The Pfister Wear Index: A new tool for predictive maintenance of Pfister DRW Rotor Weighfeeders

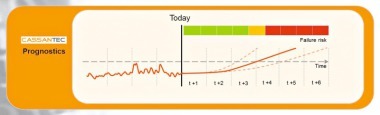

Machine life is rough in a cement plant. Unpredictable wear may cause expensive downtime when unscheduled maintenance becomes necessary. Sturdy materials and a smart predictive maintenance strategy are the key to uninterrupted production and highest customer satisfaction, the ultimate goal of Pfister engineers. Introducing the Pfister Wear Index, another important step towards flawless operations has been taken. At just one glance, system operators are provided with comprehensive information about the current status of wear parts which enables optimizing the maintenance intervals. The result: increased machine life and lower service and operational costs.

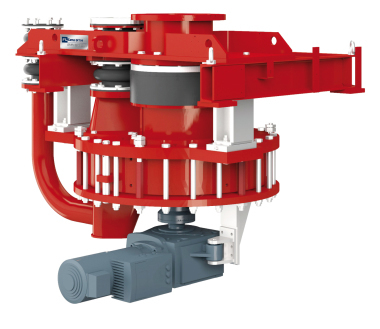

The rotor weighfeeder Pfister DRW is designed for dosing pulverized fuels such as petcoke, lignite or coal dust to the kiln in the cement making process. It is a compact system which integrates material extraction, weighing, dosing and material transfer into the pneumatic conveying line. Additionally, due to its dosing strategy ProsCon it allows for high short- and longterm accuracy as well as dosing stability.

To ensure runtime just as reliable as proper dosing, FLSmidth Pfister has developed several mechanisms to predict wear effects and to decrease them where wear is unavoidable. As part of its predictive maintenance strategy, Pfister further concentrated on analyzing the root causes for wear of the Pfister DRW by taking a tribosystem perspective and consequently developing the Pfister Wear Index.

Several factors contribute to wear: the intensity of usage, pneumatic conditions and the individual friction factor have to be taken in consideration. To clearly understand and analyze the reciprocity of effects, a scientific approach was needed. Tribology, or the science of interacting surfaces in relative motion, proved to be the key to develop a maintenance pre-warning system. Mini portions of pulverized fuel residues act as wear agents between parts moving relative to each other. Additionally, the pneumatic extraction of the pulverized fuel out of the rotor chambers causes abrasion. Combined, this leads to two major wear symptoms: surface alteration and metal loss.

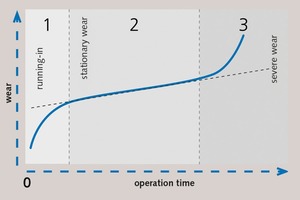

Analyzing wear drivers and their impact patterns led FLSmidth Pfister Head of R&D Dr.-Ing. Daniel Kasperek and his team to the development of model-based condition surveillance. In a standardized model, the typical phases of wear in correlation to operation time have been identified. Based on the typical curve of wear, the control system indicates the current condition of a running system and supports the customer in proper maintenance planning, thus reducing the risk of wear-triggered downtime.

Each cement plant is different, so the wear index is customized to individual field conditions. After each visual inspection of wear parts during maintenance, the wear index’s prediction quality is rated in three steps: wear index too high, correct, or too low. Each time, the result automatically re-calibrates the index, making individual prediction quality better and better over time.

//www.flsmidthpfister.com" target="_blank" >www.flsmidthpfister.com:www.flsmidthpfister.com