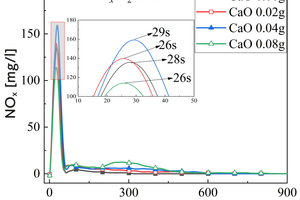

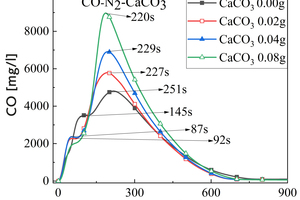

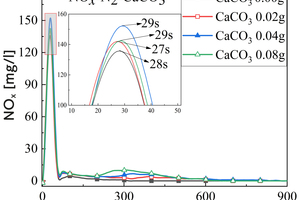

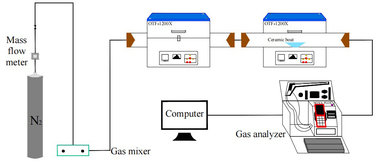

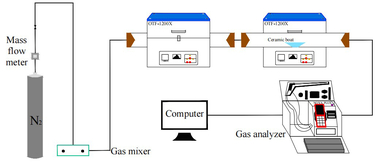

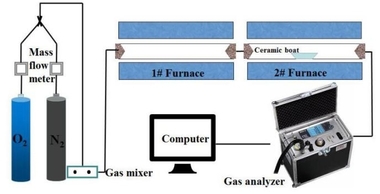

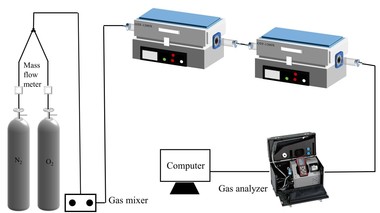

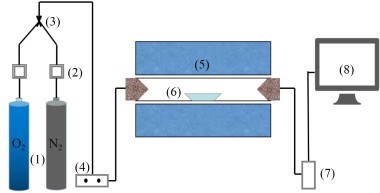

Even though RDF can be used as an alternative fuel to the cement industry, the utilization of RDF results in sulfur dioxide (SO2), nitrogen oxides (NOx) and particles emissions. Doping with additives are potential methods to ease these emissions. In this paper, the double-tube furnace experimental platform built in the laboratory was used to simulate the environment of the cement precalciner. The experimental research was carried out by way of fuel high-temperature and rapid injection. The generation characteristics of NOx, SO2 and CO during the pyrolysis of RDF mixed with CaO or CaCO3 were studied. The results show that mixing a certain amount of CaO can promote the generation of NOx, but the excess CaO can inhibit the generation of NOx. The effect of mixing CaCO3 on the generation of NOx and other gases in the RDF pyrolysis process is the same as that of mixing CaO. Mixing CaO or CaCO3 in the RDF pyrolysis process can reduce the release of SO2 and has the effect of fixing sulfur.

1 Introduction

China is a major producer of cement. With the increase of cement output year by year, the emission restriction conditions of pollutants such as NOx are becoming more and more strict [1, 2]. Refuse Derived Fuel (RDF) is a fuel made by sorting, crushing, drying, processing and molding garbage, which has the characteristics of high calorific value, stable combustion, and low secondary pollution. Therefore, RDF can be used as an alternative fuel to the cement industry [3-7]. The study of NOx generation and transformation of raw material components in RDF combustion process can help...