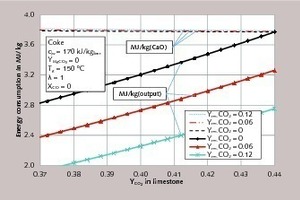

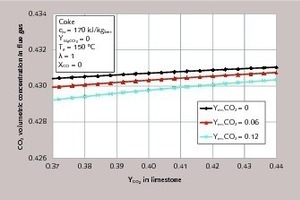

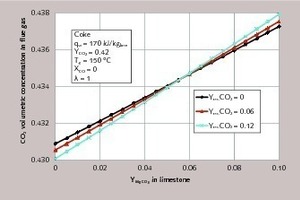

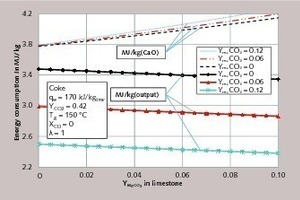

Energy consumption and CO2 content in the flue gas of normal shaft kilns:

Part 2: Influence of the limestone quality and the process parameters

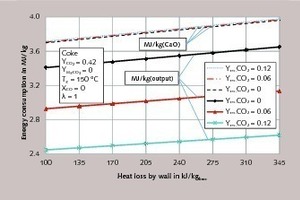

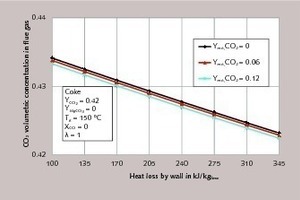

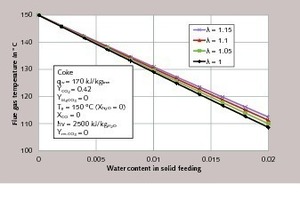

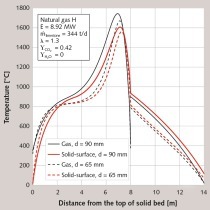

This Part 2 of the article describes the influence of limestone quality and the process parameters, CO content, kiln wall heat losses and moisture content of the solid feed materials. The influence of the air excess number and the balance equations were already explained in the preceding part of the article.

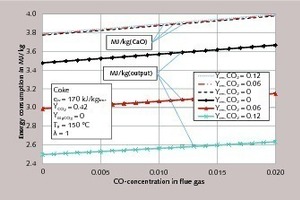

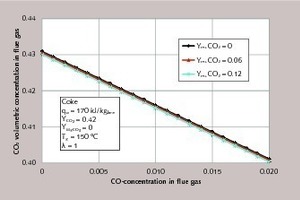

1 Influence of the CO concentration in the flue gas

The lime shaft kiln is used in the lime industry in order to produce so-called medium to hard-burnt lime. This type of kiln is also used in the sugar and soda industries because they need as a second product a flue gas with a high CO2 content. In the soda and lime industries it is sometimes necessary to use limestones with a high content of inert matter and magnesites.

Fig. 1 shows the effect that CO concentrations in the flue gas have on the energy consumption per kg of product (MJ/kgoutput) and per kg of calcium oxide (CaO) (MJ/kgCaO) for...