How refractory technologies can reduce costs and CO2 emissions

Cement production would be impossible without refractories. However, the potential for saving CO2 emissions through the selection of refractory material and design aligned to each kiln system is often underestimated. Optimal refractory solutions can extend operating times and prevent unscheduled kiln stops.

1 Introduction

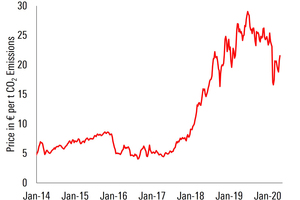

Cement making was and is all about costs. Massive investments to set up production facilities and huge amounts of costs for energy, including expenses for CO2 emissions, have to be paid back by an economic product. Growing environmental concerns linked to climate change and the depletion of fossil fuel reserves put cement and lime producers additionally in a challenging situation. Besides the main targets of producing high-quality products at low production costs, they must deal with strict environmental regulations worldwide which usually require additional investments and...

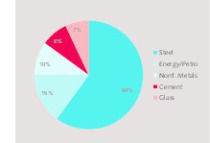

![1 Cost breakdown in cement production [6]](/uploads/images/2020/w300_h200_x524_y274_Process_Refratechnik_Refractory_technologies_Figure_1_Cost-breakdown-fb321803e416f3a6.jpeg)

![4 Design and functionality of the friction compensator. During the expansion of the green coloured brick ring vertically upwards in the direction of the arrow, the orange coloured brick ring moves horizontally. The horizontal movement pushes out a metal pin (not visible) and the volume expansion inside becomes visible [8]](/uploads/images/2020/w300_h200_x600_y619_Process_Refratechnik_Refractory_technologies_Figure_4_Radial-Compensator-0ea4dacd84706b91.jpeg)