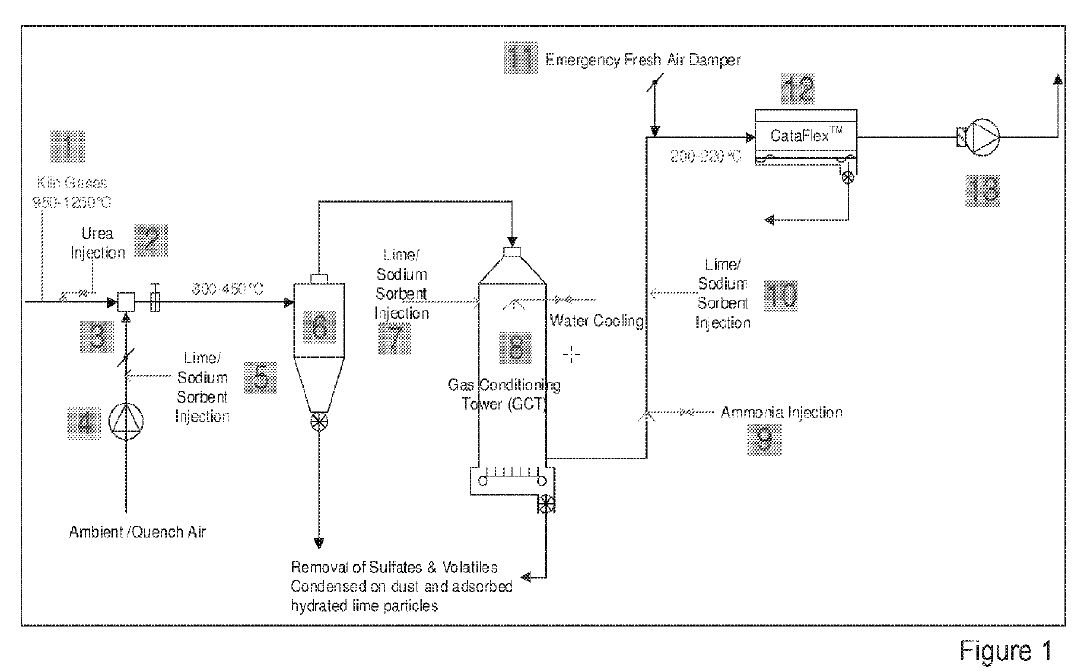

Industrial application of the kiln gas bypass quenching chamber and its new development

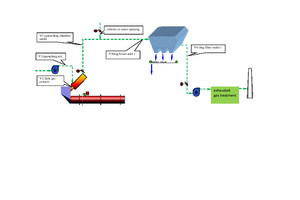

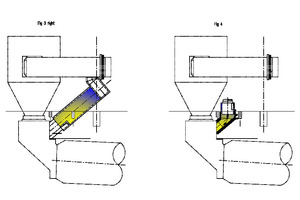

While it is easy to arrange a new bypass system in a new designed cement line, it is a challenge to implement it in existing production lines, due to limited space which makes it difficult to design. Considering this bottleneck, a second generation quenching chamber and bypass process has been developed to make it suitable for existing plants. It can be feasibly installed into all kinds of clinker production lines so as to improve the ratio of alternative fuel utilization.

1 Introduction and objectives

One important way to reduce CO2 emission is by steadily increasing the use of alternative fuels [1] to realize the target of CO2-neutral cement production by 2060 or even earlier. When using alternative fuels, it is necessary to install a bypass system [2, 3] to deal with the hazardous elements circulation of Cl, S, alkalies and especially Cl to avoid builds-up and coatings. It is easy to arrange a new bypass system in a new designed cement line; however, it is a challenge for existing production lines because of the limited space between the existing equipment...