Evolution of heat during the synthesis of hydrosilicates in aerated concrete

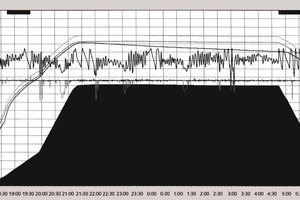

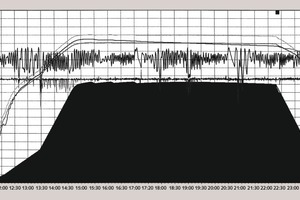

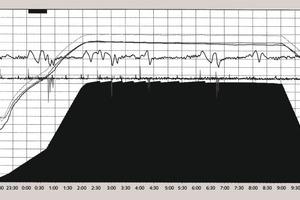

The heat evolved during the synthesis of 11.3 Å tobermorite from lime and quartz is 125 kJ/kg and the synthesis of xonolite is 50 kJ/kg, which raises the pressure and temperature in the autoclave. Recommendations are given below for controlling the composition of the hydrate and for reducing the consumption of steam during the autoclaving.

1 Introduction

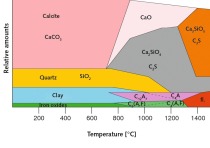

It is well known that heat is evolved during the reactions when calcium silicate hydrates are formed from calcium hydroxide and finely ground quartz in an autoclave. The exact values for the heat evolution of this process are very difficult to determine so at first the problem was approached theoretically. The results of these theoretical calculations are given by Babuschkin et al. [1]. The reaction for the formation of tobermorite from calcium hydroxide and quartz at a temperature of 179 °C has a reaction enthalpy of ΔHP = 30–31 kcal/mol. However, an enthalpy of ΔHP = 20–25 kcal...