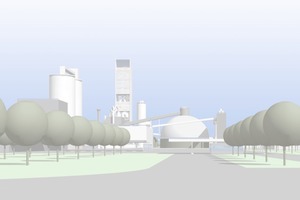

IBAU’s silo of tomorrow –

generating perfect flow, evolving into a work of art and providing new functions

The following article is the second part of Haver & Boecker’s “The cement plant of the future” series of articles (for part one see ZKG 1-2/2016, pp. 48–55). This part examines how silo technology and design can significantly contribute to the cement producer’s success. Some 40 years ago, the IBAU Central cone silo revolutionized the design of the silo. Forty years is a long time in the assessment of IBAU Hamburg, an EPC Engineering house located in Hamburg and owned 100 % by Haver & Boecker. Convinced it is time to “play it again, Sam”, IBAU is evolutionizing the silo.

1 Introduction

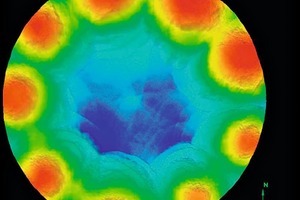

In the mid 1970s, the existing silo solutions for large capacity silos with a diameter of more than 10 m used the same process of aerating the entire silo floor in order to generate flow. The pneumatic discharge equipment of the time was not capable of completely emptying such silos. As a result, the material in the center provided core flow, but the material close to silo walls simply stuck. The results were poor silo flows and reclaim rates paired with high power consumptions for the compressed air.

With the introduction of the IBAU Central cone silo (Figure 1) the situation...