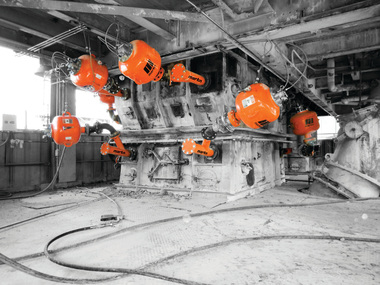

High Temp Air Cannon installation & service without production shutdown

Martin Engineering has announced a new technology for installing air cannons without a processing shutdown. The system allows specially trained technicians to mount the units on furnaces, preheaters, clinker coolers and in other high-temperature locations while production continues uninterrupted.

Martin Engineering developed the patent-pending Martin Core Gate to dramatically reduce expensive downtime associated with traditional installation methods, which require that high-heat processes be halted to allow core drilling and mounting of the cannons. The company has proven the technology in dozens of installations to date, helping bulk handlers maintain effective material flow and minimize shutdowns, improving efficiency while reducing lost production time.

The new system has been paired successfully with the firm’s Smart Nozzle Series, a family of air cannon nozzle designs which can be serviced or replaced during production, without removing the cannons themselves. Currently the only technology to safely install air cannons and replace nozzles during production, the specialized equipment and process require no confined space entry. With all installation and service performed from outside the vessel or process, the Core Gate system also contributes to a safer workplace by minimizing the difficulty and hazards of installation and maintenance.

To install air cannons in a running process, Martin technicians first conduct a thorough assessment of the accumulation patterns and blockages to identify the proper air cannon locations, then drill through the outer wall and weld the Core Gate in place. The core drill is mounted, checked for alignment and started, with progress monitored from a safe distance as it works its way through the refractory. As soon as the drill cuts through the refractory, the drill is backed out and an isolation shield is slid into place to protect workers from the severe environment. The Smart Nozzle assembly is mounted next – using an 8-bolt pattern that delivers excellent support – followed by the nozzle itself.

Replacing a conventional fan nozzle on existing equipment typically requires the removal of refractory material from around the nozzle opening, usually with a pneumatic hammer from inside the vessel. The process invariably weakens the surrounding refractory and renders it more susceptible to spider-webbing and subsequent cracking. In contrast, the Martin replacement system leaves the refractory undisturbed during service, and one worker can safely perform installations or maintenance from outside the vessel. The Martin Engineering design features a smaller footprint than typical fan jet nozzles, delivering a larger blast pattern than pipe nozzles or standard fan jet designs.

The new Core Gate and Smart Nozzle technologies are expected to find utility in cement manufacturing, coal-fired operations, ash handling and other high-temperature applications.

//www.martin-eng.com" target="_blank" >www.martin-eng.com:www.martin-eng.com