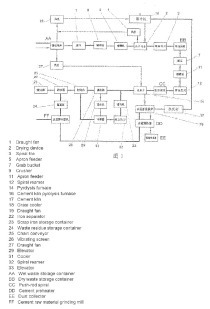

Heating complex of the cement kiln/lime kiln and high heat

consuming devices

(22) 17.05.2019

(43) 02.12.2020

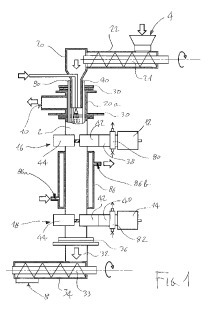

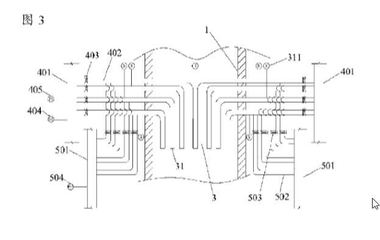

(57) The heating complex of a cement kiln/lime kiln and high heat plant consists of a separate pyrolysis reactor (A) with a raw material inlet (C) of disintegrated/crushed tires, the pyrolysis reactor (A) having an outlet (F) of hot steam mixture at the top, which is directly fed to the cement kiln (B) or to the lime kiln (B), or to a high heat plant. The pyrolysis reactor (A) at the bottom has a combined pyrolysis carbon outlet (H) with an outlet (D) of steel cord remains, at least the pyrolysis carbon outlet (H) being introduced into a cement kiln (B) or a lime kiln (B), or to a device with high heat consumption. The pyrolysis reactor (A) has an additional solid organic waste inlet (E) at the top. The pyrolysis reactor (A) is continuous with the contained mixing device and the heating device (I) of the pyrolysis reactor (A). The immediate introduction of the outlet (F) of the hot steam-gas mixture from the pyrolysis reactor (A) into the cement kiln (B) or into the lime kiln (B) or into the high heat plant is thermally insulated by insulation (K). The output of the disintegrator/tire crusher (J) is connected to the raw material input (C) of the disintegrated/crushed tires of the pyrolysis reactor (A).

(71) Stibranyi Ladislav Doc Ing CSC (SK)